Continuous dry anaerobic fermentation method

A dry anaerobic fermentation and anaerobic fermentation technology, applied in the field of continuous dry anaerobic fermentation, can solve the problems of low degradation efficiency and degradation degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

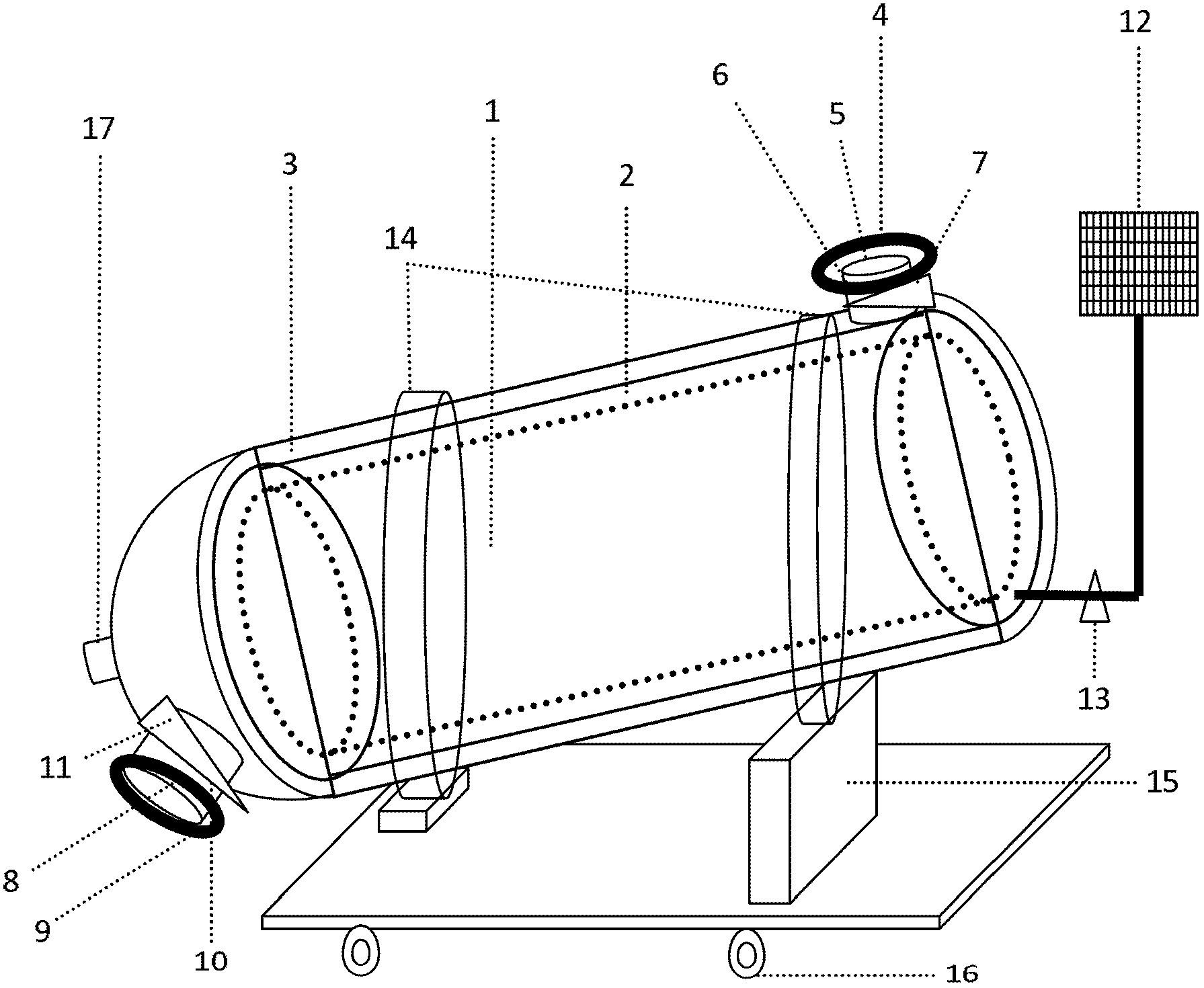

Image

Examples

Embodiment 1

[0097] According to the sorting standard of urban domestic waste, the organic waste such as kitchen, fruit and vegetable is sorted out, and the organic solid waste such as fruit and vegetable waste and straw collected in the bazaar is crushed to make the particle size of the material less than 5cm. After determination, the basic shape of the material is shown in Table 1:

[0098] Table 1 Basic Properties of Raw Materials

[0099]

[0100] Mix according to 28.3% (dry weight) of food waste, 19.7% (dry weight) of fruit and vegetable waste, 17.2% (dry weight) of straw, and 34.8% (dry weight) of livestock and poultry manure, so that the moisture content of the material is 75%. The volume of the reaction device is 130L.

[0101]Add the mixed material into the continuous dry anaerobic fermentation device, the loading volume is 100L, then close the reaction device, ferment for 35 days, then add 3.25L of fresh material to the reaction device every 24h, and at the same time, pass th...

Embodiment 2

[0103] According to the sorting standard of urban domestic waste, the organic waste such as kitchen, fruit and vegetable is sorted out, and the organic solid waste such as fruit and vegetable waste and straw collected in the bazaar is crushed so that the particle size of the material is less than 5cm. After determination, the basic shape of the material is shown in Table 1:

[0104] Table 2 Basic Properties of Raw Materials

[0105]

[0106]

[0107] Mix according to 28.3% (dry weight) of food waste, 19.7% (dry weight) of fruit and vegetable waste, 17.2% (dry weight) of straw, and 34.8% (dry weight) of livestock and poultry manure, so that the moisture content of the material is 75%. The volume of the reaction device is 40m 3 .

[0108] Add the mixed material into the continuous dry anaerobic fermentation device, the loading volume is 30m 3 , then close the reaction device, ferment for 35 days, and then add fresh material 1m to the reaction device every 24h 3 , at th...

example 1

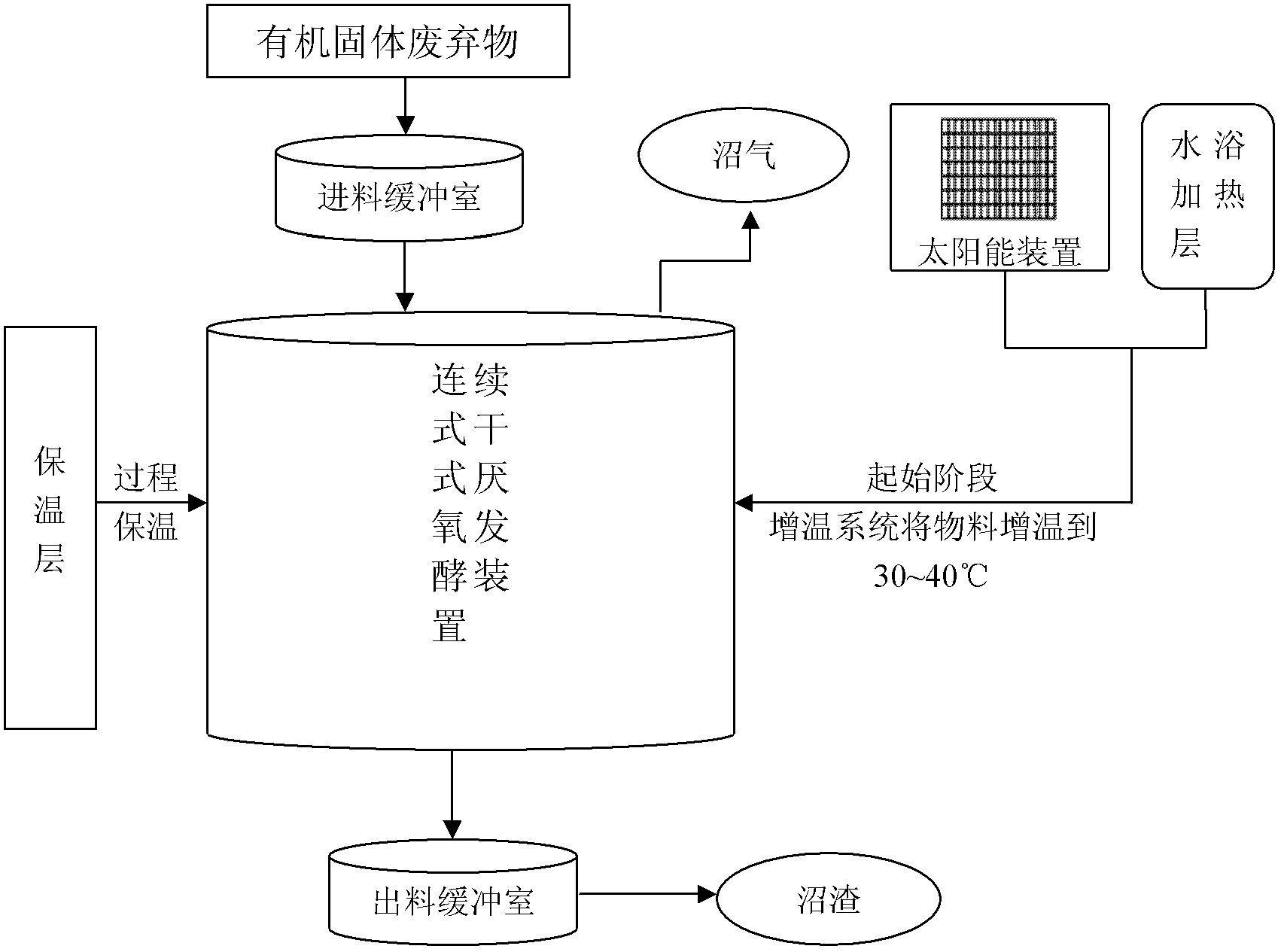

[0109] After the stable operation of Example 1, 3.25L of fresh material can be added every day. In the treatment of Example 2, during the stable operation period, 1m of fresh organic solid waste can be processed daily. 3 . This is achieved through the setting of the feed and discharge buffer chambers. The feed buffer chamber set at the feed end and the discharge buffer chamber set at the discharge end realize the function of continuous operation, thereby realizing the daily production and clearing of organic solid waste.

[0110] Through the solar device and the water bath heating layer installed in the continuous fermentation device, the solar device provides the heat source, and the water bath layer realizes the heat transfer to heat the materials in the main warehouse, ensuring that the anaerobic fermentation is performed when the temperature is lower than 20°C. The temperature of the device rises to 36°C ± 1°C, and the temperature of the fermentation system is maintained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com