Rock wool composite thermal insulation plate integrated with main body structure concrete

A technology of composite thermal insulation and main structure, applied in thermal insulation, building components, chemical instruments and methods, etc., can solve the problems of different life spans between thermal insulation and structures, low thermal insulation and fire protection, cracking, etc., to prevent environmental pollution and occupational diseases, and reduce construction costs. Cost, the effect of improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

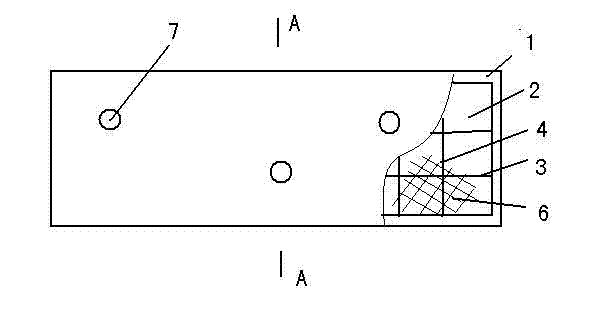

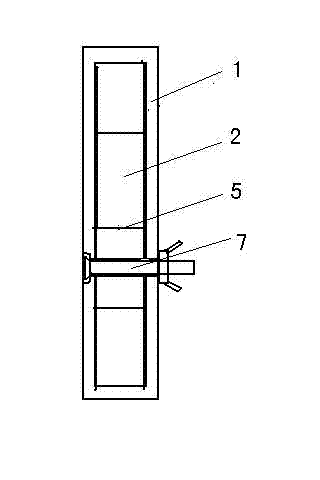

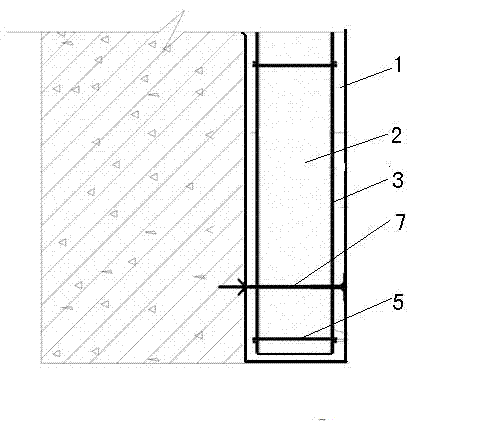

[0018] As shown in the figure: a rock wool composite thermal insulation board integrated with the main structure concrete, including thermal insulation mortar shell 1, rock wool board 2, longitudinal steel wire 3, and transverse steel wire 4, the thickness of the thermal insulation mortar shell layer is not less than 10mm The insulation mortar is composed of cement, fly ash, lightweight aggregate and rubber powder. The weight percentage of each component is cement 15%-30%, fly ash 55%-70%, light aggregate 10%-15%, Rubber powder 1%-3%, lightweight aggregate is slag with a particle size of 5-80 mesh; the thickness of the rock wool board 2 is not less than 70mm, the heat transfer coefficient is not greater than 0.04w / (m.k), and the diameter of the steel wire is not greater than 5 mm , galvanized steel wire or polymer material of equal strength, rock wool board 2 is double-sided with longitudinal steel wire 3 and transverse steel wire 4, the distance between longitudinal steel wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com