Resin inspection well and manufacturing method thereof

A manufacturing method and resin technology, which is applied in the field of resin manholes and its manufacture, can solve problems such as obstruction of drainage, energy waste, and failure of normal construction, and achieve the effects of saving construction costs and shortening the installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

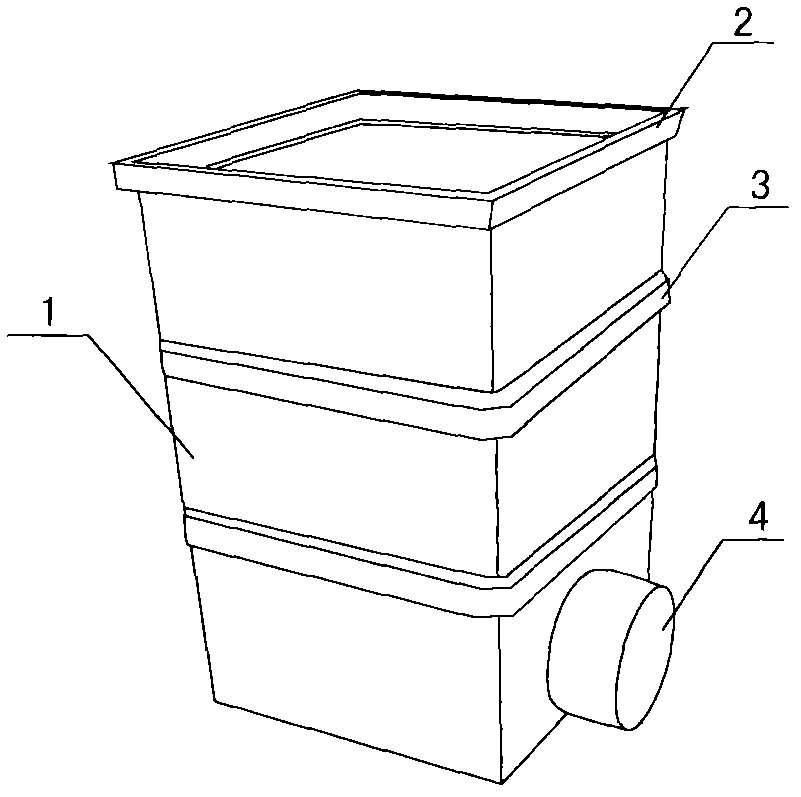

[0013] like figure 1 As shown, a resin inspection well is composed of a well body 1, a flange ring 2, a reinforcing rib 3 and a pipe joint 4, wherein the outer side of the well body 1 is evenly distributed with a reinforcing rib 3, and the lower end of the well body 1 is provided with a pipe joint 4. The blue ring 2 is socketed with the upper end of the well body 1; during specific implementation, take the preparation of 1000g of resin inspection well material as an example, first stir the resin, glass fiber, filler, colorant, and curing agent (Group A), and the various components The weight accounted for is: 500g of resin, 180g of glass fiber, 160g of filler, 10g of colorant, 75g of curing agent (group A); then mix the stirred resin with 75g of curing agent (group B) and pour it into the mold Inside, and finally demoulding, the finished product can be obtained.

[0014] The invention uses resin as the main material for manufacturing inspection wells, which can completely rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com