System and method for testing barycenter of road roller steel wheel and vibration amplitude uniformity of road roller steel wheel

A testing system and technology of road rollers, applied in the testing of machines/structural components, vibration measurement in solids, static/dynamic balance testing, etc., can solve problems such as the complexity of the process of measuring the amplitude of road rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

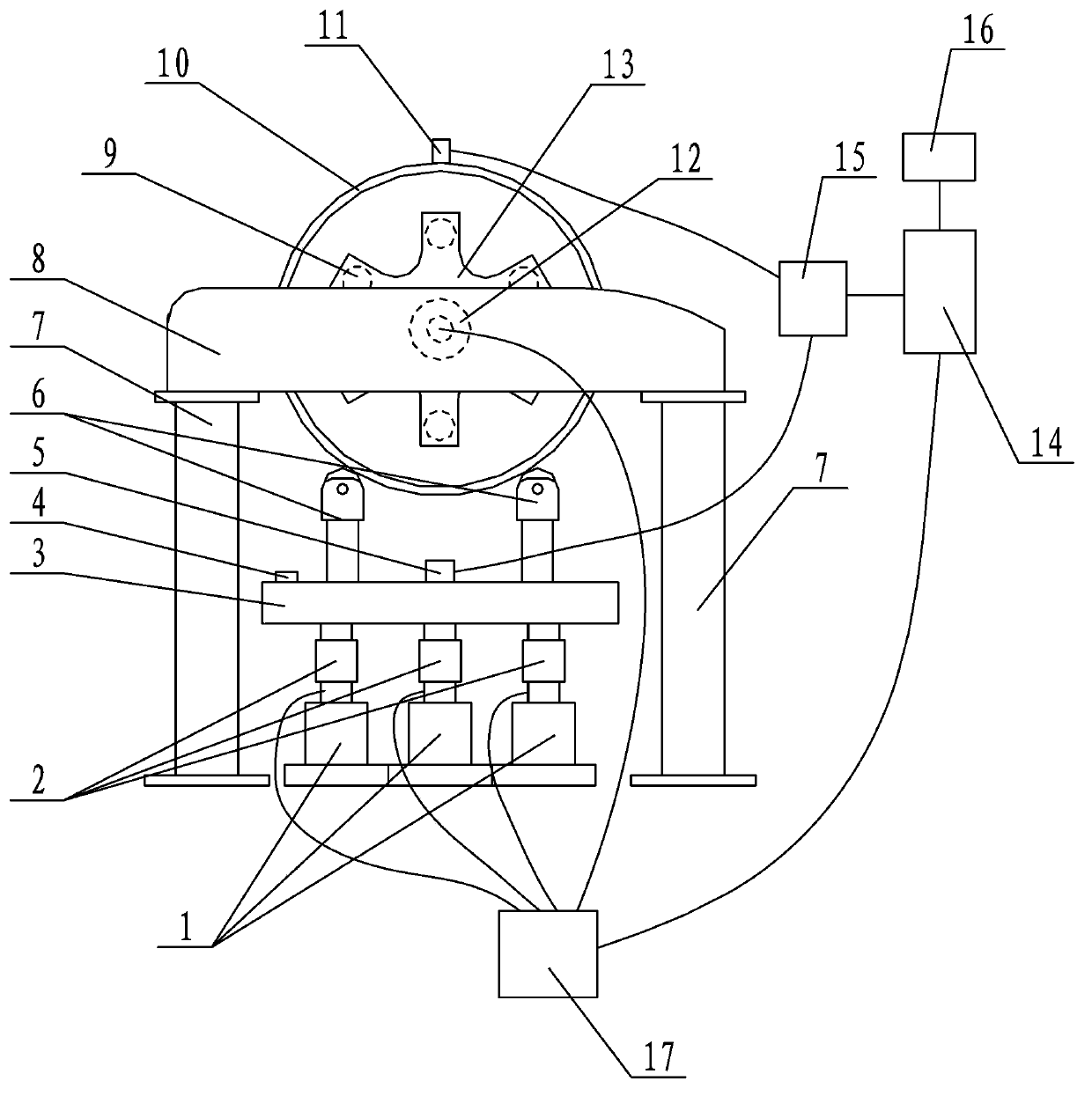

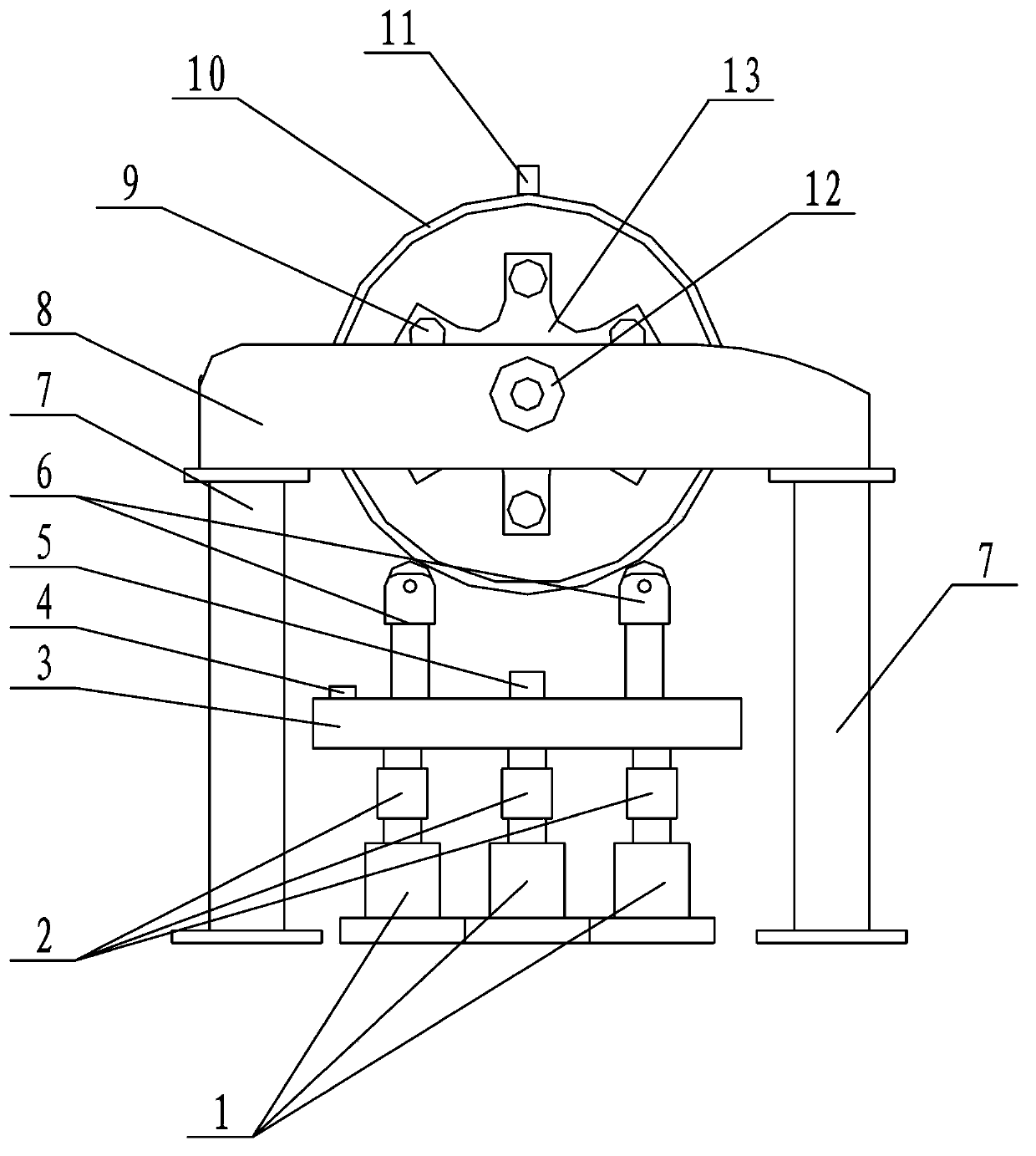

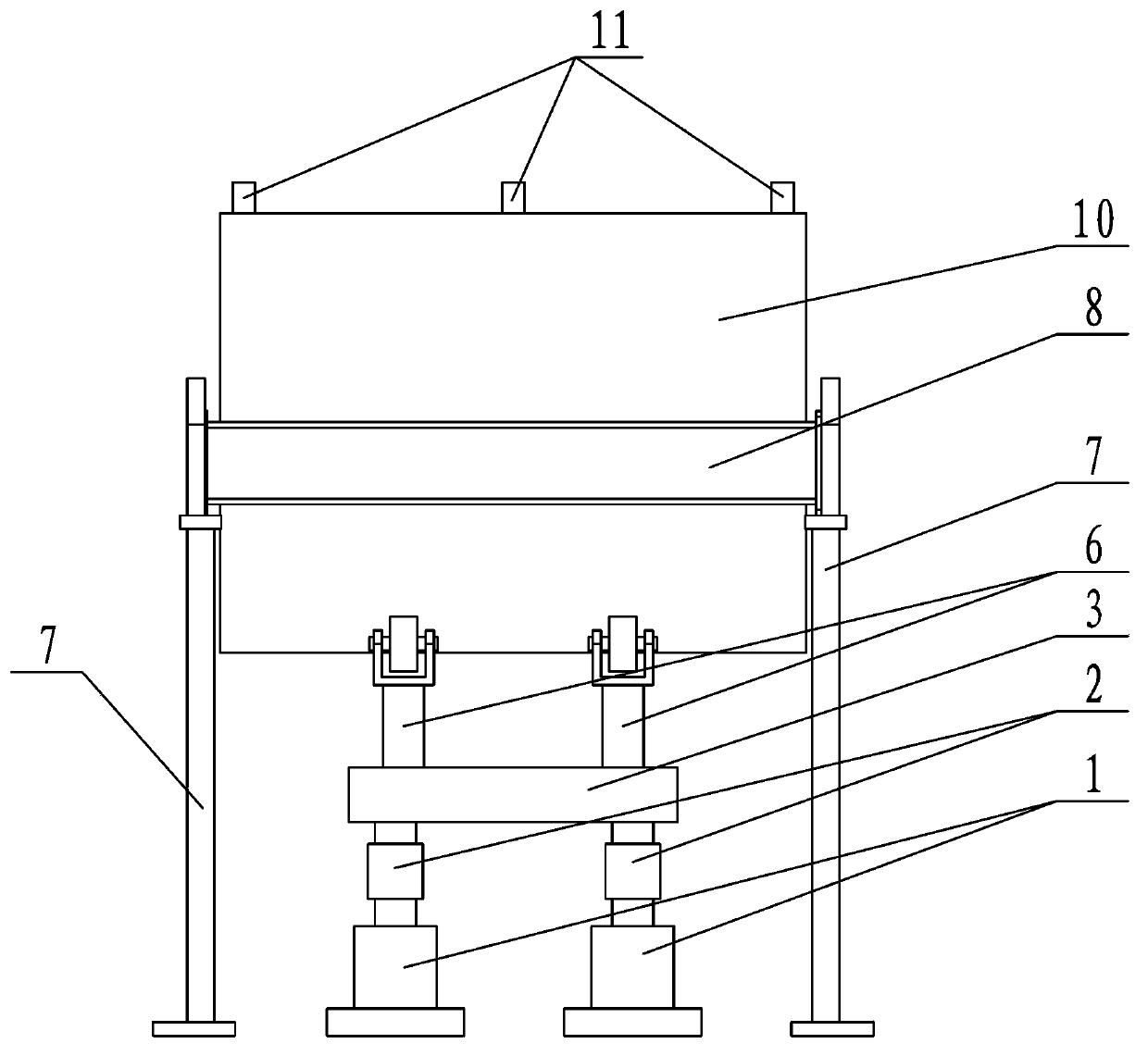

[0048] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown in the test system for the center of mass and amplitude uniformity of the road roller steel wheel of the present invention, the road roller steel wheel 10 is installed on the road roller front frame 8 through a vibrating shaft and is fixedly connected to the road roller front frame 8 by bolts. A vibration motor 12 for driving the vibration shaft to vibrate is installed on the front frame 8 of the road roller, and the output shaft of the vibration motor 12 is connected with the vibration shaft; the present invention includes a steel wheel centroid test system, a steel wheel amplitude uniformity test system and a hydraulic system 17, and a control system for analyzing and processing the test data of the steel wheel center of mass test system and the steel wheel amplitude uniformity test system and for controlling the hydraulic system 17; the steel wheel center of mass test system includes three leveling oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com