Cu-Ni-Nb ternary alloy film with low resistivity and high chemical inertia and preparation process thereof

A cu-ni-nb, chemically inert technology, applied in the field of new materials, can solve the problems of electronic device damage, obstruction, lack of theoretical guidance, etc., and achieve the effect of eliminating electron scattering effect and reducing electron scattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions.

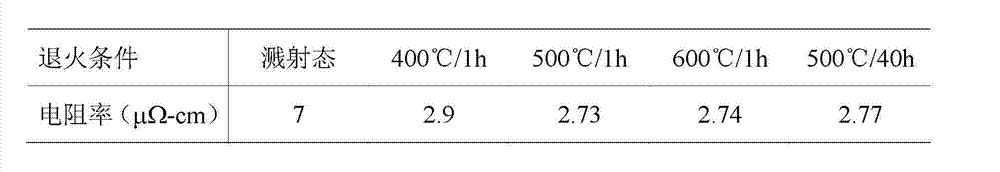

[0024] The following composition is Cu 99.68 Ni 0.29 Nb 0.03 (atomic percent) [Cu 99.69 Ni 0.27 Nb 0.04 (weight percent)] as an example to describe the preparation process steps:

[0025] The first step, preparation of combined alloy target

[0026] Material preparation: According to the Ni and Nb components in the design composition, weigh the value of each component and wait for use. The purity of Ni and Nb metal raw materials is required to be above 99.99%;

[0027] Melting of Ni-Nb alloy ingots: put the metal mixture in the water-cooled copper crucible of the electric arc melting furnace, use the non-consumable arc melting method to melt under the protection of argon, and first vacuumize to 10 -2 Pa, then filled with argon until the pressure is 0.03±0.01MPa, the control range of melting current density is 150±10A / cm 2 , after melting, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com