Preparation method for infusorial earth/ titanium dioxide composite photocatalyst with nuclear/shell structure

A technology of titanium dioxide and shell structure, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of adsorption performance decline, diatomite pollution, etc., and achieve simple operation, high adsorption performance, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 0.38 mL of butyl titanate to 8 mL of absolute ethanol, stir for 2 minutes, add 0.1 g of diatomaceous earth powder to the lower alcohol, ultrasonicate and stir for 3 minutes each. Pour an anhydrous alcohol solution containing diatomaceous earth and butyl titanate into a crucible, and then place the crucible on top of a sealable container. The bottom of the sealable container is prefilled with 3 mL of distilled water. After sealing the container, put it into an oven, start heating to 150°C, the heating rate is 10-20°C / min, and keep it warm for 12 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 60°C for 8 hours.

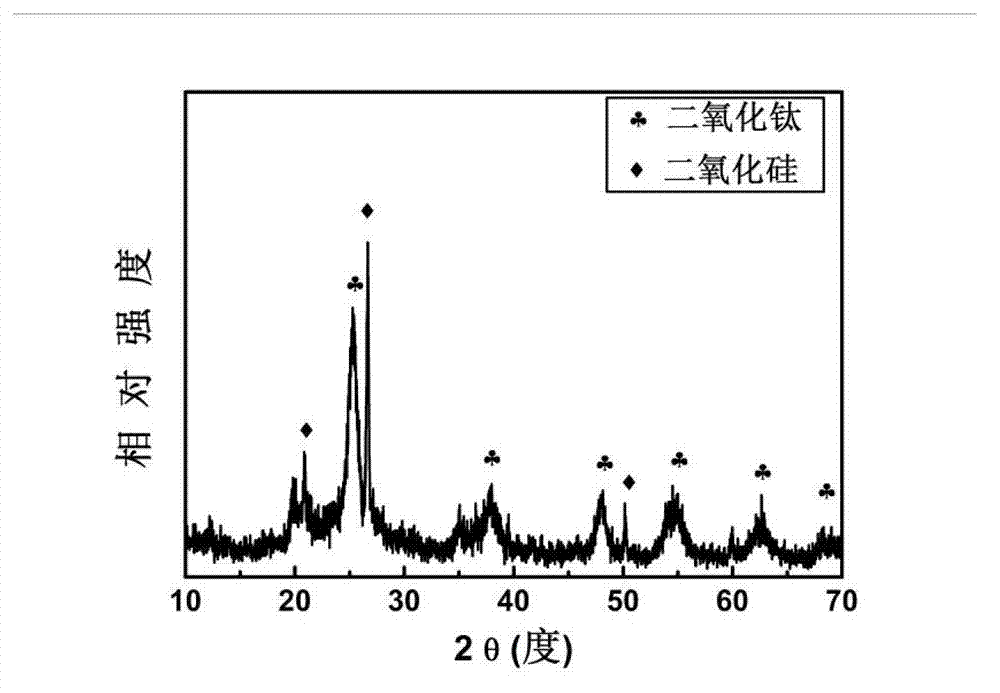

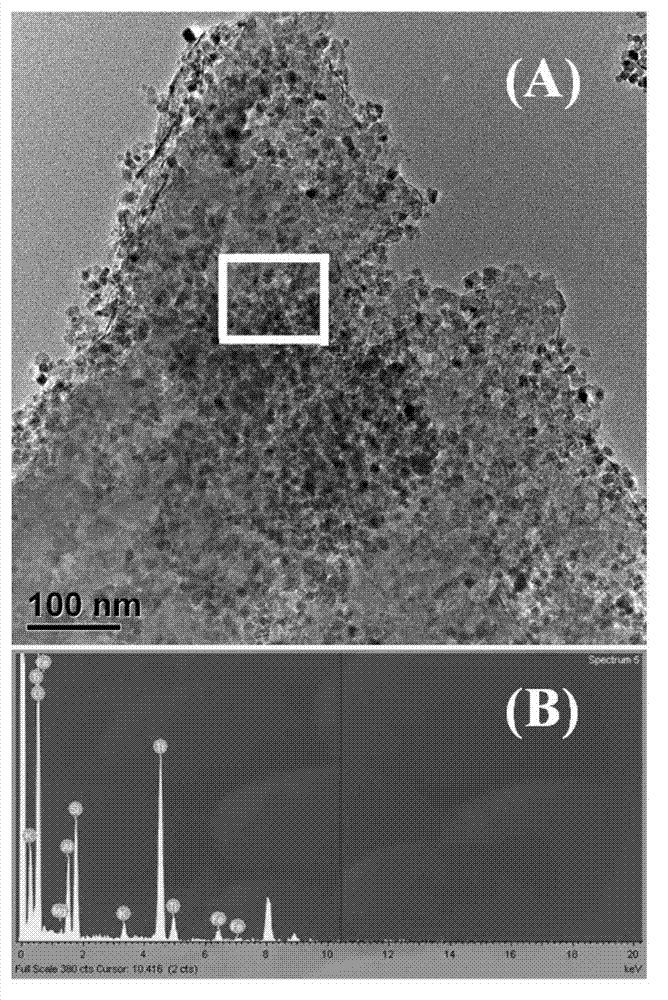

[0036] figure 1 The X-ray diffraction pattern of the diatomite / titanium dioxide composite photocatalyst of the core / sh...

Embodiment 2

[0039] Add 0.19 mL of butyl titanate to 8 mL of absolute ethanol, stir for 2 minutes, add 0.1 g of diatomaceous earth powder to the lower alcohol, ultrasonicate and stir for 3 minutes each. Pour an anhydrous alcohol solution containing diatomaceous earth and butyl titanate into a crucible, and then place the crucible on top of a sealable container. The bottom of the sealable container is prefilled with 3 mL of distilled water. After sealing the container, put it into an oven, start heating to 200°C, the heating rate is 10-20°C / min, and keep it warm for 6 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 60°C for 8 hours.

Embodiment 3

[0041]0.14 mL of titanium tetrachloride and 8 mL of absolute ethanol were formulated into an alcohol solution of titanium, and 0.1 g of diatomaceous earth powder was added to the above solution, ultrasonic and stirred for 3 minutes each. Pour an anhydrous alcohol solution containing diatomaceous earth and titanium tetrachloride into a crucible, and then place the crucible on top of a sealable container. The bottom of the sealable container is prefilled with 3 mL of distilled water. After sealing the container, put it into an oven, start heating to 150°C, the heating rate is 10-20°C / min, and keep it warm for 12 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 60°C for 8 hours.

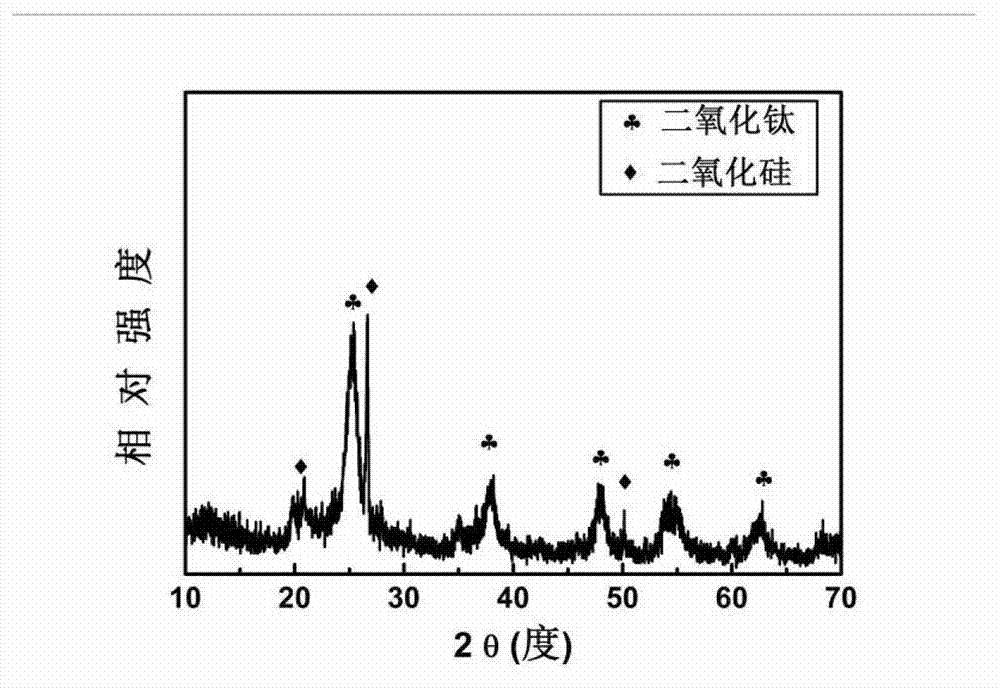

[0042] image 3 The X-ray diffraction pattern of the diatomite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com