Preparation method of transmission electron microscopy sample for in-situ electrical testing

A transmission electron microscope sample and electrical technology, which is applied in the preparation of test samples and other directions, can solve the problems of difficulty in preparing TEM samples for in-situ electrical testing, and achieves the effect of solving the problem of electrical connection, simple preparation process, and reducing the difficulty of preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the transmission electron microscope sample that the present invention is used for in-situ electric test comprises the following steps:

[0028] Step 1. Using the FIB etching process, the top tip of the metal probe is flattened to form a platform with a flat surface, which is used as a preparation substrate for semiconductor devices at both ends.

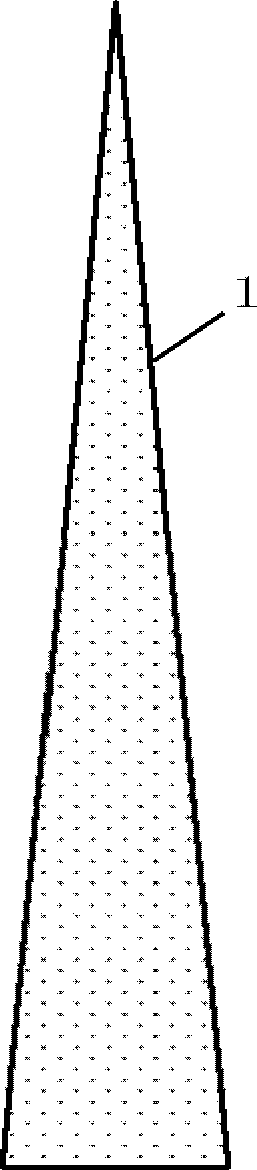

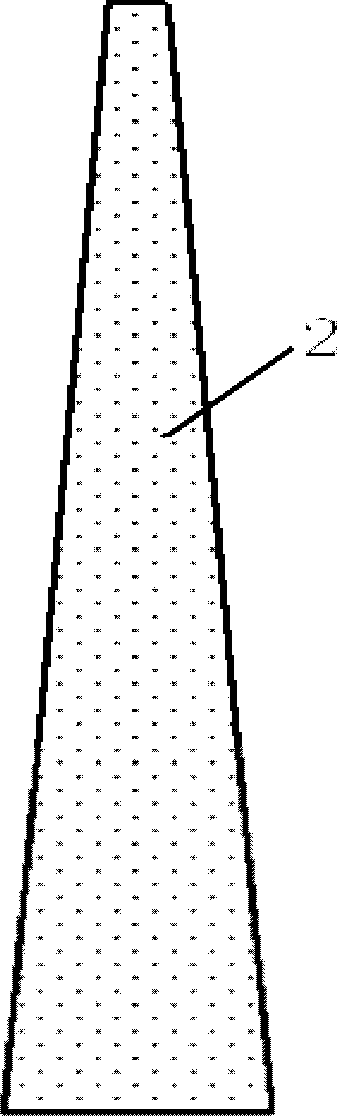

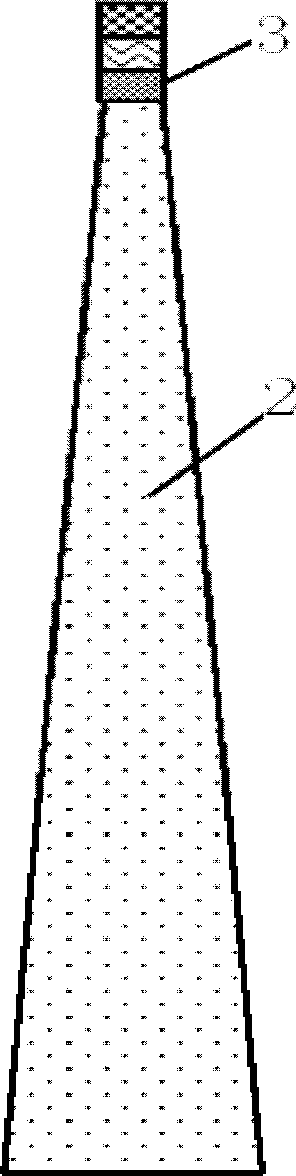

[0029] Such as figure 1 As shown, it is the metal probe 1 before treatment. The top of the W needle with a diameter of 3 mm is processed into a circular table with a diameter of 10 μm by using the FIB etching process, and by adjusting the acceleration voltage and the etching rate during the FIB ion etching process Current to ensure the flatness of the surface of the circular table, such as figure 2 Shown is a metal probe 1 forming a flat surface platform 2 .

[0030] Step 2: Using a semiconductor thin film preparation process, a semiconductor device with both ends is prepared on the top platform o...

Embodiment 2

[0040] In this example, the same process steps as in Example 1 were used to prepare TiN / HfO on the Pt probe 2 / TiN RRAM, TiN and HfO 2 The thin film materials are respectively obtained by means of magnetron sputtering and atomic layer deposition, and the thicknesses are 50nm / 10nm / 50nm respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com