Ternary composite catalyst containing platinum, transition metal oxide and graphene and preparation method thereof

A composite catalyst and transition metal technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve long cycle life, high catalytic activity, and mild and controllable process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

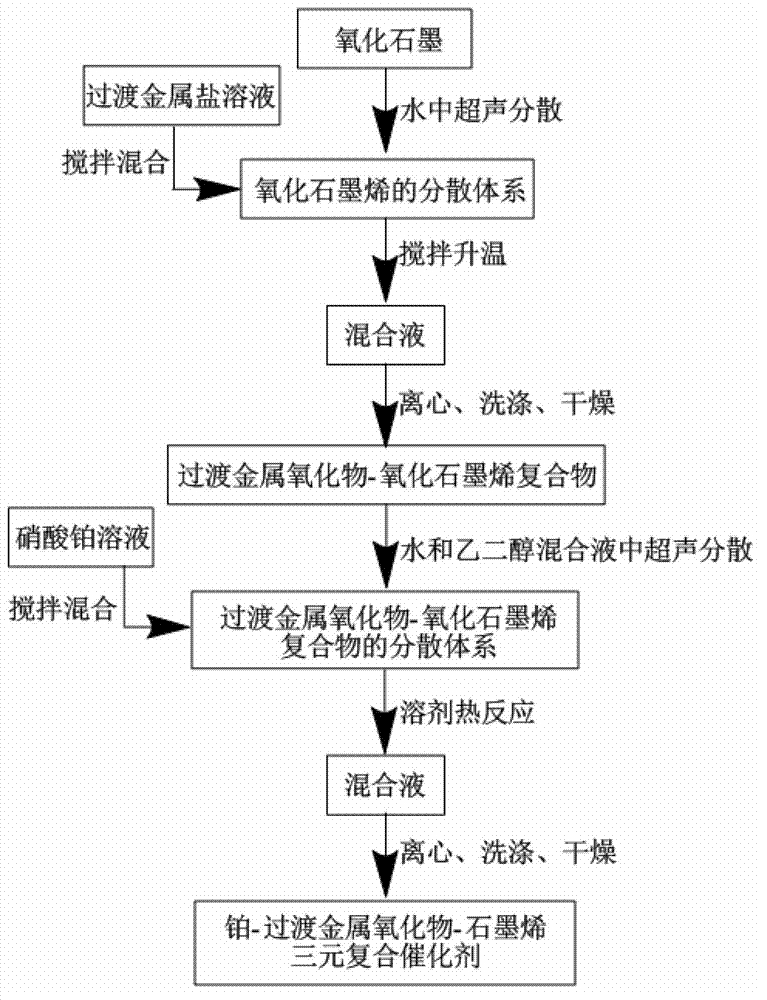

Method used

Image

Examples

Embodiment 1

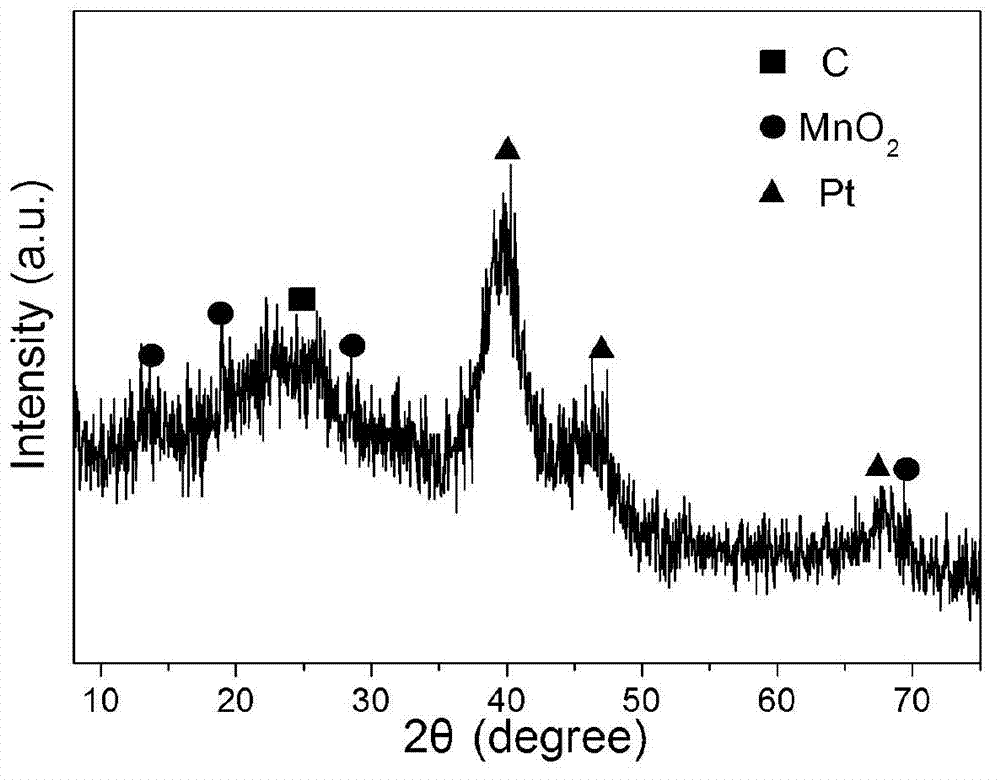

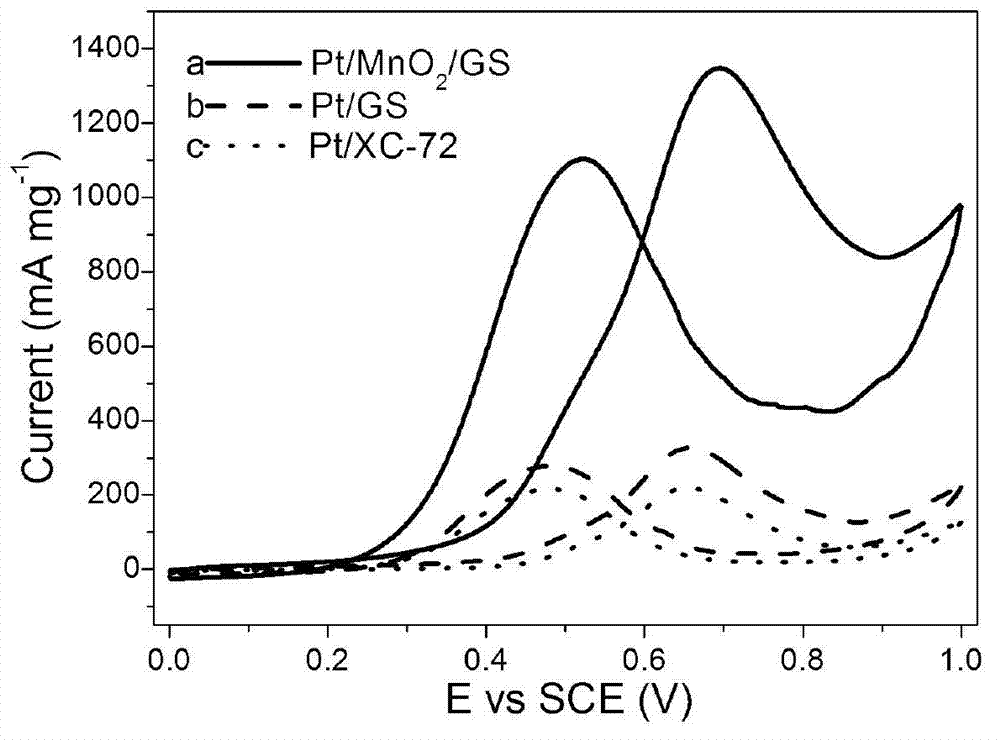

[0030] Example 1: Platinum-manganese dioxide-graphene ternary composite electrode catalyst (manganese dioxide: graphene oxide mass ratio is 1:4.6; platinum: manganese dioxide-graphene oxide binary composite mass ratio is 1 :4)

[0031] (1) Add 400mg of graphite oxide to 600mL of deionized water, and sonicate at 30°C for 2 hours to obtain a dispersed solution of graphene oxide;

[0032] (2) Add 20mL of 0.50mol / L potassium permanganate solution to the system of the first step, and stir and react at 120°C for 12 hours;

[0033] (3) Centrifuge the system in the second step to separate the solid product, wash it with deionized water, and dry it at 60°C to obtain a manganese dioxide-graphene oxide composite;

[0034] (4) Weigh 20 mg of the manganese dioxide-graphene oxide composite obtained in the third step, place it in a mixture of 30 mL deionized water and 50 mL ethylene glycol, and ultrasonicate at 30°C for 2 hours to obtain manganese dioxide- Dispersion solution of graphene o...

Embodiment 2

[0039] Example 2: Platinum-zinc oxide-graphene ternary composite electrode catalyst (the mass ratio of zinc oxide:graphene oxide is 1:10; the mass ratio of platinum:zinc oxide-graphene oxide binary composite is 40:1)

[0040] (1) Add 400mg of graphite oxide to 4000mL of deionized water, and sonicate at 20°C for 1 hour to obtain a dispersed solution of graphene oxide;

[0041] (2) Add 1.00mL of 0.49mol / L zinc acetate solution to the system in the first step, and stir and react at 120°C for 1 hour;

[0042] (3) Centrifuge the system in the second step to separate the solid product, wash it with deionized water, and dry it at 40°C to obtain a zinc oxide-graphene oxide composite;

[0043] (4) Weigh 8.00 mg of the zinc oxide-graphene oxide composite obtained in the third step, place it in a mixture of 10 mL deionized water and 70 mL ethylene glycol, and ultrasonicate at 20°C for 1 hour to obtain zinc oxide-graphene oxide Dispersion solution of graphene composite;

[0044] (5) Add...

Embodiment 3

[0046] Example 3: Platinum-cobalt tetroxide-graphene ternary composite electrode catalyst (mass ratio of cobalt tetroxide:graphene oxide is 10:1; mass ratio of platinum:cobalt tetroxide-graphene oxide binary composite is 1:40)

[0047] (1) Add 400mg of graphite oxide to 40mL of deionized water, and ultrasonicate at 40°C for 3 hours to obtain a dispersed solution of graphene oxide;

[0048] (2) Add 49.83mL of 1.0mol / L cobalt nitrate solution to the system in the first step, and stir and react at 200°C for 72 hours;

[0049] (3) Centrifuge the system in the second step to separate the solid product, wash it with deionized water, and dry it at 80°C to obtain the tricobalt tetroxide-graphene oxide composite;

[0050] (4) Weigh 800 mg of the tricobalt tetroxide-graphene oxide composite obtained in the third step, place it in a mixture of 70 mL deionized water and 10 mL ethylene glycol, and ultrasonicate at 40°C for 3 hours to obtain the tricobalt tetroxide-graphene oxide composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com