Chemical nickel plating waste water circulating reclamation and nickel resource circulating reutilization method

A technology of electroless nickel plating and water circulation, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Waste liquid and other problems, to achieve the effect of good water quality

Inactive Publication Date: 2012-12-19

宋洪华 +1

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] (1) Due to the use of the electrocoagulation method, the conductivity of the washing water is very low, only about 400-600us / cm, so in order for the electrocoagulation to proceed smoothly, it is necessary to use a high-concentration waste liquid with a ratio of about 1:40. Low-concentration washing water mixed together for processing

However, in fact, manufacturers with chemical nickel wastewater mostly transport their high-concentration waste liquid out of the commission to be treated by qualified manufacturers outside. There is no input of high-concentration waste liquid for treatment together, and the separate washing water must be treated by electrocoagulation. Before adding sodium chloride to increase the conductivity, electrocoagulation can be carried out

[0006] (2) Even if the manufacturer does not outsource the treatment of the high-concentration waste liquid and handles it all by itself, because the nickel-containing waste liquid contains a high amount of hypophosphite and phosphorous acid, it is necessary to remove the hypophosphite and phosphorous acid only by adding an oxidant. After the phosphorous acid is oxidized to orthophosphate, it forms iron phosphate precipitation with the iron ions dissolved by electrocoagulation to make the phosphorus reach the standard. The actual operation is not very stable, and the high-concentration waste liquid also contains high-concentration COD. So COD is also easy to exceed the standard

[0007] (3) Since the nickel standard needs to be <0.1mg / L, it is indeed a very strict standard. Since there is still electrocoagulation treated water to be discharged, there is a risk of nickel exceeding the standard if there is water discharge

In addition, the old equipment, the wear and tear of the plate and the negligence of personnel operation will all cause the risk of excessive discharge water

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

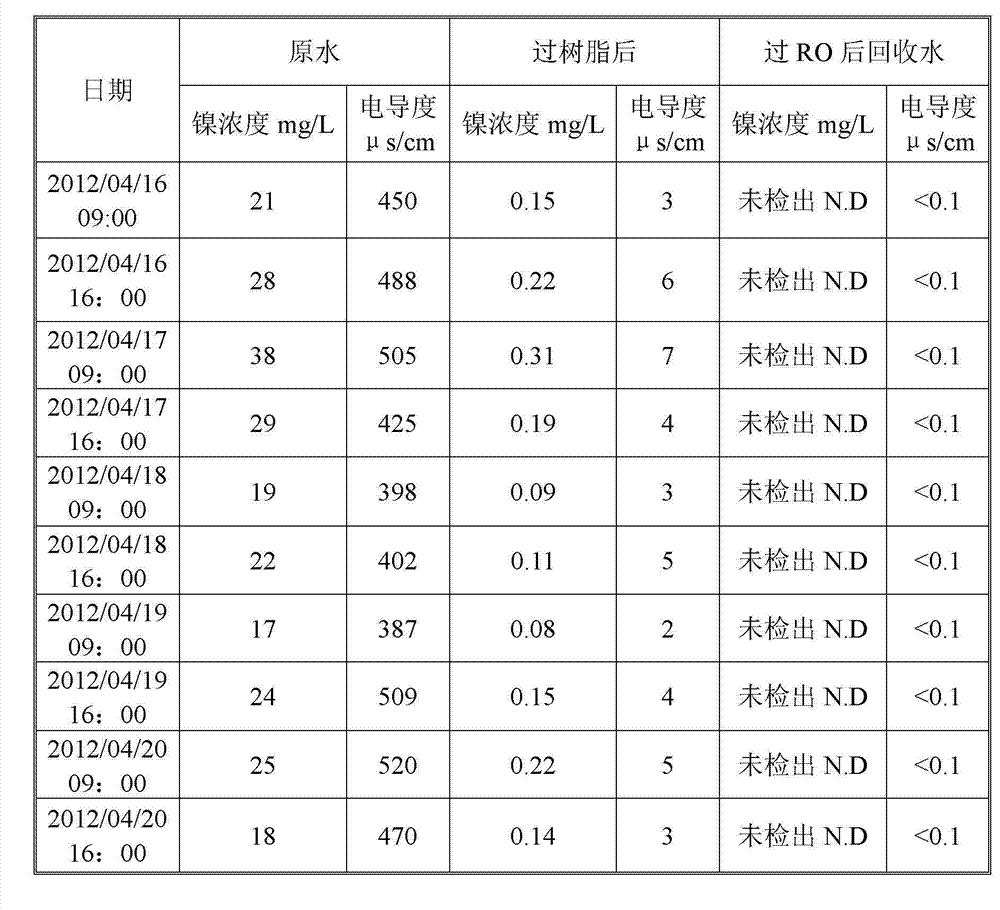

[0025] The present invention will be described in further detail below in conjunction with specific examples.

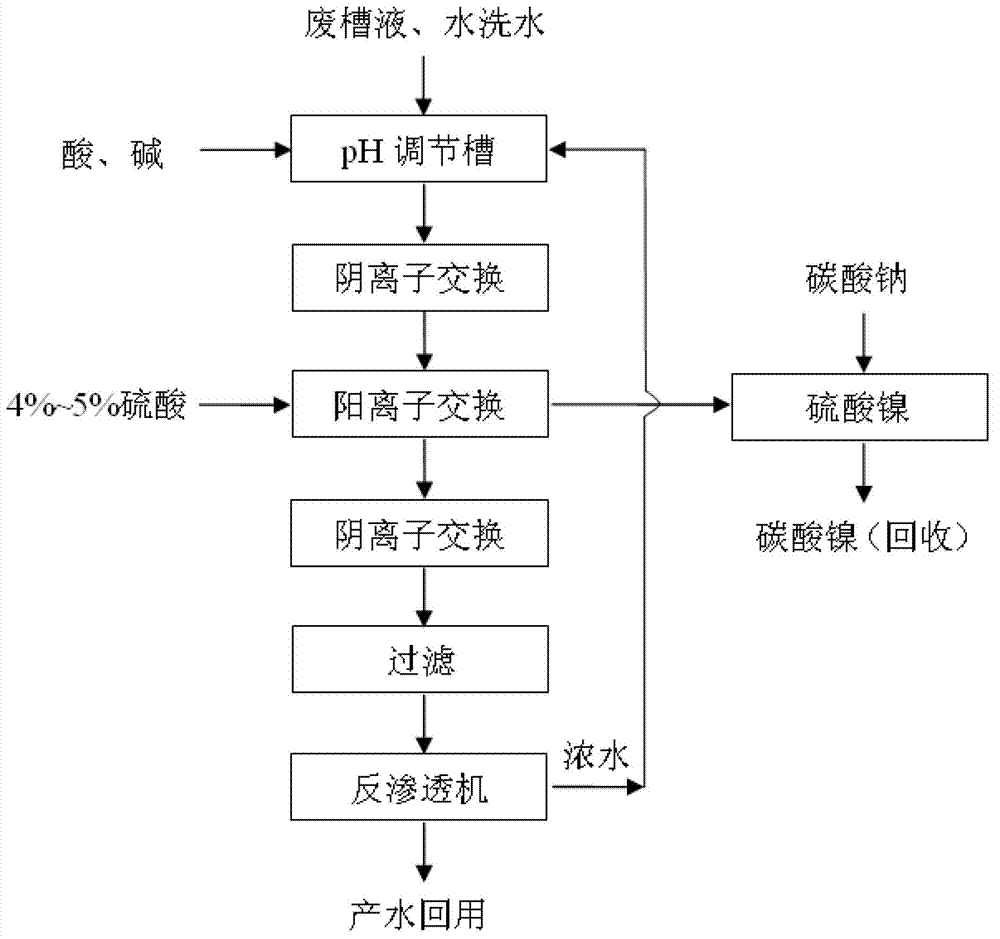

[0026] Such as figure 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a chemical nickel plating waste water circulating reclamation and nickel resource circulating reutilization method which comprises the following steps: (1) sending the chemical nickel plating waste water into a strongly-alkaline anion exchange resin to carry out complex adsorption and decomplexation treatment, thereby destabilizing nickel complexation; (2) adsorbing nickel ions contained in the nickel plating waste water treated by the step (1) with a strongly-acidic cation exchange resin; (3) adsorbing residual anions in the waste water treated by the step (2) with a strongly-alkaline anion exchange resin to lower the electrical conductivity; (4) filtering to remove suspended particles, colloidal matters or organic matters in the waste water obtained in the step (3); and (5) treating the waste water treated by the step (4) with a reverse osmosis apparatus, wherein the produced water can be recycled, and thick water generated by the reverse osmosis apparatus can be circulated back to the step (1). Since zero water is discharged in water circulating reclamation, the problem of overproof discharge water does not exist, and the nickel in the raw waste water is prepared into basic nickel carbonate as a recycled resource.

Description

technical field [0001] The invention relates to a method for treating nickel-containing wastewater discharged from industries such as printed circuit boards (PCBs) and electroplating, and realizing resource recovery and recycling. Background technique [0002] Electroless nickel plating is widely used in printed circuit boards ( PCB), electronic components, metal plating and many industries. However, chemical nickel plating is different from electroplating nickel. The film on it is an alloy of nickel and phosphorus. Some salts and phosphorus will accumulate during the electroplating process, so the stability of the plating solution is worse than that of electroplating nickel. Usually, 5-8 It is aging after about one cycle, and the plating solution needs to be renewed. [0003] Electroless nickel plating waste bath solution and washing water are mainly polluted by high concentrations of hypophosphite and phosphite, so there is high phosphorus pollution, and because of preci...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/04C01G53/06C02F1/42

Inventor 宋洪华杨注程王汉勤

Owner 宋洪华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com