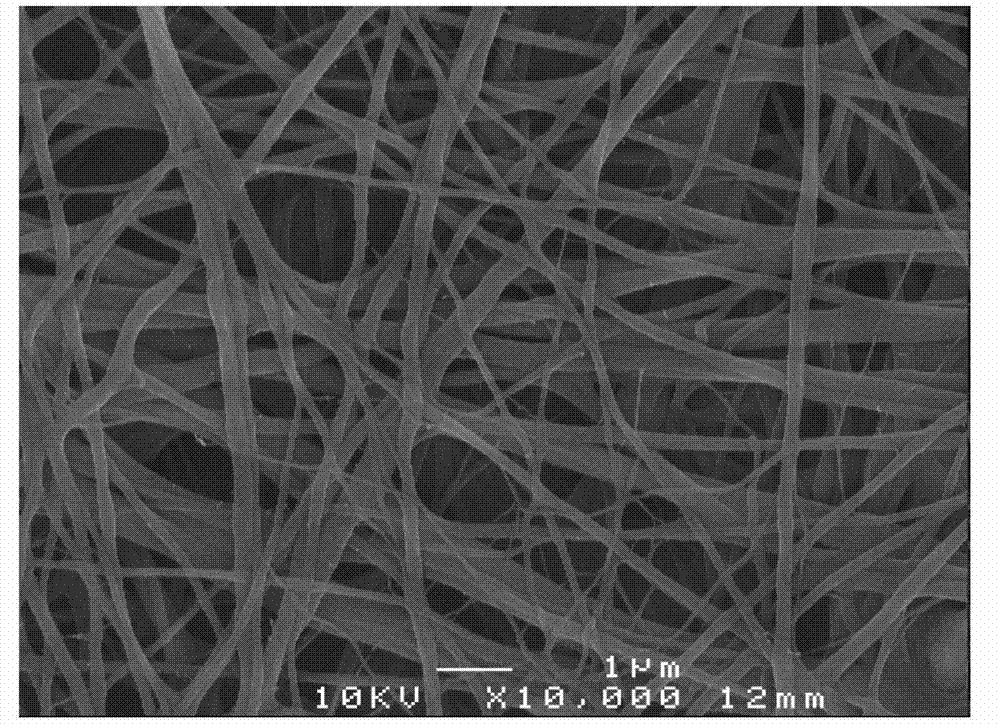

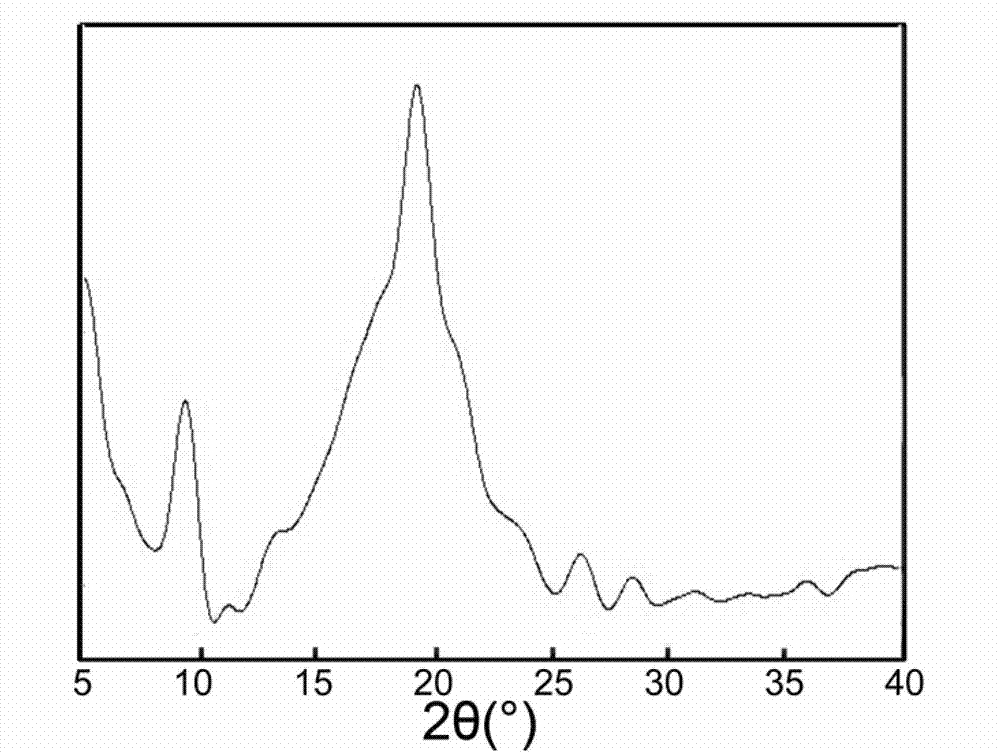

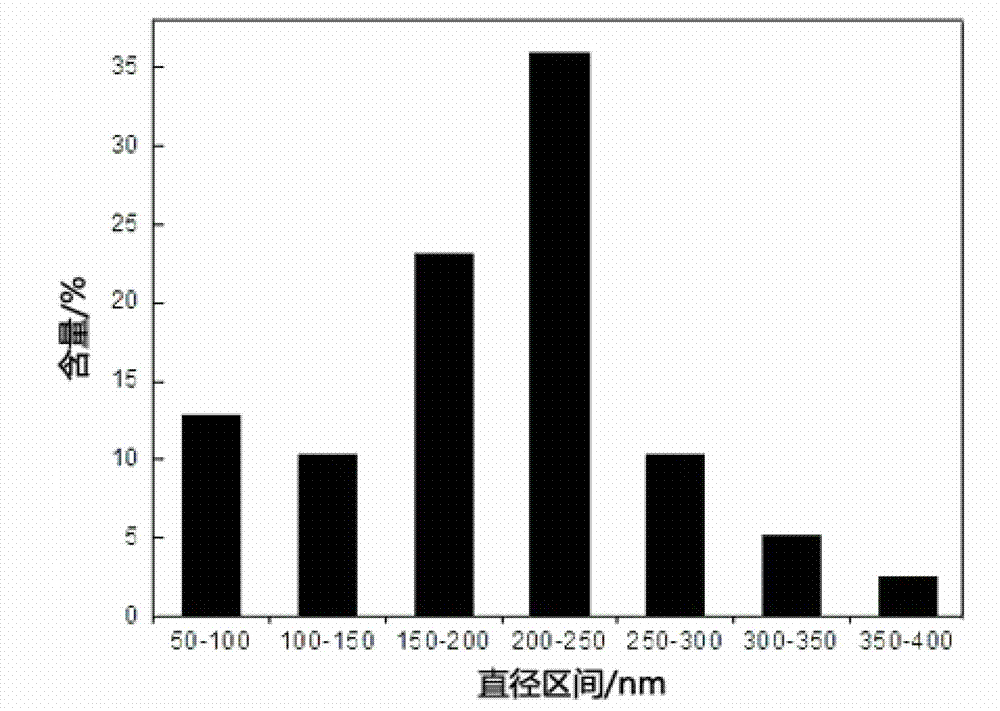

Method for preparing chitin nano filaments

A technology of nanofibrils and chitin, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of short chitin nanofibrils and cannot meet market demands, and achieves simple preparation process, environmental protection and green cost, and fibrils. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: the preparation method of a kind of chitin nanofibril provided in this embodiment, specifically is finished according to the following steps:

[0037] 1. Drying and pulverizing the biological raw material to obtain biological raw material powder; or directly pulverizing to obtain biological raw material powder, wherein the biological raw material is the exoskeleton of a crustacean containing chitin;

[0038] 2. Add lye to the biological raw material powder obtained in step 1 for processing, and obtain the biological raw material powder with partial protein removal;

[0039] 3. Add hydrochloric acid solution to the biological raw material powder obtained in step 2 to obtain demineralized salt and partial protein biological raw material powder;

[0040] Four, add lye to the biological raw material powder of demineralized salt and part protein obtained in step 3 and carry out further processing, obtain the biological raw material powder of deminera...

specific Embodiment approach 2

[0053] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the biological raw material described in step 1 is shrimp shell or crab shell, and the particle size of the biological raw material powder is 50 mesh to 70 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0054] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying described in step 1 is drying at 50° C. to 105° C. for 10 minutes to 180 minutes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com