Processing method of ultrafine green tea powder

A processing method and technology of green tea powder, which is applied in the direction of tea treatment before extraction, can solve the problems of loss of chlorophyll and other nutrients, slag feeling at the entrance, and large tea powder particles, so as to maintain the quality of color, fragrance, increase added value, and retain high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention will be further described,

[0017] The specific implementation method and steps of the invention

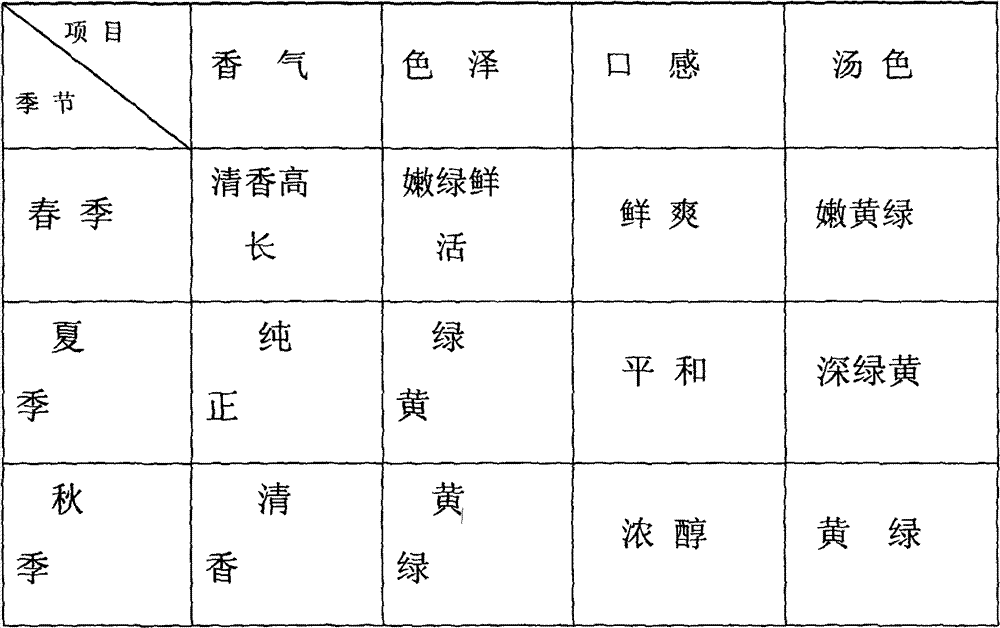

[0018] Through the comparison of fresh leaves of different varieties, different seasons, and different tenderness, select fresh spring and autumn tea leaves suitable for processing ultra-fine green tea powder as raw materials, and retain the chlorophyll of ultra-fine green tea powder to the maximum during the processing process to achieve fragrance and taste. Strong alcohol, yellow-green color.

[0019] Processing method of the present invention comprises the following steps:

[0020] Fresh tea leaves: use the summer and autumn tea grown in the same year as raw materials and the leaves of the same tenderness. Fresh and clean are required.

[0021] Finishing: drum-type continuous grinding machine or intermittent drum grinding machine can be used. The pot temperature is 240°C-300°C.

[0022] Cooling: After the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com