High-speed centrifugal drying method and drying system for implementing method

A technology of high-speed centrifugation and drying method, which is applied in the direction of drying solid materials, drying gas arrangement, drying, etc., which can solve the problems of unstable drying quality, low work efficiency, and low drying efficiency, and achieve convenient control and management and high drying speed. The effect of fast and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

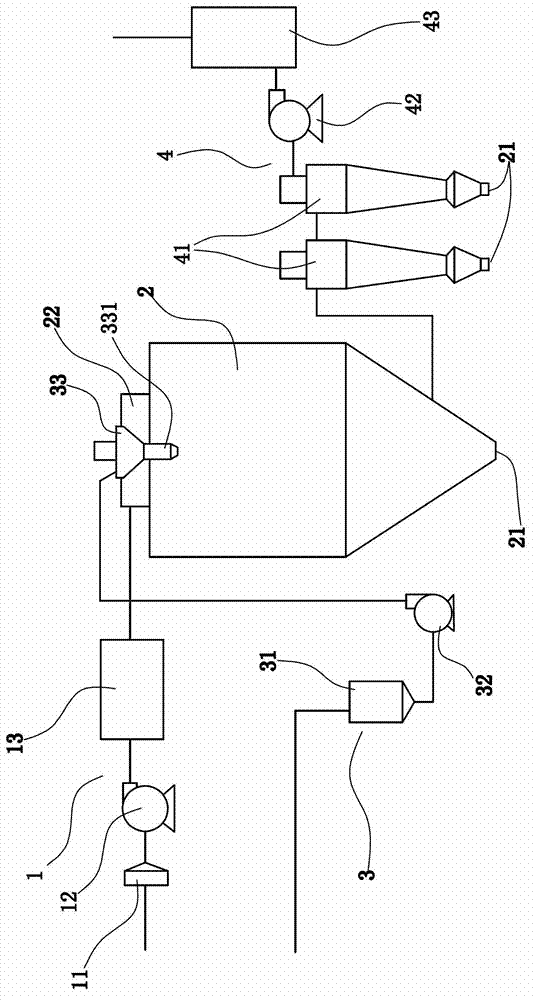

[0031] Example: see figure 1 , a high-speed centrifugal drying method of the present invention, it comprises the following steps:

[0032] (1) A hot air drying device 1 is provided to generate a high-speed hot air flow for drying materials, and the hot air drying device 1 is connected to the drying tower 2 through a pipeline;

[0033] (2) A to-be-dried material conveying device 3 for conveying the to-be-dried emulsion, suspension, paste or solution form material is provided, and the to-be-dried boring conveying device is connected to the drying tower 2 through a pipeline;

[0034] (3) A tail gas filtering device 4 is provided for material recovery and purification of the tail gas generated after material drying in the drying tower 2, and the tail gas filtering device 4 is connected to the drying tower 2 through a pipeline;

[0035] (4) The hot air drying device 1 is working to filter the air to form a high-speed airflow, and spray it into the drying tower 2 through a pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com