Clear tomato juice beverage product for reinforcing lycopene and preparation method

A technology for lycopene and tomato is applied in the field of tomato clear juice beverage products and preparation fields fortified with lycopene, which can solve the problems of unacceptable consumers and achieve the effects of rich tomato flavor and refreshing taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]1) Using 2.0 g of lycopene with a purity of 90% and derived from natural tomatoes, according to the method described in 201010017228.3, prepare lycopene with a cis configuration of more than 45%;

[0042] 2) Weigh 1.0 g of the above lycopene sample, add it to 5.0 g of pre-weighed corn oil preheated to 100°C, and 2 Stir until it dissolves under protection to obtain lycopene oil;

[0043] 3) Add 40 g of Tween 20 / ethanol (Tween 20: ethanol = 2: 1) mixture preheated to 30°C to the lycopene oil, and stir at 150 rpm for 20 minutes to disperse the ingredients evenly;

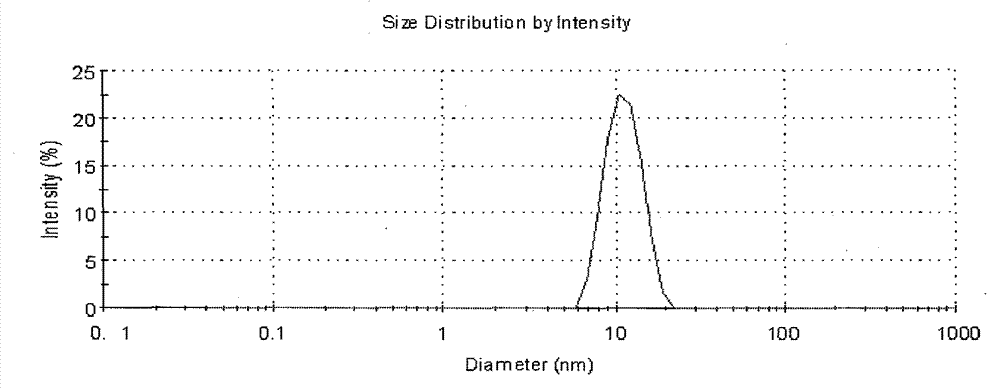

[0044] 4) Add 69g of pure water to the mixture obtained in 3), continue stirring for 10-30 minutes and cool to room temperature; the content of lycopene is 0.6g / 100mL;

[0045] 5) Add 150mL of 40Brix tomato concentrated juice, 1200g of white sugar, 3.0g of steviol glycoside (RA98), 45g of citric acid, 25Kg of purified water into the batching tank and heat to 90°C, then add lycopene content of 0.6g / 100mL Microem...

Embodiment 2

[0048] 1) Using 1.5 g of lycopene with a purity of 95% and derived from microbial fermentation, according to the method described in 201010017228.3, prepare lycopene with a cis configuration accounting for more than 51%;

[0049] 2) Weigh 1.1 g of the above-mentioned lycopene sample, add it to 10 g of pre-weighed caprylic triglyceride preheated to 120 °C, and 2 Stir until it dissolves under protection to obtain lycopene oil;

[0050] 3) Add 110 g of lecithin / 1,3-propanediol (lecithin: 1,3-propanediol=2:1) mixture preheated to 35° C. in lycopene oil, and stir at 300 rpm for 20 minutes to make The ingredients are evenly dispersed;

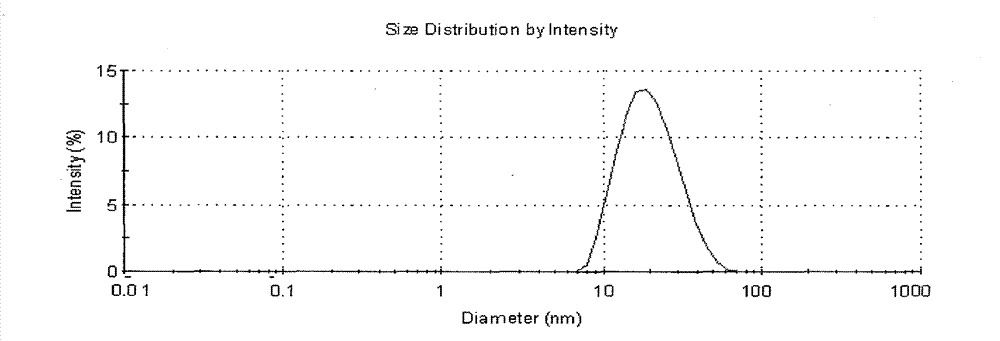

[0051] 4) Add 240g of pure water to the mixture obtained in 3), continue stirring for 10-30 minutes and cool to room temperature; the content of lycopene is 0.3g / 100mL;

[0052] 5) Add 300mL of 28Brix tomato concentrate juice, 2.0g of steviol glycoside (RA98), 2.0g of licorice extract, 25g of citric acid, 20g of malic acid, 25Kg of purified water...

Embodiment 3

[0055] 1) Select 2.0 g of artificially synthesized lycopene with a purity of 90%, and prepare lycopene whose cis configuration accounts for more than 55% according to the method described in 201010017228.3;

[0056] 2) Weigh 1.5g of the above-mentioned lycopene sample and add it to 9.0g of soybean oil / palm oil mixed oil that has been weighed in advance and preheated to 110°C. The mass ratio of soybean oil to palm oil is 3:1. CO 2 Stir until it dissolves under protection to obtain lycopene oil;

[0057] 3) Add 95 g of Tween 40 / glycerin (Tween 40:glycerol=2:1) mixture preheated to 40°C to the lycopene oil, and stir at 200 rpm for 25 minutes to disperse the ingredients evenly;

[0058] 4) Add 250 g of pure water to the mixture obtained in 3), continue stirring for 10-30 minutes and cool to room temperature; the content of lycopene is 0.38 g / 100 mL;

[0059] 5) Add 300mL of 36Brix tomato concentrated juice, g, 1200g of white sugar, 4.0g of licorice extract, 2.0g of monk fruit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com