Polyester resin for household appliances and preparation method thereof

A technology of polyester resin and household appliances, applied in polyester coatings, coatings, powder coatings, etc., can solve the problems of prolonged reaction time, decreased catalytic efficiency, etc., and achieves delaying aging process, prolonging service life, excellent and good leveling and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

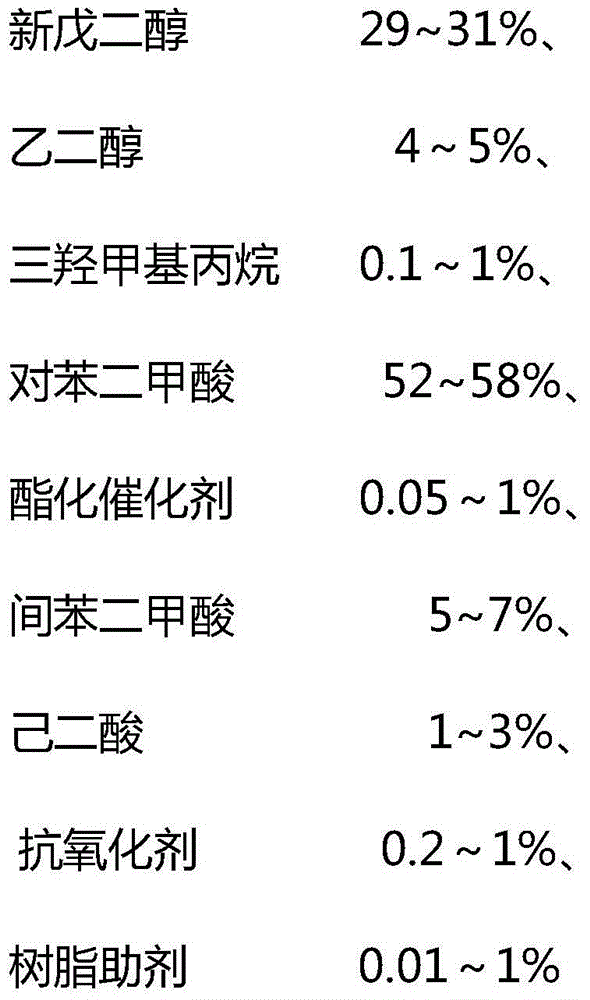

Method used

Image

Examples

Embodiment 1

[0045] Preparation of polyester resin:

[0046] The first stage:

[0047] 353 grams of neopentyl glycol, 3.5 grams of trimethylolpropane, 51 grams of ethylene glycol, 646 grams of terephthalic acid and 0.25 grams of esterification catalyst butylstannoic acid were added to the reactor and mixed;

[0048] Heating the reactor, when the temperature of the packed tower is higher than 101°C, start to pressurize the reactor to 7.3bar;

[0049] After heating the reactor to 250°C, start the depressurization program, and continue to heat the reactor to 260°C, wait until the pressure drops to 0bar, and keep the reactor at 260°C for esterification reaction. When the system is clear and the acid value reaches 10 After -14mg KOH / g (esterification reaction time is 6.0-8.0 hours), enter the second stage;

[0050] second stage:

[0051] 72 grams of isophthalic acid, 24.0 grams of adipic acid, and 0.4 grams of antioxidant pentaerythritol dioctadecyl phosphite were added to the reactor;

[0...

Embodiment 2

[0057] Preparation of polyester resin:

[0058] The first stage:

[0059] 380 grams of neopentyl glycol, 36 grams of ethylene glycol, 640 grams of terephthalic acid and 0.25 grams of esterification catalyst butylstannoic acid are added to the reactor and mixed;

[0060] Heating the reactor, when the temperature of the packed tower is higher than 101°C, start to pressurize the reactor to 7.3bar;

[0061] After heating the reactor to 250°C, start the depressurization program, and at the same time continue to heat the reactor to 260°C, and maintain the reactor at this temperature for esterification reaction. When the system is clear and the acid value reaches 10--14mg KOH / g After (the esterification reaction time is 6.5-8.5 hours), enter the second stage;

[0062] second stage:

[0063] 48 grams of isophthalic acid, 45 grams of adipic acid, and 0.4 grams of antioxidant pentaerythritol dioctadecyl phosphite were added to the reactor;

[0064] After heating the reactor to 250°C...

Embodiment 3

[0069] Preparation of polyester resin:

[0070] The first stage:

[0071] 342 grams of neopentyl glycol, 50 grams of ethylene glycol, 12 grams of trimethylolpropane, 630 grams of terephthalic acid, 10.5 grams of isophthalic acid and 0.25 grams of esterification catalyst butylstannoic acid were added to the reactor and mixed;

[0072] Heating the reactor, when the temperature of the packed tower is higher than 101°C, start to pressurize the reactor to 7.3bar;

[0073] After heating the reactor to 245°C, start the depressurization program, and continue to heat the reactor to 260°C. When the pressure drops to 0bar, keep the reactor at this temperature for esterification reaction. When the system is clear and the acid value reaches After 10.0-14.0mg KOH / g (esterification reaction time is 6.5-8.0 hours), enter the second stage;

[0074] second stage:

[0075] 40.0 grams of isophthalic acid, 60 grams of adipic acid, and 0.4 grams of antioxidant pentaerythritol dioctadecyl phosphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com