Impact-resistant and wear-resistant adhesive coating and preparation method thereof

An impact-resistant, wear-resistant and adhesive technology, applied in the field of wear-resistant adhesives, can solve the problems of reduced material temperature resistance, slow curing speed, unable to completely avoid bisphenol A crystallization, etc., so as to improve impact toughness and maintain resistance. The effect of temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

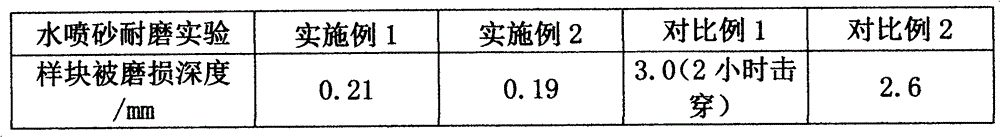

Examples

Embodiment 1

[0032] Production process of component A: According to the ratio of parts by mass, pre-mix 40 parts of bisphenol A epoxy resin, 40 parts of bisphenol F epoxy resin, and 1 part of silane coupling agent in a high-speed mixer according to the proportion, and stir for about 20min; then add 15 parts of aramid pulp, 300 parts of silicon carbide, 50 parts of alumina, and 2 parts of silicon dioxide according to the proportion, stir in a double planetary high-viscosity mixer, keep the vacuum at -0.08~-0.09Mpa, stir About 30min. After the stirring is stopped, wait for the mixture to cool down to the ambient temperature naturally, and discharge the material for filling. At this time, the form of component A is paste.

[0033] Production process of component B: according to the ratio of parts by mass, pre-mix 15 parts of polyamine, 2 parts of polythiol, 5 parts of silane coupling agent, and 2 parts of curing accelerator in a high-speed mixer according to the proportion, and stir for abou...

Embodiment 2

[0036] Production process of component A: According to the ratio of parts by mass, pre-mix 40 parts of bisphenol A epoxy resin, 40 parts of bisphenol F epoxy resin, and 1 part of silane coupling agent in a high-speed mixer according to the proportion, and stir for about 20 minutes; then add 2 parts of aramid pulp, 350 parts of silicon carbide, and 60 parts of alumina according to the proportion, and stir in a double planetary high-viscosity mixer, keeping the vacuum at -0.08~-0.09Mpa, and stirring for about 30 minutes. After the stirring is stopped, wait for the mixture to cool down to the ambient temperature naturally, and discharge the material for filling. At this time, the form of component A is paste.

[0037] Production process of component B: according to the ratio of parts by mass, pre-mix 15 parts of the above-mentioned polyamine, 2 parts of polythiol, 3 parts of silane coupling agent, and 1 part of curing accelerator in a high-speed mixer according to the proportion,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com