Phenolic curing agent for high-temperature-resistant and high-hardness epoxy resin powder coating and preparation method

A technology of epoxy resin powder and phenolic curing agent, which is applied in the field of powder coatings, can solve the problems of high temperature resistance, low end group activity, and low molecular branching degree, and achieve high temperature resistance, excellent gasoline performance, and gasoline resistance Excellent performance and high activity of terminal hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

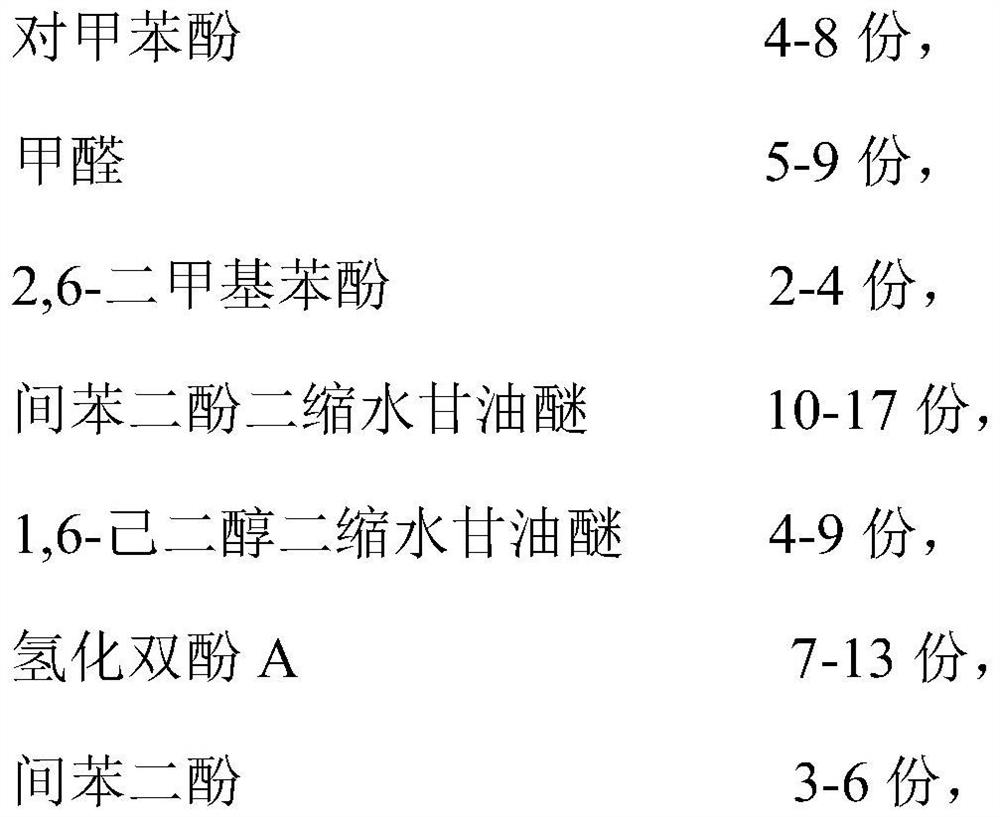

[0037] A preparation method of a high temperature resistant, high hardness epoxy resin powder coating phenolic curing agent, the composition of its raw materials includes in molar fractions:

[0038]

[0039] The catalyst is triphenylphosphine in a molar amount of 0.1% of the molar amount of p-cresol; and

[0040] pH regulator.

[0041] The hydroxyl equivalent of the obtained phenolic curing agent is 471g / mol, and the softening point is 84°C

Embodiment 2

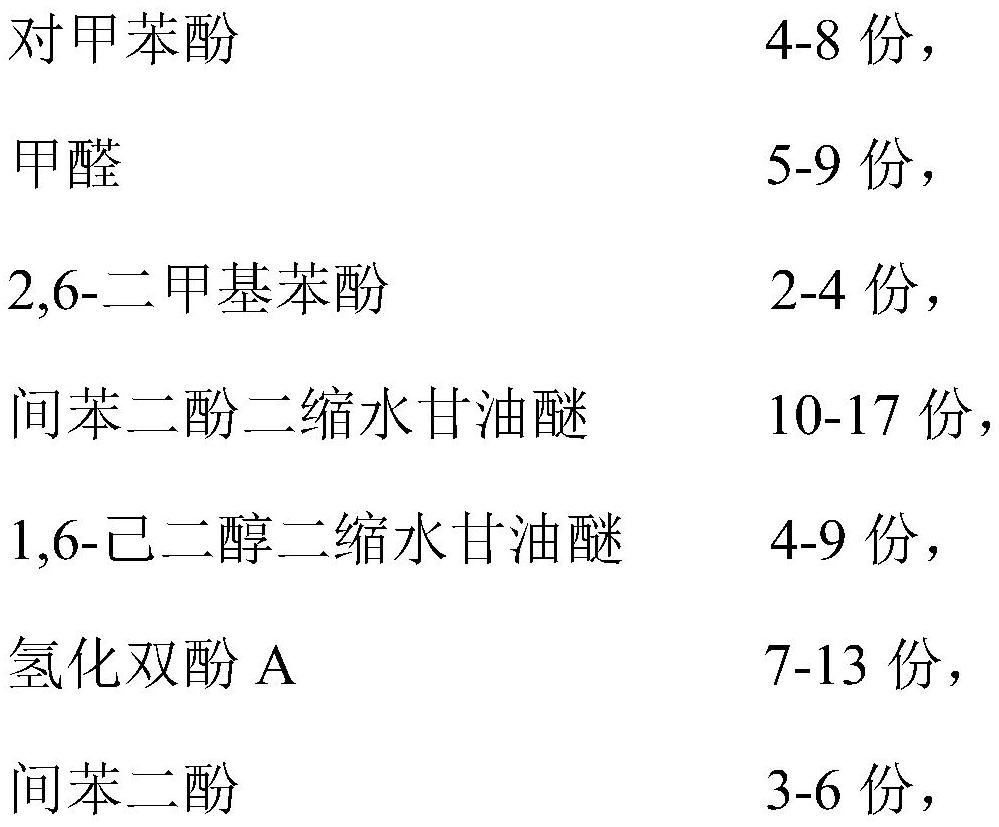

[0043] A preparation method of a high temperature resistant, high hardness epoxy resin powder coating phenolic curing agent, the composition of its raw materials includes in molar fractions:

[0044]

[0045] The catalyst is triphenylphosphine, and its molar dosage is 0.05% of p-cresol molar dosage.

[0046] The hydroxyl equivalent weight of the obtained phenolic curing agent is 458g / mol, and the softening point is 90°C.

Embodiment 3

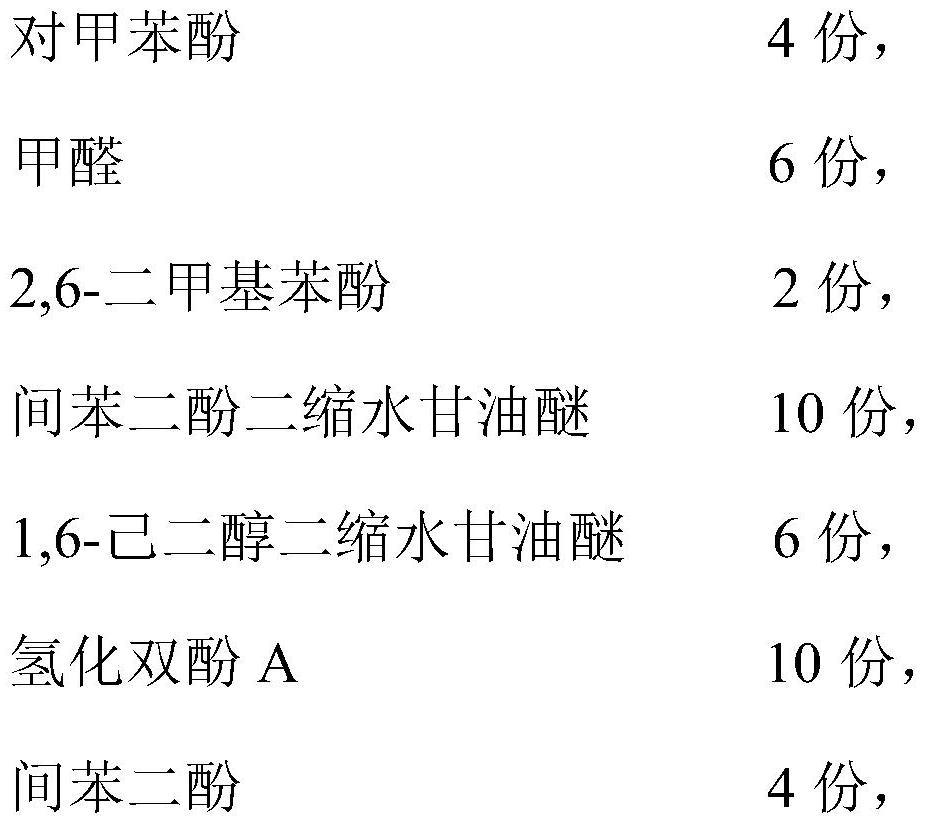

[0048] A preparation method of a high temperature resistant, high hardness epoxy resin powder coating phenolic curing agent, the composition of its raw materials includes in molar fractions:

[0049]

[0050] The catalyst is triphenylphosphine, and its molar dosage is 0.08% of p-cresol molar dosage.

[0051] The hydroxyl equivalent weight of the obtained phenolic curing agent was 493g / mol, and the softening point was 86°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com