Method for determining content of arsenic pentoxide and arsenic trioxide

A technology for arsenic pentoxide and arsenic trioxide, which is applied in the field of separate determination of the content of arsenic pentoxide and arsenic trioxide, can solve the problem of lack of accurate quantification of arsenic trioxide and the like, and achieve the effect of a fast and accurate detection method and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

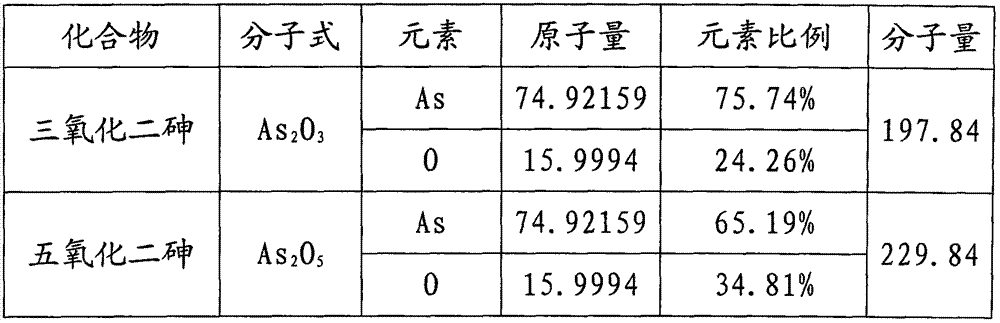

[0017] In this embodiment, diarsenic pentoxide and diarsenic trioxide in plastic samples are determined.

[0018] Take an appropriate amount of sample and place it in a freezer pulverizer to pulverize and mix well. Weigh two 0.5g samples, add 10mL absolute ethanol to one sample and shake at room temperature to extract for 60min, then filter, wave the filtrate on the electric heating plate until nearly dry, add 8mL nitric acid and 2mL perchloric acid to digest on the electric heating plate, After the digestion is complete, dilute to 50 mL with deionized water. Add 10mL of sulfuric acid to the other sample and heat it on the electric heating plate to make it carbonized. After the white smoke is exhausted, slowly add 5mL hydrogen peroxide after cooling. After the reaction is stable, heat it on the electric heating plate. Make up to 50mL.

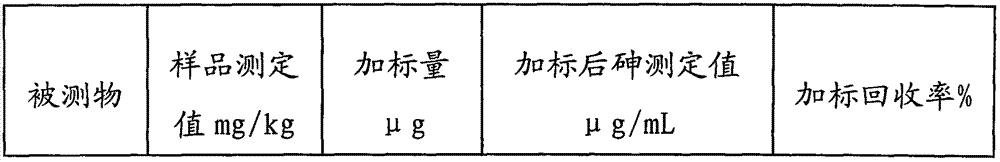

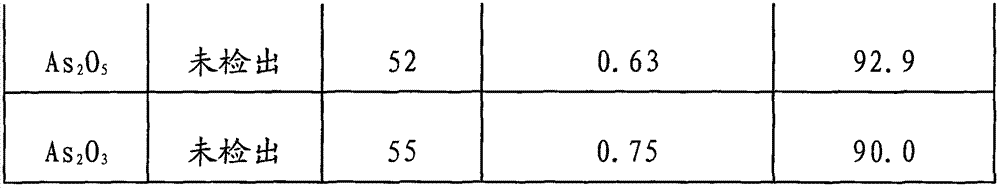

[0019] The content of arsenic in the two solutions was determined by inductively coupled plasma atomic emission spectrometer. The arsenic m...

Embodiment 2

[0026] Carry out with reference to Example 1, the difference is that the sample is leather, two parts of 1g samples are weighed, one part is added with 20mL ethanol for extraction, the extract is digested with acid, the other part is added with 10mL nitric acid and 2mL perchloric acid for digestion, two parts All samples after complete digestion were adjusted to 50 mL.

[0027] Table 3 Relevant data for the determination of arsenic pentoxide and arsenic trioxide in this example

[0028]

[0029] Obviously, those skilled in the art can use the present invention to measure the content of diarsenic pentoxide and diarsenic trioxide in electronic products respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com