High-chlorine biomass and coal co-utilizing system with low-chlorine-corrosion and low-mercury discharge and method

A biomass and chlorine corrosion technology, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of environmental damage, uncleanness, non-renewable coal, etc., and achieve the effect of reducing Hg emission and reducing heat exchange area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

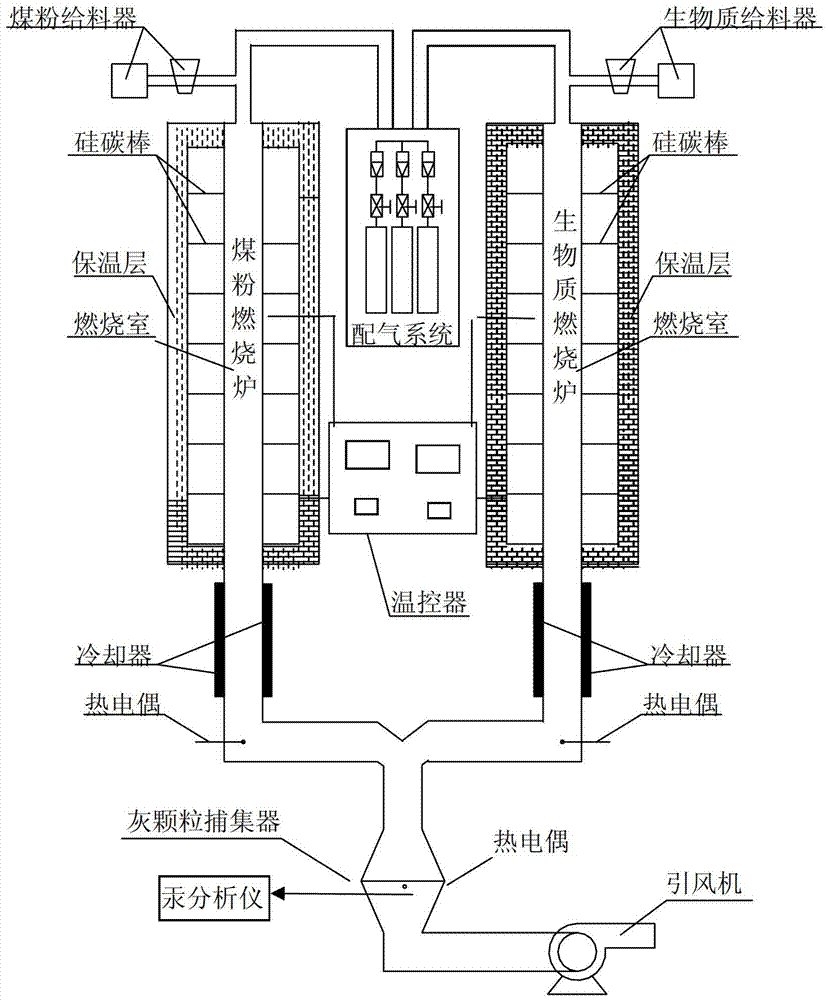

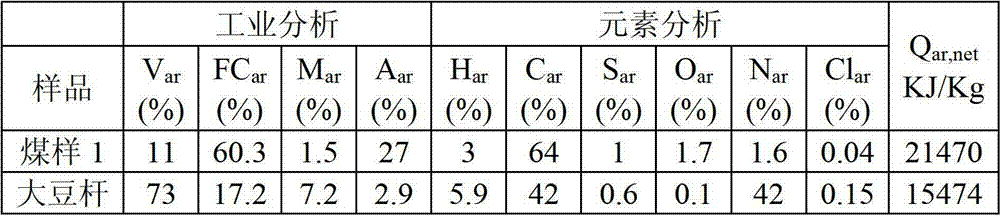

[0047] EXAMPLES Tests are performed in such figure 2 The test system shown is carried out. This experiment is mainly to verify that the Cl-containing flue gas produced by the combustion of high-Cl biomass contributes to the Hg concentration in the coal-fired flue gas. 0 Oxidation and granulation of coal-fired flue gas reduce the emission of elemental Hg in various forms of Hg. In the system, the air preheater and the flue gas are not arranged in the circulating flue, but the cooler is arranged to adjust the flue gas temperature before the biomass and pulverized coal flue gas are mixed, so as to meet the conditions set by the system of the present invention. The coal sample 1 used in Example 1 and the elemental analysis and industrial analysis of the biomass are shown in Table 1. Before the experiment, the two parallel tube furnaces were heated to 1100°C by the temperature control system, and the soybean stalks were ground into a powder passing through a 200-mesh sieve. The b...

Embodiment 2

[0051] The experimental method and experimental process of Example 2 are the same as in Example 1, and the biomass components used are the same. The difference is that Example 2 selects coal sample 2. The industrial analysis and elemental analysis of coal sample 2 are shown in Table 2. The mercury content of coal sample 2 is 212ppb, the powder feeding rate is 400g / min, the excess air coefficient is 1.2, and the combustion air volume provided by the gas distribution system is 2.63m 3 / min, at 150, the Hg in the flue gas was measured by a mercury analyzer 0 22.7ng / m 3 , accounting for 73.6% of the mercury content per unit of raw coal sample 1. The biomass feed rate is 125g / min, the calorific value of biomass fuel accounts for 18.4% of the total calorific value (biomass and pulverized coal), the excess air coefficient is 1.8, and the combustion air volume provided by the gas distribution system is 1.2m 3 / min, the Hg in the mixed flue gas is measured by a mercury analyzer 0 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com