Float type optical fiber Bragg grating density sensor of Pb-Sn (plumbum-stannum) molten alloy

A molten alloy, float type technology, applied in the direction of material analysis by measuring buoyancy, can solve the problems of strict requirements on software and hardware environment and measurement methods, difficult to achieve portable real-time measurement, etc., and achieve strong anti-interference ability and excellent linearity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The specific parameters in actual production are:

[0043] 1. The inside of the float is filled with lead so that its density is greater than that of the molten alloy. The dimensions are: the radius of the bottom surface is 50mm, and the height is 50mm;

[0044] 2. The size of the equal-strength cantilever beam is: the length is 120 mm, the width of the fixed end is 30 mm, and the thickness is 3 mm;

[0045] 3. The material of the equal strength cantilever beam is 45# steel, and the Young’s modulus is 200 GPa;

[0046] 4. The effective length of sensing optical fiber for high temperature measurement is 120mm;

[0047] 5. The steel bar equal arm lever is made of high rigidity stainless steel material. The length is 120mm;

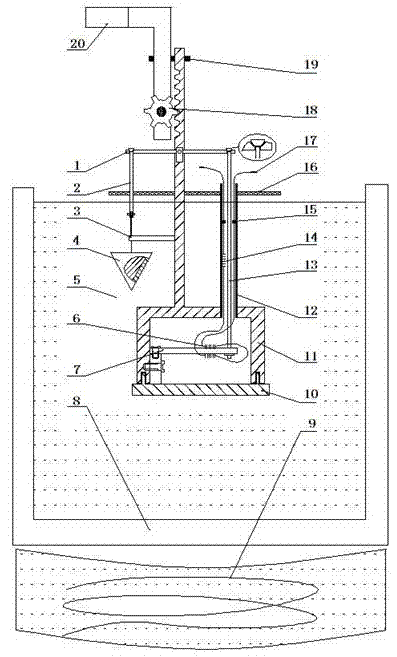

[0048] 6. Press figure 1 Experiment with the configuration shown;

[0049] 7. Obtain the Bragg wavelength of the sensing grating with a fiber grating analyzer;

[0050] 8. Theoretical results show that when the theoretical wavelength of the sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com