Multi-layer plastic composite isolating sheet and production process thereof

A barrier material and sheet technology, applied in the direction of layered products, synthetic resin layered products, lamination, etc., can solve the problems of high price, high cost, complicated equipment, etc., and achieve low cost, both molding performance and barrier performance , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

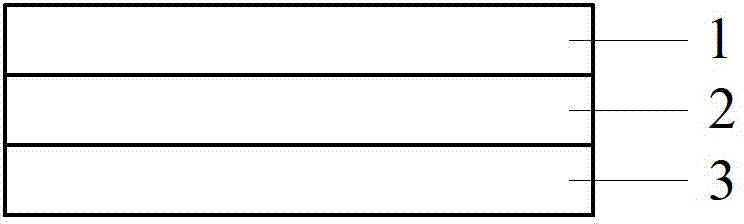

[0054] The schematic diagram of the structure of the multi-layer plastic composite barrier sheet in this embodiment is as follows figure 1 with figure 2 shown.

[0055] Such as figure 1 As shown, the multi-layer plastic composite barrier sheet includes a substrate layer 1 , an adhesive layer 2 and an inner film layer 3 , and the substrate layer 1 and the inner film layer 3 are bonded together through the adhesive layer 2 .

[0056] Substrate layer 1: High-impact polystyrene (HIPS) is Dow Chemical, model 484H; general-purpose polystyrene (GPPS) is Dow Chemical, model 666H; color masterbatch is PolyOne color masterbatch, white food grade;

[0057] Wherein, the substrate layer 1 is a polystyrene sheet, the mass ratio is HIPS:GPPS:white masterbatch=70:28:2, and the thickness is 1000 μm.

[0058] Adhesive layer 2: the hot melt adhesive is German Henkel, type EVA; the thickness is 30 μm.

[0059] Intima layer 3: the thickness is 150 μm;

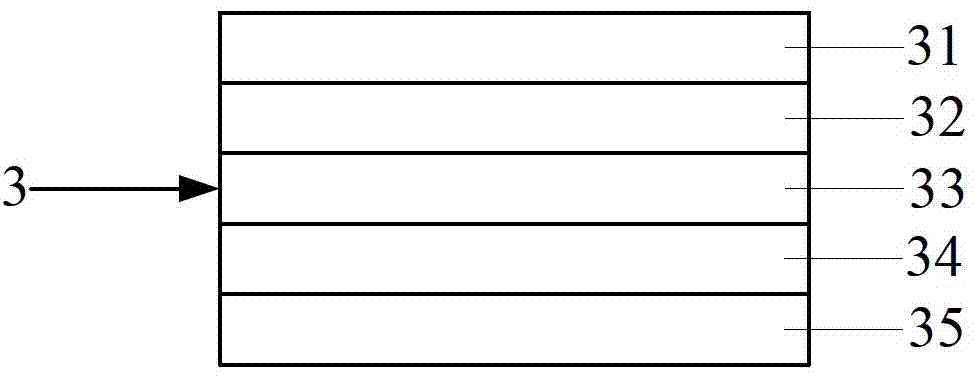

[0060] Such as figure 2 As shown, th...

Embodiment 2

[0073] The difference between this example and Example 1 is that the mass ratio of materials in the polystyrene sheet as the material of the substrate layer 1 is HIPS:GPPS:white masterbatch=30:65:5, and the thickness is 800 μm.

[0074] The inner film layer 3 is a five-layer co-extruded film with a total thickness of 200 μm, and the barrier material layer 33 is polyvinylidene chloride (PVDC) sourced from Dow, model SARAN.

[0075] The first adhesive resin layer 32 and the second adhesive resin layer 34 are Bynel 3860 adhesive resin, which comes from DuPont, USA.

[0076] After testing the performance of the product of this embodiment is as follows:

[0077] Tensile strength (longitudinal and horizontal) 20MPa; peel strength (vertical and horizontal, substrate and inner film layer) 15.0N / 15mm; heating dimensional change rate, longitudinal -2.5%, transverse 0; sheet oxygen transmission rate 1.4cm 3 / m 2 .24h.atm; Formed empty cup oxygen transmission rate 0.30cm 3 / pkg.day (me...

Embodiment 3

[0079] The difference between this embodiment and embodiment 1 is:

[0080] Substrate layer 1: High-impact polystyrene (HIPS) is Yangzi BASF's model 476L; general-purpose polystyrene (GPPS) is Dow Chemical, model 666H; color masterbatch is PolyOne color masterbatch, white food grade ;

[0081] Wherein, the substrate layer 1 is a polystyrene sheet, the mass ratio is HIPS:GPPS:white masterbatch=60:20:1, and the thickness is 800 μm.

[0082] Adhesive layer 2: the hot melt adhesive is German Henkel, type EVA; the thickness is 30 μm.

[0083] Intima layer 3: the thickness of the intima layer is 100 μm;

[0084] Material A layer 31 is (ethylene-vinyl acetate) copolymer (the source is DuPont Easy, model 3175);

[0085] The first adhesive resin layer 32 is adhesive resin, the source is DuPont Bynel, and the model is Bynel 4157;

[0086] The barrier material layer 33 is (ethylene / vinyl alcohol) copolymer (EVOH), sourced from Kuraray, Japan, model EVALJ171B, with a thickness of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com