Iron oxide/bismuth tungstate composite photocatalyst, preparation method thereof and application thereof

A composite light and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low quantum efficiency, narrow visible light absorption range, and effective use of solar energy. The visible light ratio is not ideal enough to achieve the effect of improving the photocatalytic activity and promoting the application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

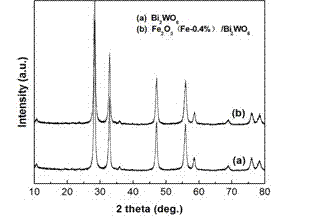

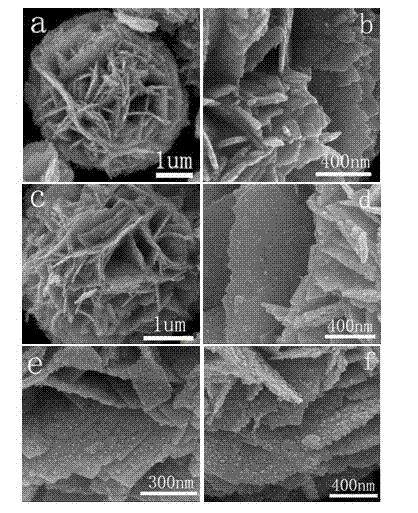

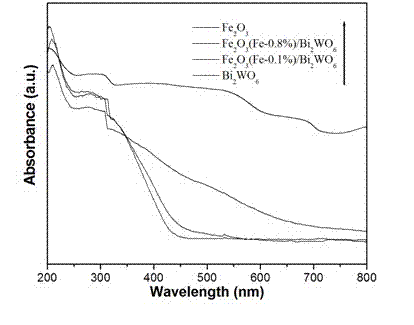

[0054] (1) Flower-like Bi 2 WO 6 Preparation of superstructure: Weigh 0.3881 g (0.8 mmol) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 17 mL of distilled water, and under vigorous magnetic stirring, 0.1319 g (0.4 mmol) of Na 2 WO 4 2H 2 O. After continuing to stir for 30 min, the white suspension was transferred to a 25 mL hydrothermal reactor, and reacted at a constant temperature of 160 °C for 12 h. After natural cooling to room temperature, the product was centrifuged, washed and dried to obtain pale yellow Bi 2 WO 6 Ultrastructured powders (G. Y. Zhang, et. al Mater. Res. Bull. 2012, 47:1919.).

[0055] (2) Fe 2 o 3 Surface modification of nanoparticles, using impregnation-baking technique: weigh 0.1000g of Bi 2 WO 6 Superstructure powder was placed in a 50mL evaporating dish, and 1mL of Fe(NO 3 ) 3 9H 2 O stock solution (1.8 mmol / L), under constant stirring, the mixture was evaporated to dryness under an infrared lamp (temperature 50°C, 10 minutes), and collec...

Embodiment 2

[0057] (1) Flower-like Bi 2 WO 6 Preparation of superstructure: Weigh 0.3881 g (0.8 mmol) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 17 mL of distilled water, and under vigorous magnetic stirring, 0.1319 g (0.4 mmol) of Na 2 WO 4 2H 2 O. After continuing to stir for 30 min, the white suspension was transferred to a 25 mL hydrothermal reactor, and reacted at a constant temperature of 160 °C for 12 h. After natural cooling to room temperature, the product was centrifuged, washed and dried to obtain pale yellow Bi 2 WO 6 Ultrastructured powders (G. Y. Zhang, et. al Mater. Res. Bull. 2012, 47:1919.).

[0058] (2) Fe 2 o 3 Surface modification of nanoparticles, using impregnation-baking technique: weigh 0.1000g of Bi 2 WO 6 Superstructure powder was placed in a 50mL evaporating dish, and 4 mL of Fe(NO 3 ) 3 9H 2 O stock solution (1.8 mmol / L), under constant stirring, the mixture was evaporated to dryness under an infrared lamp (temperature 60°C, 20 minutes), and colle...

Embodiment 3

[0060] (1) Flower-like Bi 2 WO 6 Preparation of superstructure: Weigh 0.3881 g (0.8 mmol) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 17 mL of distilled water, and under vigorous magnetic stirring, 0.1319 g (0.4 mmol) of Na 2 WO 4 2H 2 O. After continuing to stir for 30 min, the white suspension was transferred to a 25 mL hydrothermal reactor, and reacted at a constant temperature of 160 °C for 12 h. After natural cooling to room temperature, the product was centrifuged, washed and dried to obtain pale yellow Bi 2 WO 6 Ultrastructured powders (G. Y. Zhang, et. al Mater. Res. Bull. 2012, 47:1919.).

[0061] (2) Fe 2 o 3 Surface modification of nanoparticles, using impregnation-baking technique: weigh 0.1000g of Bi 2 WO 6 Superstructure powder was placed in a 50mL evaporating dish, and 10mL of Fe(NO 3 ) 3 9H 2 O stock solution (1.8 mmol / L), under constant stirring, the mixture was evaporated to dryness under an infrared lamp (temperature 70°C, 25 minutes), and colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com