Preparation method of protamine sulfate

A technology of protamine sulfate and sulfuric acid solution is applied in the field of biomedicine, can solve the problems such as the inability to meet the quality requirements of protamine sulfate, and achieves the effects of low cost, increased titer and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The protamine essence of salmon is crushed, extracted with water, filtered, and the filtrate is precipitated with ethanol to obtain the crude product of protamine sulfate, which is then subjected to the following operations:

[0030] (1) Sulfuric acid extraction process

[0031] In 300.5g of protamine sulfate crude product, add 3 volume % sulfuric acid solution 601ml, stir for 2 hours, filter, get filtrate;

[0032] The filtrate was precipitated with 1800ml of 95% ethanol. After 12 hours, the upper layer of ethanol was discarded, the lower layer of sediment was filtered, the filtrate was discarded, and the solid weighed 60g;

[0033] (2) Heating extraction process

[0034] Add 240ml of water to the solid and stir to dissolve, continue to heat the solution to 65°C, keep it warm for 30 minutes, filter to get the filtrate, discard the filter residue, and measure the volume of the filtrate to 240ml;

[0035] Add 720ml of 95% ethanol to precipitate, discard the upper layer...

Embodiment 2

[0042] Change the 3 volume % sulfuric acid solution in the step (1) in Example 1 to a 6 volume % sulfuric acid solution; change the heating temperature of the solution in the step (2) to 70°C; change the low temperature treatment in the step (3) The temperature was changed to 3° C., and the other process conditions were the same as in Example 1, and finally 26.78 g of the refined product was obtained.

Embodiment 3

[0044] Change the 3 volume % sulfuric acid solution in step (1) in Example 1 to 9 volume % sulfuric acid solution; change the heating temperature of the solution in step (2) to 75 ° C; change the low temperature treatment in step (3) to The temperature was changed to 14° C., and the other process conditions were the same as in Example 1, and finally 27.06 g of the refined product was obtained.

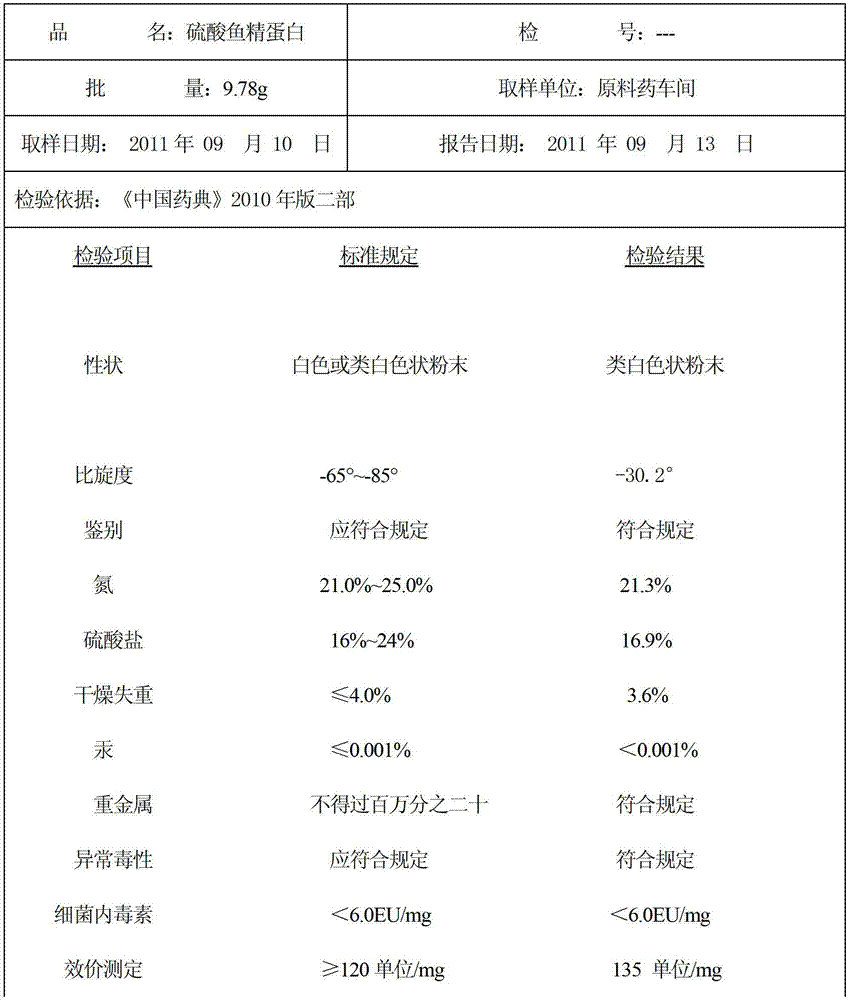

[0045] Traditional production process:

[0046] Qingdao Kangyuan Pharmaceutical Co., Ltd.

[0047] Protamine Sulfate Finished Product Inspection Report

[0048]

[0049]

[0050] Adopt the production technique of the embodiment of the present invention 1:

[0051] Qingdao Kangyuan Pharmaceutical Co., Ltd.

[0052] Protamine Sulfate Finished Product Inspection Report

[0053] Batch number: KP110901

[0054]

[0055]

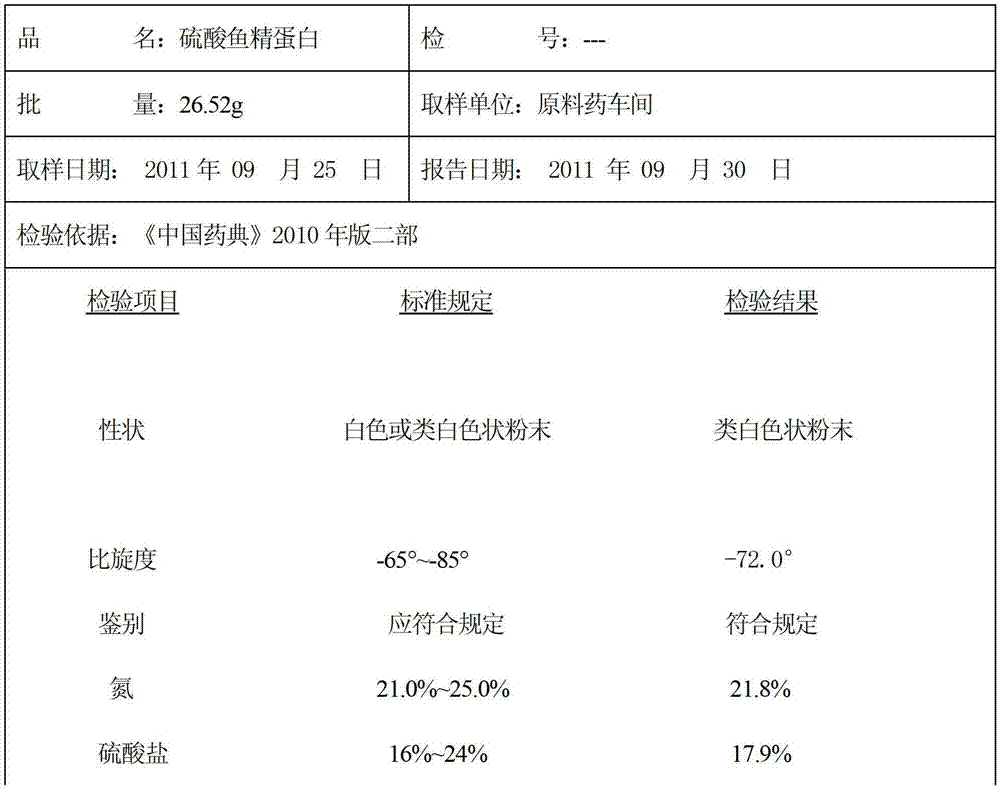

[0056] Adopt the production technique of the embodiment of the present invention 2:

[0057] Qingdao Kangyuan Pharmaceutical Co., Ltd.

[0058] Protamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com