High-purity manganese sulfide and method for preparing the same

A technology of manganese sulfide and hydrogen sulfide, applied in chemical instruments and methods, inorganic chemistry, manganese compounds, etc., can solve the problems of low product purity, inability to industrialize large-scale production, and difficulty in washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

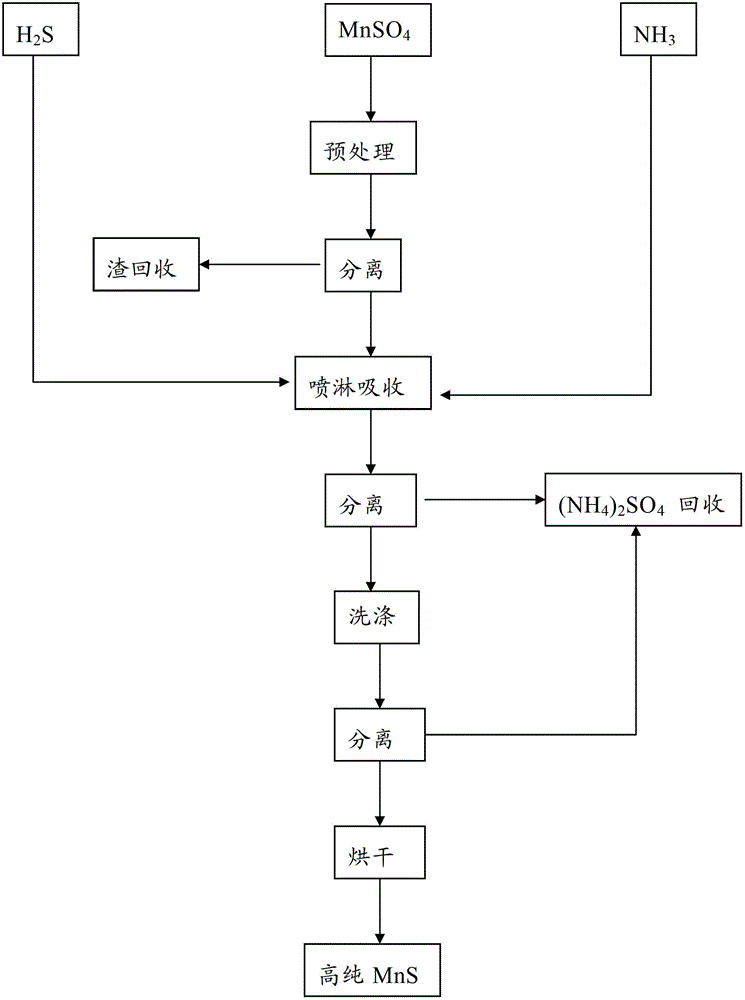

[0028] The preparation method of manganese sulfide of the present invention, realizes by following chemical reaction:

[0029] MSO 4 +MnS→MS+MnSO 4

[0030] (M: Co, Ni, Cu, Zn, Pb, As, Fe, etc.)

[0031] MnSO 4 +2NH 3 / H 2 O+H 2 S↑→MnS+(NH 4 ) 2 SO 4 +2H 2 o

[0032] The present invention uses manganese sulfate as a starting raw material, separates and removes the content of each heavy metal element in the raw material manganese sulfate through pretreatment to further control the content of each metal element in the product manganese sulfide element, and finally obtains high-purity manganese sulfide.

[0033] In a specific embodiment, the production method of manganese sulfide of the present invention, comprises the steps:

[0034] (1) Pretreatment step: Add manganese sulfide to manganese sulfate solution with a concentration of 50g / L-300g / L, and then separate solid and liquid to obtain purified manganese sulfate solution and solid;

[0035] In a preferred embodim...

Embodiment 1

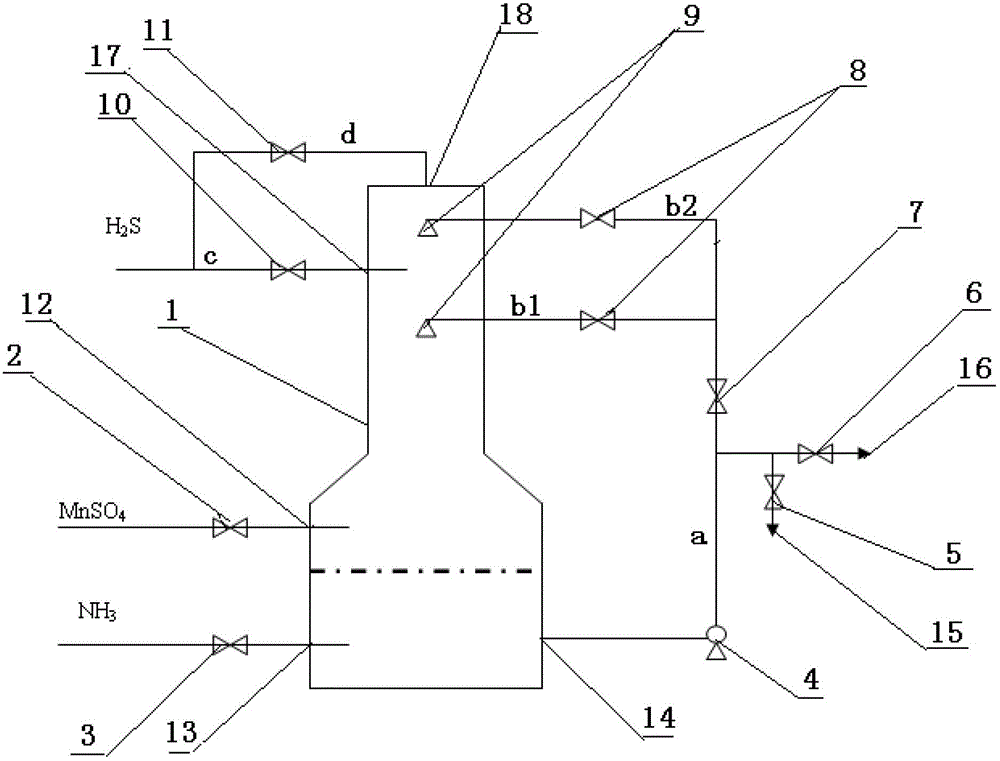

[0064] refer to figure 1 and figure 2 , the present embodiment manganese sulfide is prepared through the following steps:

[0065] (1) Pretreatment step: prepare 20 kg of commercially available feed-grade manganese sulfate into a manganese sulfate solution with a concentration of 100g / L, then add 30g of MnS to the above solution, heat the mixture to 90°C after mixing, and then stir to react After 2 hours, solid-liquid separation by filtration is carried out, valuable metals are recovered from the solid, and the clarified liquid enters the next step of operation.

[0066] (2) Spray reaction step: open the manganese sulfate valve 2 to send the above-mentioned pretreated manganese sulfate solution into the spray absorption reactor through the manganese sulfate feed port 12, and then open the circulation pump 4 to circulate, wherein the circulation pump The flow rate is 4m 3 / h, then turn on H 2 S valve 10, adjust H 2 The flow of S is 1.3m 3 About / h, open the liquid ammoni...

Embodiment 2

[0069] refer to figure 1 and figure 2, the present embodiment manganese sulfide is prepared through the following steps:

[0070] (1) Pretreatment step: liquid SO 2 Manganese sulfate solution obtained by reacting with low-grade manganese dioxide, wherein the quality of manganese sulfate is 200kg, MnSO 4 The concentration of the solution is 120g / L, then add 400g MnS to the above solution, mix and heat the mixed solution to 95°C, then stir and react for 3 hours, then carry out solid-liquid separation by filtration, recover valuable metals from the solid, and enter the clarified liquid into Next step.

[0071] (2) Spray reaction step: open the manganese sulfate valve to send the above-mentioned pretreated manganese sulfate solution into the spray absorption reactor through the manganese sulfate feed port 12, and then turn on the circulation pump 4 for circulation, wherein the flow rate of the circulation pump 100m 3 / h, then turn on H 2 S valve 10, adjust H 2 The flow of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com