Wet type raw material feeding device and method for feeding multiple raw materials

A technology for adding devices and raw materials, applied in the field of powder activated carbon, nutrient salt and microbial strain dosing devices, can solve the problems of dust running out, dust pollution, pollution, etc., and achieve the effect of increasing the utilization rate and improving the mixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

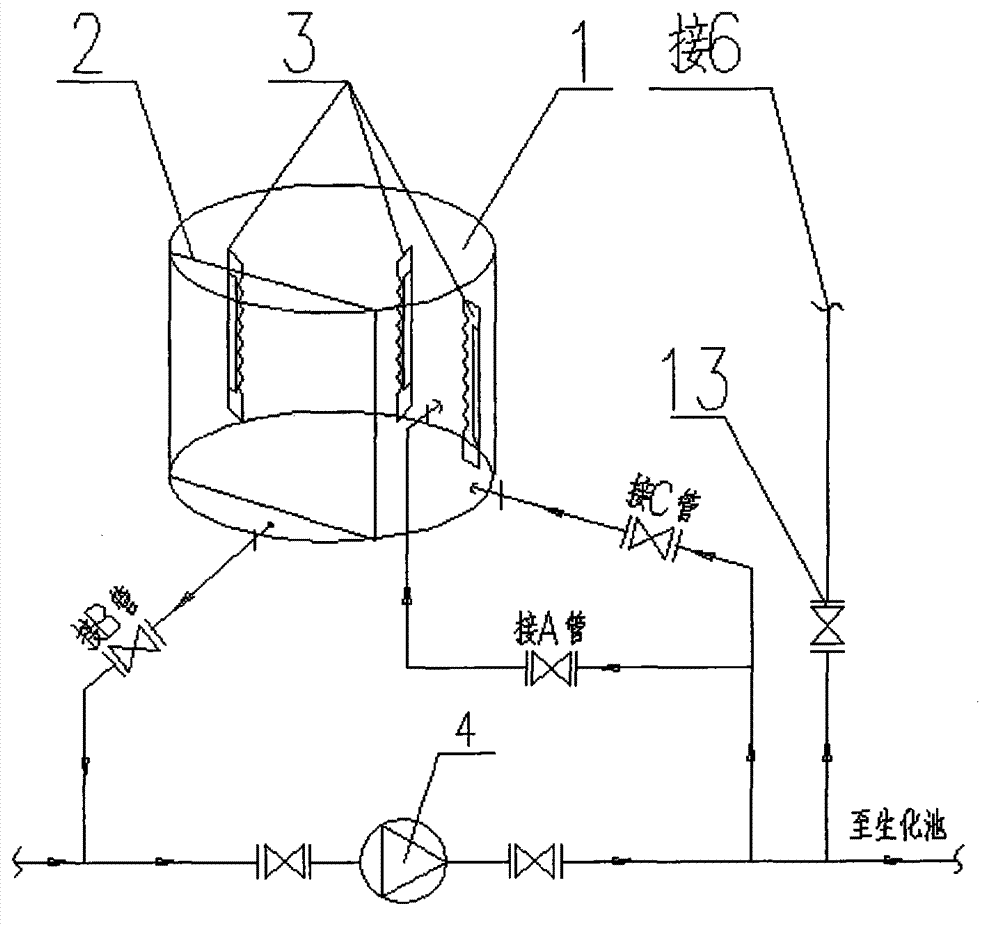

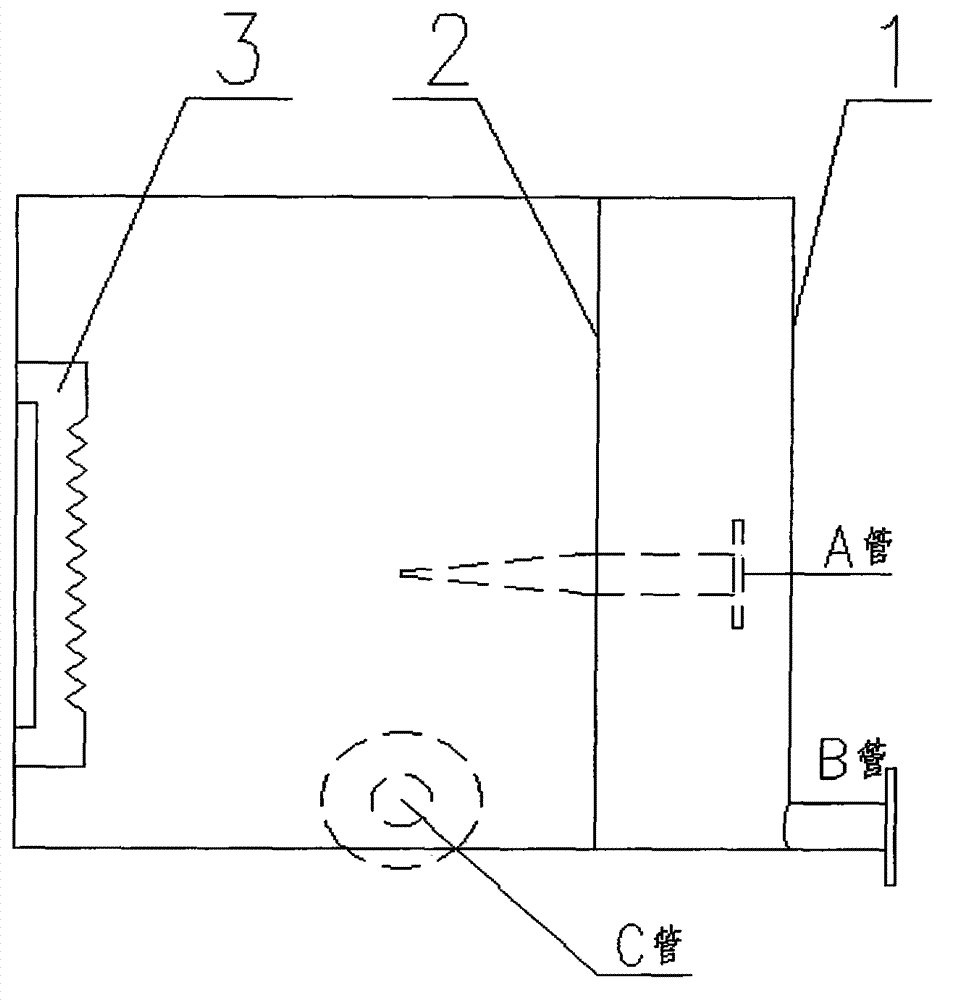

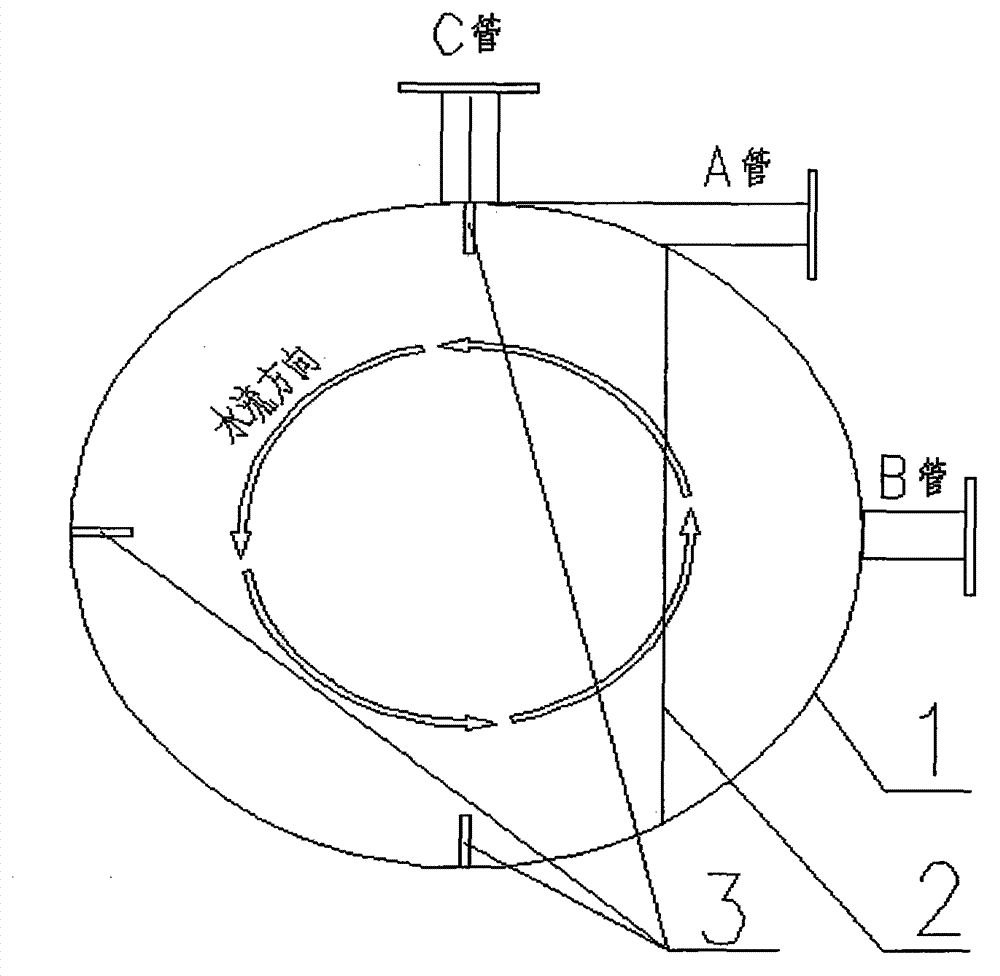

[0033] Such as figure 1 , figure 2 , image 3 As shown, a raw material wet dosing device includes a tank body 1, an orifice plate 2, a baffle plate 3, a water pump 4 and corresponding supporting pipelines. The two sides are vertically welded on the inner wall of the tank body 1, and the cylindrical tank body 1 is divided into two parts, a large part and a small part. 3 three, the bottom of the tank 1 mixing area is connected to the C pipe, the middle of the tank 1 mixing area is connected to the A pipe in the tangential direction, the bottom of the tank 1 discharge area is connected to the B pipe, the B pipe is connected to the water pump 4 inlet pipe, A pipe, C pipe Connect the water pump 4 outlet pipe.

[0034] The raw material wet-type dosing device is installed on one side of the water inlet pump of the biochemical pool, wherein the 4 inlet pipes of the water pump are connected to the production storage tank or the domestic sewage storage tank, and the 4 outlet pipes ...

Embodiment 2

[0044] The method of adding flour, glucose, phosphorus salt, nitrifying bacteria culture accelerator, and microbial strains by using the above-mentioned raw material wet feeding device is characterized in that:

[0045] a) The first step is to open the inlet and outlet valves of the water pump 4, open the inlet valves of the A pipe and the C pipe, and turn on the water pump 4. The domestic sewage is pumped from the domestic sewage pool into the biochemical pool, and a small part of the domestic sewage is diverted into the tank body 1. , the water in pipe C flows in from the bottom of the tank body 1, the water in pipe A flows in tangentially from the middle of the tank body 1, when the domestic sewage is about to fill the tank body 1, open the outlet valve of pipe B, and the outlet water goes to the inlet pipe of water pump 4, adjust the inlet , The outlet valve ensures the balance of the water entering and exiting the tank 1;

[0046] b) The second step is to evenly pour the ...

Embodiment 3

[0053] a) The first step is to open the inlet and outlet valves of water pump 4, open the inlet valves of pipe A and pipe C, and turn on the water pump 4. Most of the domestic sewage is pumped into the biochemical pool, and a small part is pumped into tank 1, and water from pipe C flows into the tank. At the bottom of 1, the water flow from pipe A tangentially enters the middle of tank 1. When the domestic sewage is about to fill the tank 1, open the outlet valve of pipe B, and the outlet water goes to the inlet pipe of water pump 4. Adjust the inlet and outlet valves to ensure the balance of water in and out of tank 1;

[0054] b) The second step is to evenly pour the raw material nitrifying bacteria culture accelerator or microorganisms into the tank body 1 mixing zone, the water flow in pipe A tangentially drives the nitrogen fertilizer to form a swirl in the water and disperses and dissolves, and the water flow in pipe C drives the nitrifying bacteria culture accelerator upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com