Thyristor with deep energy level doping element drift area

A technology of doping elements and deep-level impurities, which is applied in the field of semiconductor power devices, can solve the problems of slow hole extraction by gate electrode control signal, thyristor turn-off failure, and accelerated gate electrode extraction, so as to reduce high-temperature leakage current and accelerate Turn-off process, effect of improving turn-off characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

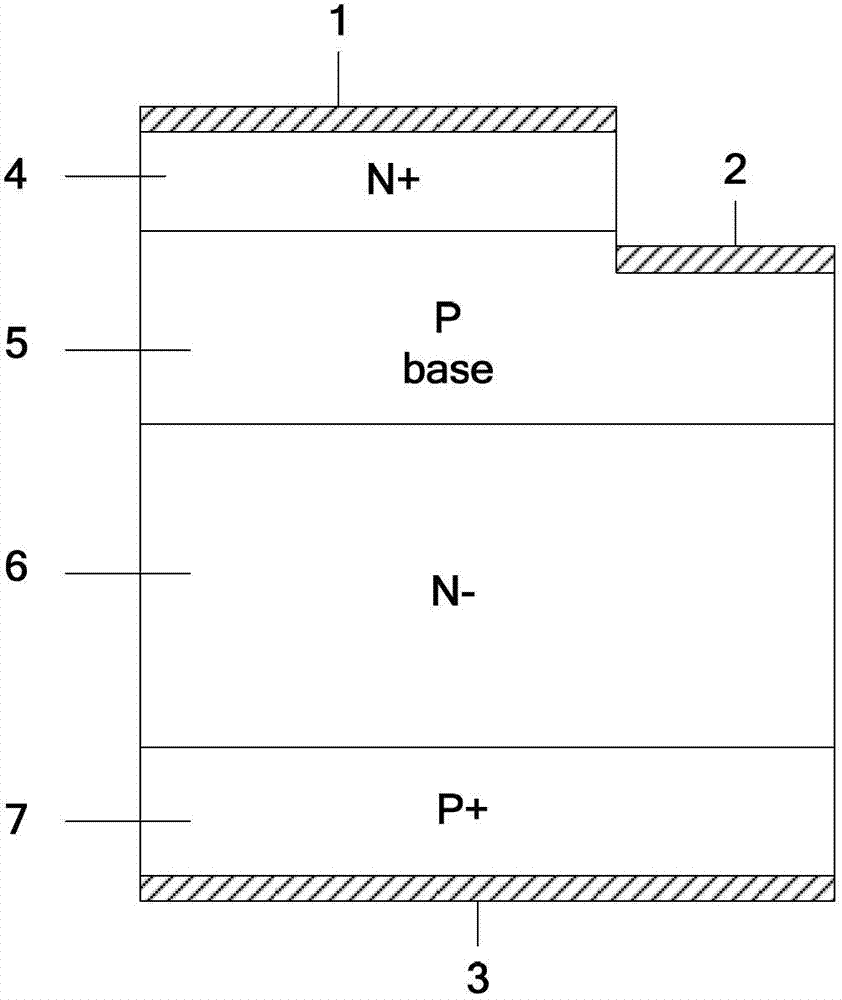

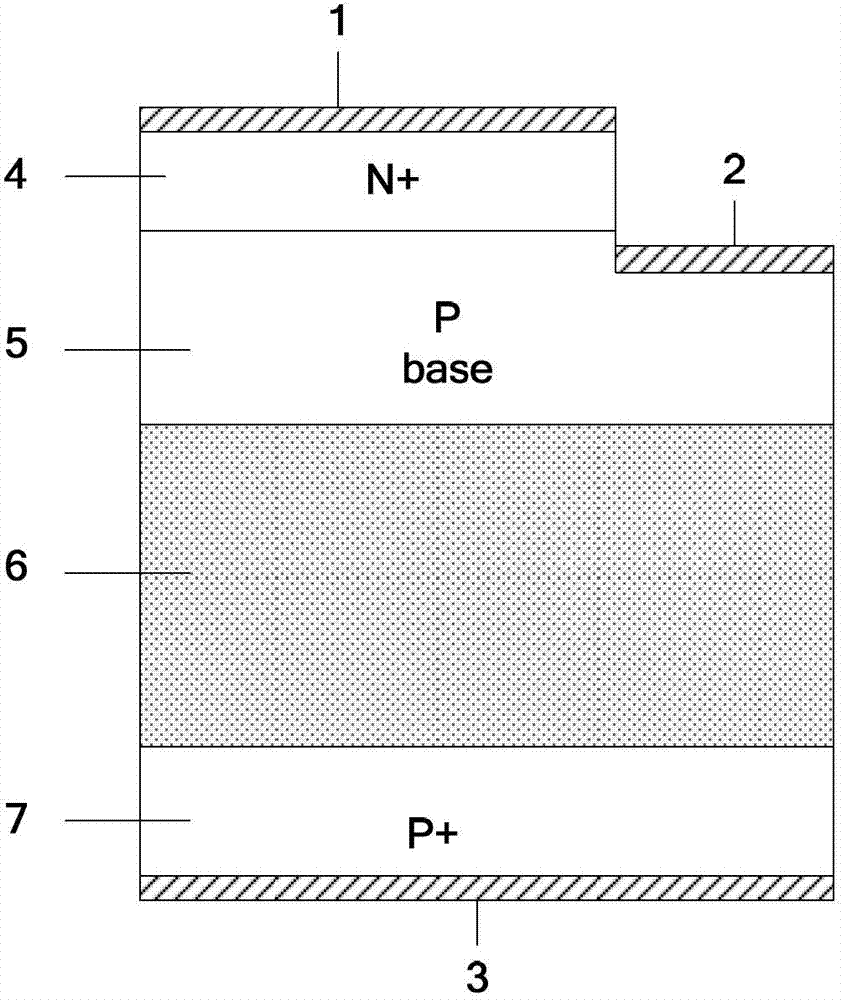

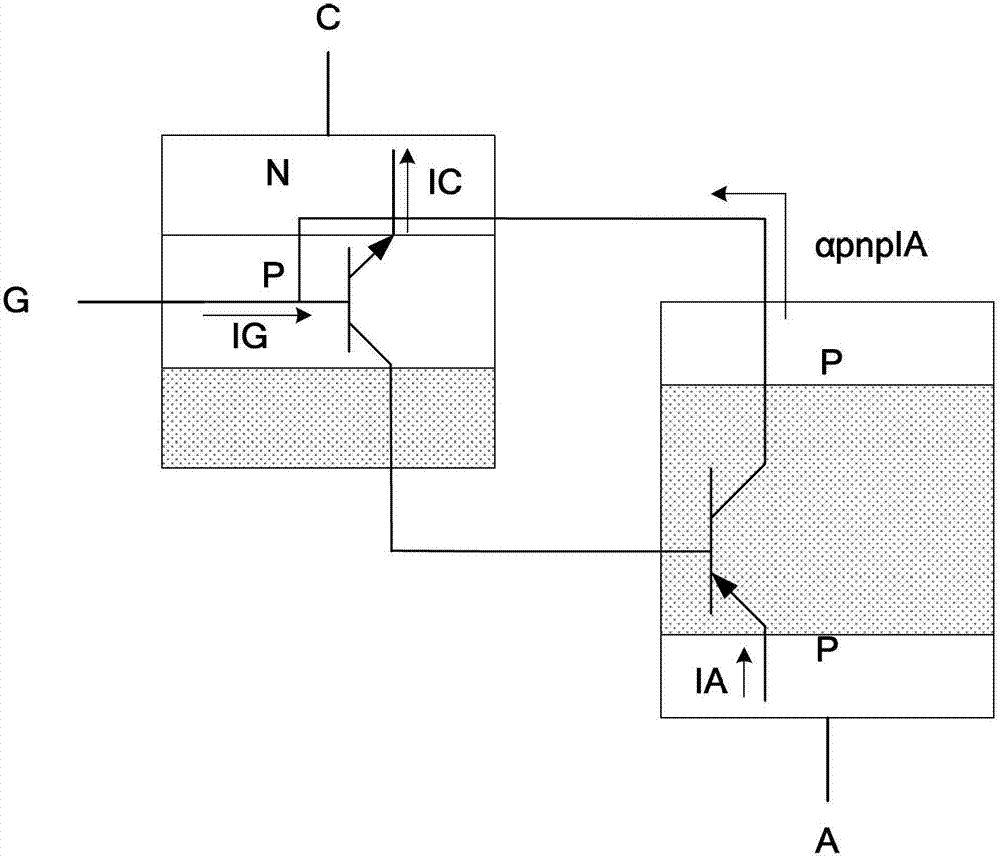

[0015] A thyristor with a deep-level doped element drift region, its cell structure is as follows figure 2 As shown, it includes a metallized cathode 1, a polysilicon gate electrode 2, a metallized anode 3, an N+ active region 4, a P-type base region 5, an N-drift region 6, and a P+ anode region 7; the metallized anode 3 is located in the P+ anode region 7, the N-drift region 6 is located above the P+ anode region 7, the P-type base region 5 is located above the N-drift region 6, and the P-type base region 5 is connected to the polysilicon gate electrode 2; the N+ active region 4 is located on the P-type base region Above the region 5, and connected to the metallized cathode 1; the N-drift region 6 is doped with deep-level impurity elements (specific doping elements include: sulfur, selenium, tellurium, gold or platinum).

[0016] It should be further explained that the N-drift region 6 can be fully or partially doped with deep-level impurity elements (that is, the implantati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com