High-yield bacterial cellulose fermentation medium and fermentation method of bacterial cellulose

A technology of bacterial cellulose and fermentation medium, which is applied in the field of bacterial cellulose high-yield fermentation medium and bacterial cellulose fermentation, and can solve the problems of low bacterial cellulose production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

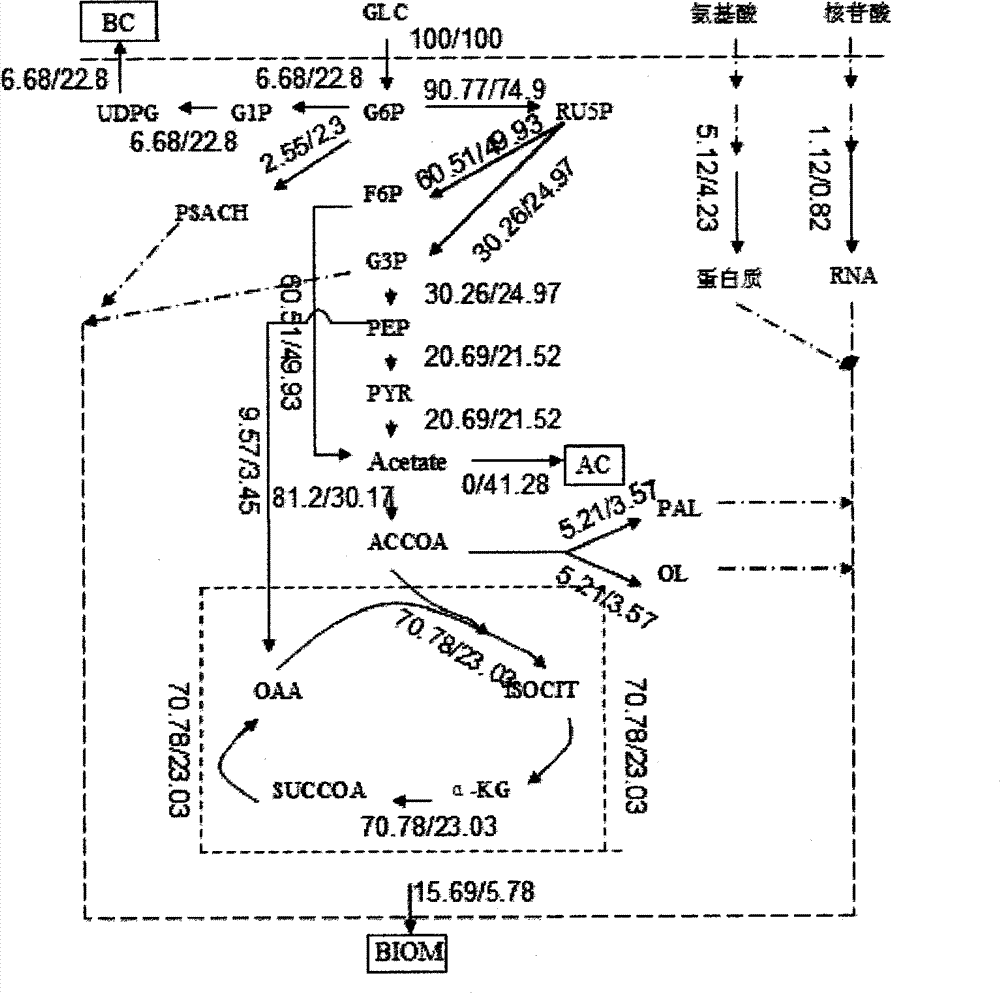

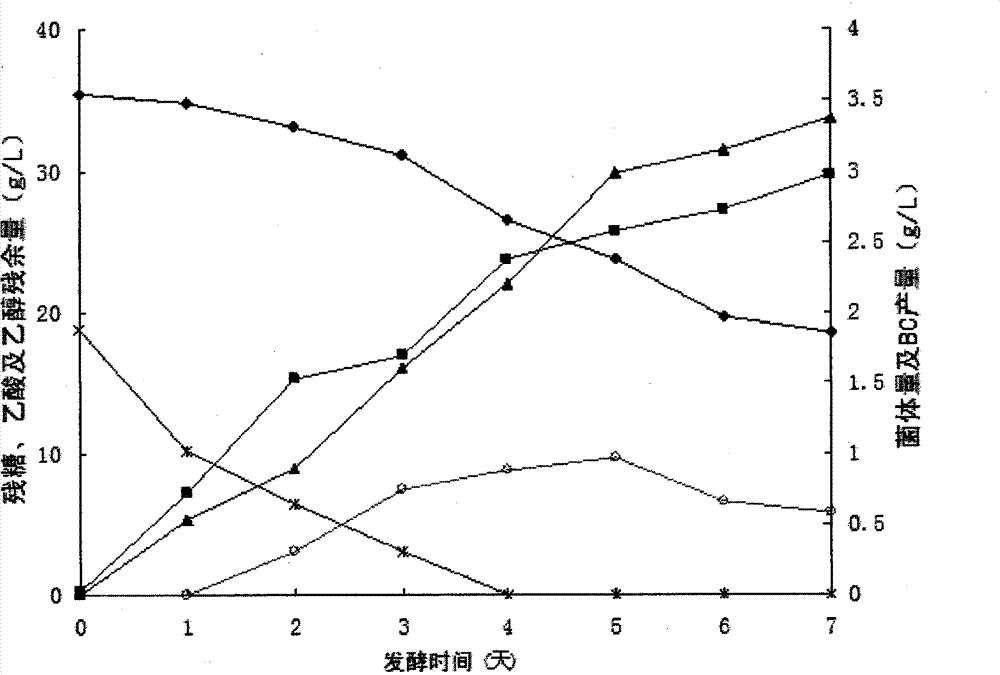

[0017] Specific embodiment one: the bacterial cellulose high-yield fermentation culture medium of this embodiment consists of 3.5%~4.5% glucose, 0.30%~0.36% beef extract, 0.18%~0.22% yeast extract, 0.21%~0.23% Disodium hydrogen phosphate, 0.454%-0.458% dipotassium hydrogen phosphate, 2.22%-2.23% ethanol, 0.15%-0.25% sodium citrate and the rest distilled water.

[0018] The bacterial cellulose high-yield fermentation medium in this embodiment reduces the flow rate of the HMP pathway, which is beneficial to the synthesis of bacterial cellulose; at the Acetate node, the waste caused by the invalid carbon cycle entering the TCA cycle is reduced, so that more metabolic flow enters the Bacterial cellulose synthesis pathway.

[0019] The addition of ethanol and lactic acid in the bacterial cellulose high-yield fermentation medium of this embodiment can quickly oxidize and enter the TCA cycle for energy generation; in addition, due to the rapid oxidation of ethanol, ATP with high ener...

specific Embodiment approach 2

[0021] Specific embodiment two: the bacterial cellulose high-yield fermentation medium of the present embodiment consists of 3.8%~4.2% glucose, 0.32%~0.34% beef extract, 0.19%~0.21% yeast extract, 0.215%~0.225% by weight percentage Disodium hydrogen phosphate, 0.455%-0.457% dipotassium hydrogen phosphate, 2.225-2.226% ethanol, 0.18%-0.22% sodium citrate and the rest distilled water.

specific Embodiment approach 3

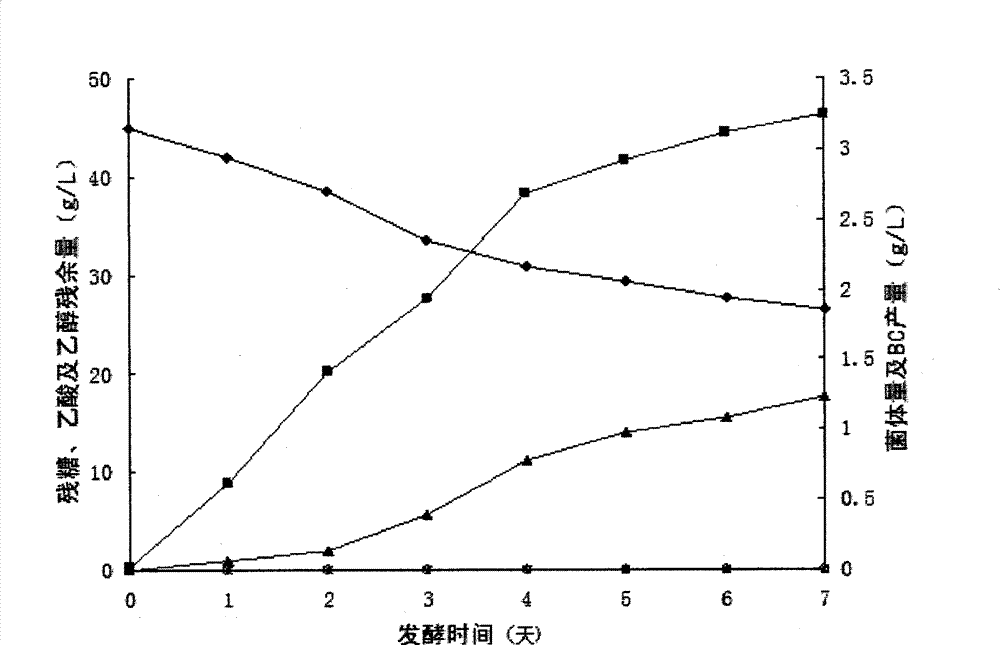

[0022] Specific embodiment three: the bacterial cellulose high-yield fermentation medium of the present embodiment consists of 3.92% glucose, 0.332% beef extract, 0.191% yeast extract, 0.218% disodium hydrogen phosphate, 0.456% dihydrogen phosphate Potassium, 2.226% ethanol, 0.2% sodium citrate and the rest distilled water.

[0023] This embodiment works best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com