Method for extracting functional ingredients from lucid ganoderma sporocarp

A technology of ganoderma lucidum fruiting body and extraction method, which is applied in the direction of medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, medical formulas, etc., which can solve the problems of consumption of organic solvents, impact on human body and environment, and obtaining of functional ingredients. Low extraction rate and other problems, to achieve the effect of reducing extraction time, facilitating extraction, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 The extraction method of functional components in the ganoderma lucidum fruiting body comprises the following steps:

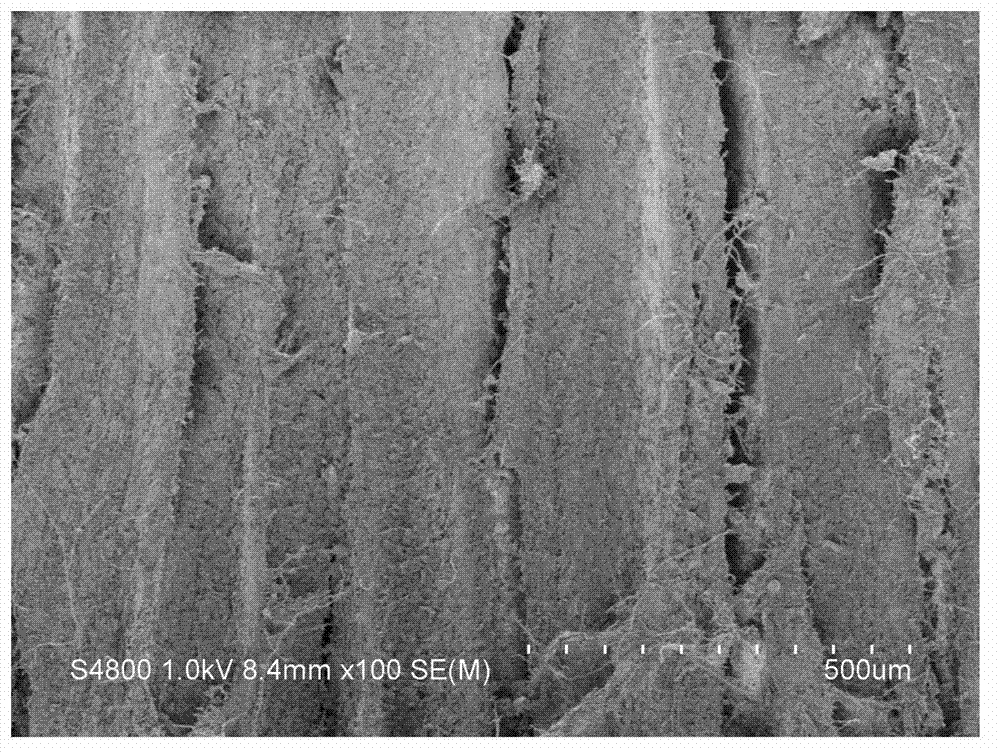

[0028] (1) Dry the fruiting body of Ganoderma lucidum and crush it into debris with a size of 0.5-1.5 cm (for the structure, refer to figure 1 ).

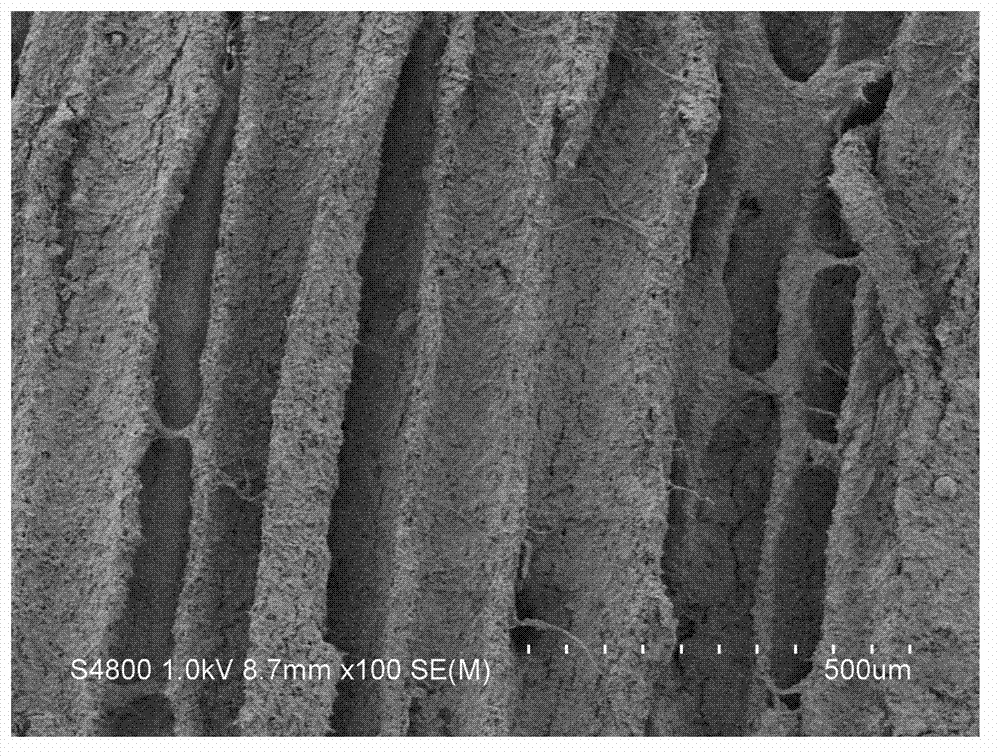

[0029] (2) Treat 400g of Ganoderma lucidum fruiting body after processing in step (1) for 150s under the condition of steam pressure 1.2Mpa to obtain processed Ganoderma lucidum raw material (for structure refer to figure 2 ).

[0030] (3) Take 30 g of ganoderma lucidum raw material obtained in step (2), add water according to the ratio of ganoderma lucidum to water in a ratio of 1:18, extract at 85° C. for 1 hour, filter, and take the filtrate for later use.

[0031] (4) Take the filtrate obtained in step (3) and add absolute ethanol to make the ethanol content in the liquid 75%, let it stand until the precipitation is complete, then filter, and the obtained solid phase vacuum freeze-drying ...

Embodiment 2

[0034] Embodiment 2 The extraction method of functional components in the ganoderma lucidum fruiting body comprises the following steps:

[0035] (1) Dry the fruiting body of Ganoderma lucidum and crush it into debris with a side length of 0.5-1.5 cm.

[0036] (2) Treat 400 g of the ganoderma lucidum fruit bodies treated in the step (1) for 90 seconds under the condition of a steam pressure of 1.8 Mpa to obtain the processed ganoderma lucidum raw material.

[0037] (3) Take 30 g of Ganoderma lucidum raw material obtained in step (2) and add water according to the ratio of Ganoderma lucidum to water in a ratio of 1:18, extract at 85° C. for 1 hour, and filter.

[0038] (4) Take the filtrate obtained in step (3), add absolute ethanol to make the ethanol content in the liquid 75%, let stand until the precipitation is complete, then filter, and filter the obtained solid-phase vacuum freeze-dry to obtain Ganoderma lucidum polysaccharide.

[0039] (5) Take 30 g of Ganoderma lucidum...

Embodiment 3

[0041] Embodiment 3 The extraction method of functional components in the ganoderma lucidum fruiting body comprises the following steps:

[0042] (1) Dry the fruiting body of Ganoderma lucidum and crush it into debris with a side length of 0.5-1.5 cm.

[0043] (2) Treat 400 g of the fruiting bodies of Ganoderma lucidum treated in step (1) for 90 seconds under the condition of steam pressure of 1.2 Mpa to obtain the raw material of Ganoderma lucidum after treatment.

[0044] (3) Take 30 g of Ganoderma lucidum raw material obtained in step (2) and add water according to the ratio of Ganoderma lucidum to water in a ratio of 1:18, extract at 85° C. for 1 hour, and filter.

[0045] (4) Take the filtrate obtained in step (3) and add absolute ethanol to make the ethanol content in the liquid 75%, let it stand until the precipitation is complete, then filter, and the obtained solid phase vacuum freeze-drying obtained by filtration obtains Ganoderma lucidum polysaccharide.

[0046] (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com