Special rapeseed fertilizer and preparation method of special rapeseed fertilizer

A technology for special fertilizer and rapeseed, which is applied in the field of special fertilizer for rapeseed and its preparation, can solve the problems of rapeseed nutritional quality decline, insufficient organic matter, poor stress resistance, etc., and achieve the effects of reducing pesticide residues, high utilization rate, and reducing the amount of fertilizer applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

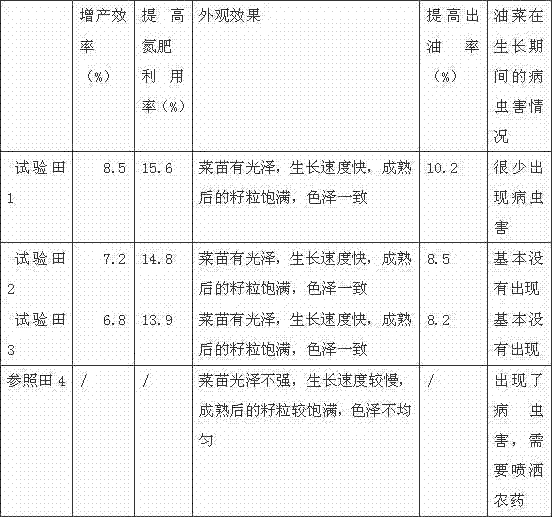

Examples

Embodiment 1

[0026] Weigh 40 kg of agricultural straw, 30 kg of coated urea, 10 kg of monoammonium phosphate, 10 kg of coated ammonium sulfate, 16 kg of coated potassium chloride, 20 kg of plant ash, 1 kg of manganese sulfate, ferrous sulfate, magnesium sulfate, 0.1 kg of zinc sulfate, Boric acid 0.1kg, volcanic ash 12kg, charcoal 5kg, neem fruit powder 3kg, babu powder 4kg, bagasse 10kg, quartz sand 15kg, weathered coal 22kg, carboxymethyl cellulose 3kg, 30% sulfuric acid 15kg, lime 10kg, animal hair 15kg, wintergreen oil 1kg,

[0027] Preparation:

[0028] (1) First add animal hair to 30% sulfuric acid, hydrolyze it for 1-2 hours at 100-110°C to generate amino acids, then add lime to neutralize to a pH value of 6.0-6.8, then add carboxymethyl cellulose, and finally add sulfuric acid Dissolve manganese, ferrous sulfate, magnesium sulfate, zinc sulfate, and boric acid, react at 90-105°C for 5-6 hours, and generate amino acid chelated micro and medium fertilizer liquids;

[0029] (2) ...

Embodiment 2

[0035] Weigh 45 kg of agricultural straw, 30 kg of coated urea, 11 kg of monoammonium phosphate, 12 kg of coated ammonium sulfate, 18 kg of coated potassium chloride, 22 kg of plant ash, 2 kg each of manganese sulfate, ferrous sulfate, magnesium sulfate, 0.3 kg of zinc sulfate, Boric acid 0.2kg, volcanic ash 12kg, charcoal 6kg, neem fruit powder 4kg, babu powder 3kg, bagasse 12kg, quartz sand 12kg, weathered coal 20kg, carboxymethyl cellulose 4kg, 30% sulfuric acid 18kg, lime 8kg, animal hair 12kg, wintergreen oil 1kg,

[0036] The preparation method is the same as in Example 1.

Embodiment 3

[0038] Weigh 50 kg of agricultural straw, 25 kg of coated urea, 10 kg of monoammonium phosphate, 10 kg of coated ammonium sulfate, 17 kg of coated potassium chloride, 30 kg of plant ash, 2 kg of manganese sulfate, ferrous sulfate, magnesium sulfate, 0.1 kg of zinc sulfate, Boric acid 0.1kg, volcanic ash 12kg, charcoal 5kg, neem fruit powder 3kg, babu powder 4kg, bagasse 10kg, quartz sand 15kg, weathered coal 22kg, carboxymethyl cellulose 3kg, 30% sulfuric acid 15kg, lime 10kg, animal hair 15kg, wintergreen oil 2kg,

[0039] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com