Device and method of growing 500-1000mm long bismuth germanate crystals by descent method

A technology for growing crystals and bismuth germanate, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., and can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

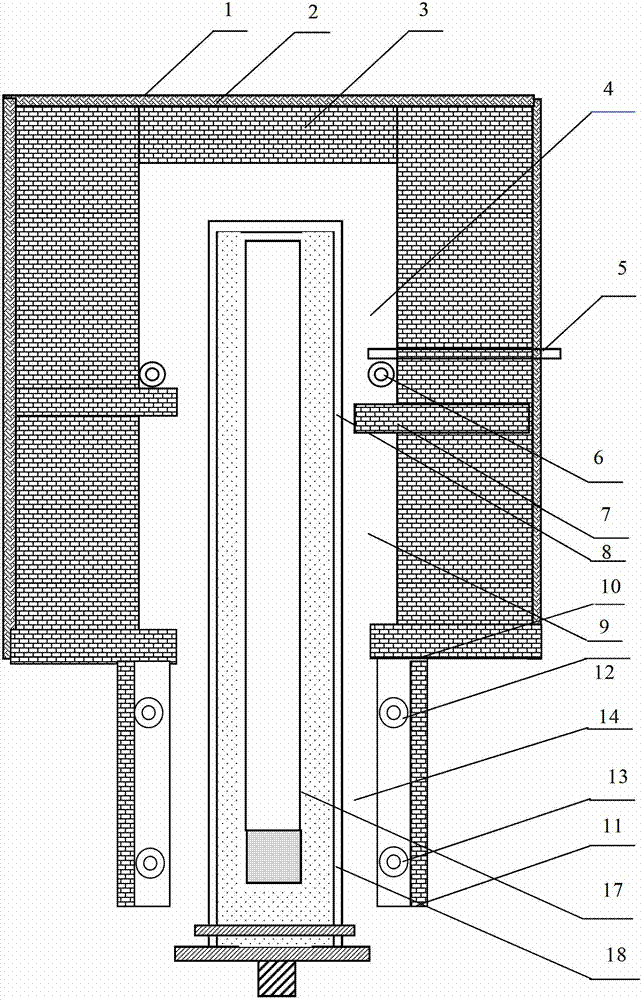

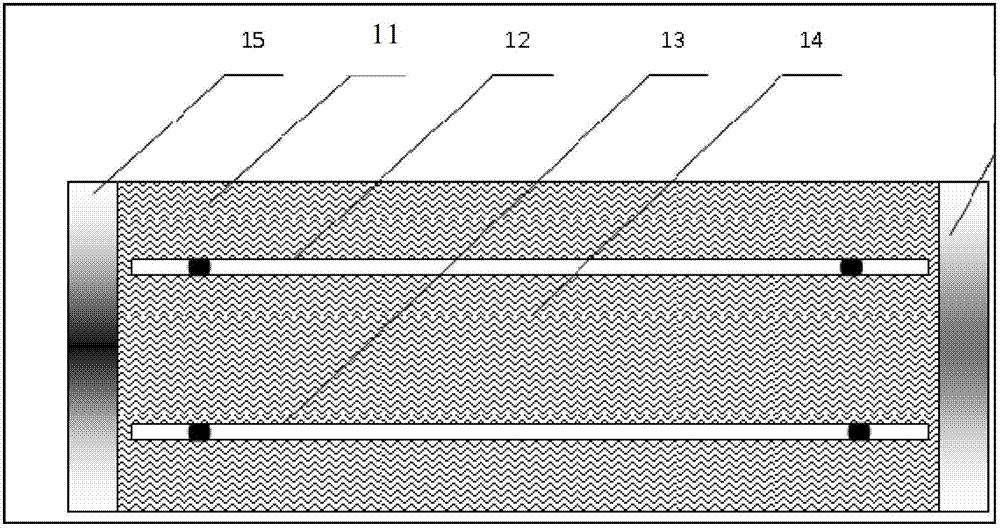

Method used

Image

Examples

Embodiment 1

[0046] Prepare 600mm long bismuth germanate crystals, the specific preparation method is as follows:

[0047] Mix bismuth trioxide and germanium dioxide with a purity of more than 4N according to the stoichiometric ratio of 2:3, put them in a platinum crucible, raise the temperature above the melting point and keep it warm for about 10-60 minutes to completely melt the raw materials and quickly Inject it into a mold and cool down to obtain a polycrystalline ingot.

[0048] A 3-layer platinum sheet with a thickness of 0.16mm is made into a section of 30×30mm 2 , A cuboid crucible with a length of 700mm.

[0049] Choose the thickness as 8mm and the outer section as 80×90mm 2 , 620mm long cuboid aluminum oxide down-leading crucible; and choose a size of 60×30×70mm 3 Crystals of bismuth germanate were cut, ground, and cleaned for use as seeds.

[0050] Put the seed crystal and the prepared raw materials into a 700mm long platinum crucible with top and bottom openings or a plat...

Embodiment 2

[0053] Prepare 600mm long bismuth germanate crystals, the specific preparation method is as follows:

[0054] Select the ready-made bismuth germanate crystal, cut and grind it into the required size and shape, and use it as the crystal block of the growth raw material after cleaning.

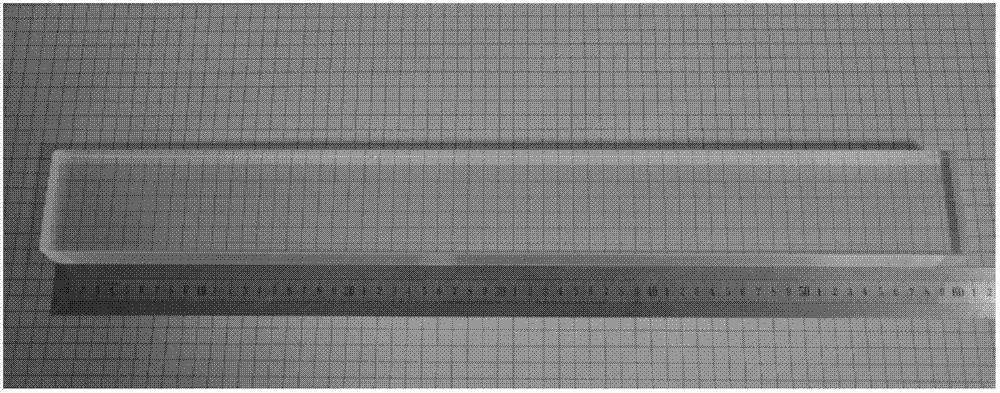

[0055] Other steps of embodiment 2 are as described in embodiment 1, finally make described 600mm long bismuth germanate crystal (as image 3 ).

Embodiment 3

[0057] Prepare 600mm long bismuth germanate crystals, the specific preparation method is as follows:

[0058] Control the temperature of the heating element of the furnace structure system at about 1280°C, and control the temperature of the heating element of the auxiliary heating system at about 480°C, so that the temperature field of the entire device is most suitable for the growth of crystals, and control the temperature of the alumina-leading crucible The vertical drop rate was 1.0 mm / hour and the temperature gradient at the crystal growth interface was 40 Kelvin / centimeter (K / cm).

[0059] Other steps of embodiment 3 are as described in embodiment 1 or 2, finally make described wide plate shape bismuth germanate crystal (such as image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com