Corn recombinant rice and producing method thereof

A technology for recombining rice and corn, applied in applications, food preparation, food science, etc., can solve problems such as poor quality, achieve compact structure, good viscoelasticity, and improve rehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

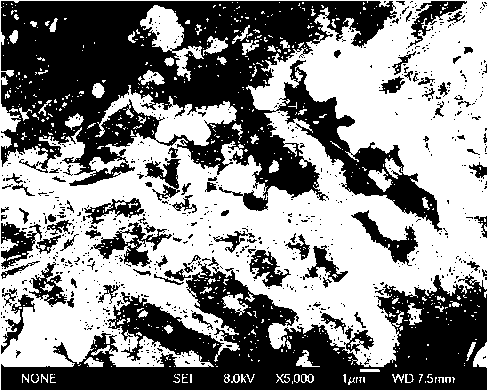

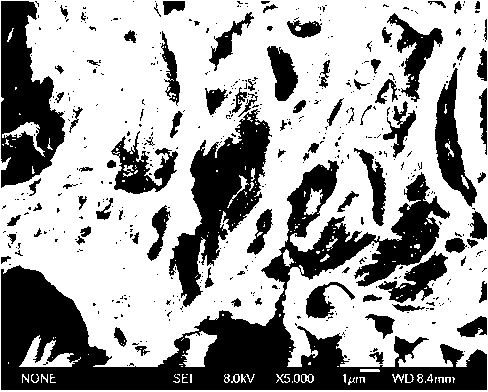

Image

Examples

preparation example Construction

[0025] A. Preparation of Common Corn Flour

[0026] Remove impurities from ordinary corn, peel, degerm, crush, and sieve to obtain ordinary corn flour with a particle size of not less than 40 mesh.

[0027] B. Preparation of Modified Corn Flour

preparation example 1

[0028] Preparation example 1 of enzyme-modified corn flour: Mix common corn flour and water at a mass ratio of 1:2, add 50U / g corn flour with neutral protease, enzymatically hydrolyze and biomodify for 2 hours, then dry in hot air at 60°C for 20 hours , pulverized, and passed through an 80-mesh sieve to obtain enzyme-modified corn flour;

preparation example 2

[0029] Preparation example 2 of enzyme-modified corn flour: Mix ordinary corn flour and water at a mass ratio of 1:3.5, add 125U / g corn flour neutral protease, enzymatically hydrolyze and biomodify for 4 hours, then dry in hot air at 60°C for 20 hours , pulverized, and passed through an 80-mesh sieve to obtain enzyme-modified corn flour;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com