Glass fiber-reinforced PE (Poly Ethylene) compound material and preparation method and application thereof

A composite material, glass fiber technology, applied in mechanical equipment, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of easy bending, expansion, expansion, insufficient strength of PE pipes, deformation of water pipes, etc., and achieve impact resistance. Strong, solve the effect of bending and stretching in case of hot water, and preventing the pipe from sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical characteristics of the present invention will be further elaborated below in conjunction with specific embodiments.

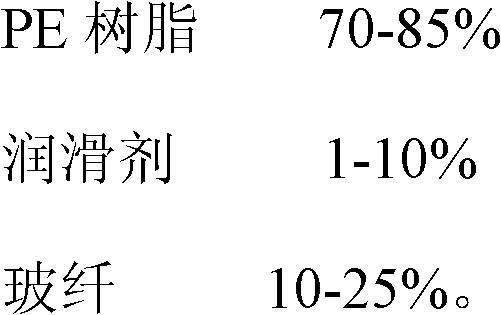

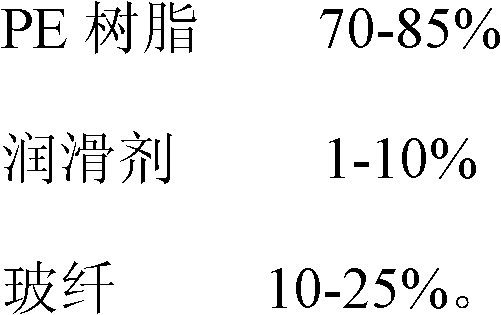

[0018] Materials used in the present invention are as follows:

[0019] HDPE Xinjiang Dushanzi grade 6070;

[0020] OP wax Shanghai Jiazhuo Chemical;

[0021] Ethylene acrylic acid copolymer American Honeywell company brand 540A;

[0022] Glass fiber Produced by Jushi Group, brand ER-988.

[0023] Weigh the PE resin and lubricant according to the proportion, mix them at a high speed with a high-speed mixer, and then melt and extrude them through a twin-screw extruder. The glass fiber is added from the side glass fiber feeding port, and then cooled and granulated to obtain the combination. material, the process temperature is 240-260°C.

[0024] The formula of embodiment 1~4

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com