Processing component for cutting hard and brittle materials and cutting component

A technology of hard and brittle materials and compositions, applied in the direction of stone processing tools, stone processing equipment, lubricating compositions, etc., can solve the problems of increasing costs, reducing the use efficiency of those skilled in the art, and adding one more processing step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the processing composition and cutting composition of the present invention is not particularly limited, and a general mixing method can be used, such as mixing hexagonal boron nitride, polyols and surfactants evenly to form a processing composition , and then, add the processing composition into the abrasive particles, and keep stirring until uniform, and the cutting composition can be formed.

[0030] The method for cutting hard and brittle materials of the present invention is to contact the hard and brittle materials with the above-mentioned processing composition, and cut the hard and brittle materials into a plurality of hard and brittle chips with cutting surfaces by a cutting device. The processing composition makes the hard and crisp pieces easy to peel off from each other and difficult to stick.

[0031] The cutting device is well known to those skilled in the art, so details will not be repeated here.

[0032] Preferably, the hard a...

Embodiment 1

[0037] Weigh 0.02 parts by weight of hexagonal boron nitride, 2.033 parts by weight of diethylene glycol, 77.64 parts by weight of propylene glycol, 5.082 parts by weight of polyethylene glycol (model PEG-600), 1.016 parts by weight of SINOPOL263, 0.102 parts by weight SW-923, 0.102 parts by weight of SAS-60, 0.203 parts by weight of triethanolamine, 0.02 parts by weight of phthalate, 0.183 parts by weight of octanoic acid and 15.25 parts by weight of water are stirred and mixed at room temperature to obtain processed Composition.

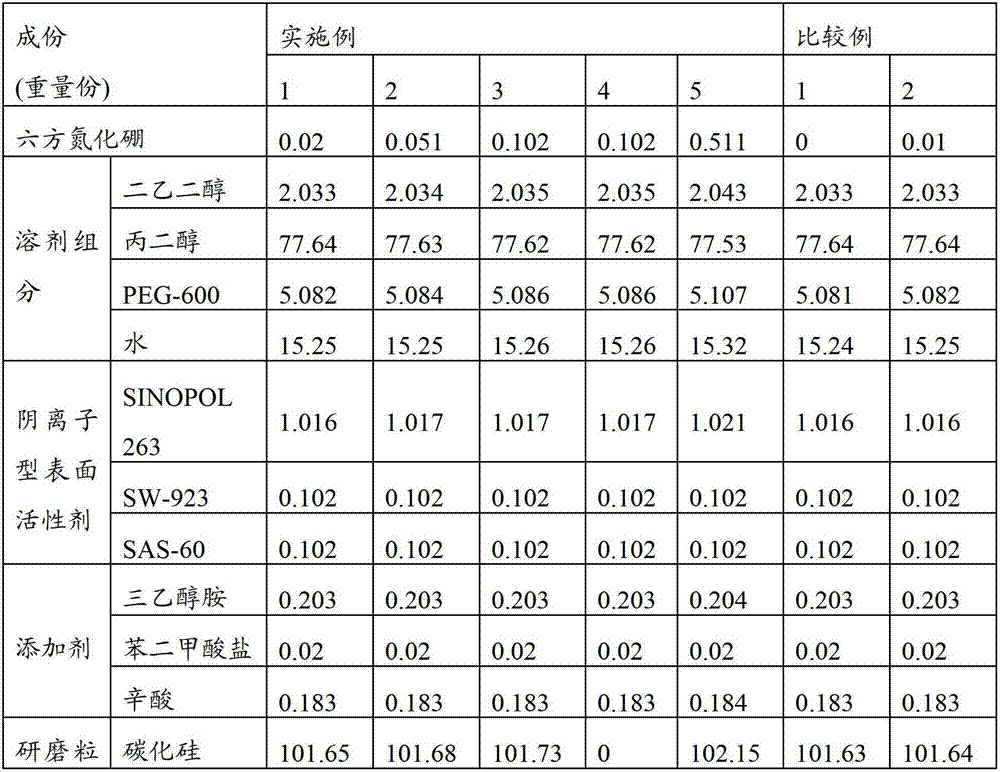

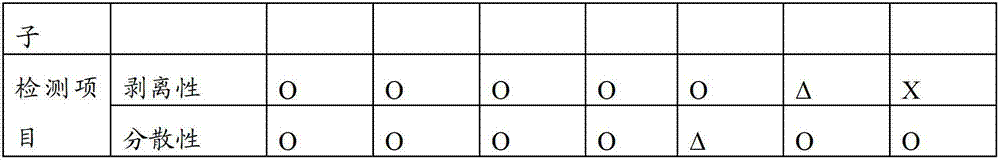

Embodiment 2~5 and comparative example 1~2

[0039] Examples 2 to 5 and Comparative Examples 1 to 2 prepared the processed composition in the same steps as in Example 1, the difference being that the types of hexagonal boron nitride, solvent components, surfactants and additives were changed and content, as shown in Table 1. The processed composition was evaluated for each test item, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com