Correction method of distribution of quenching stress field of aluminum alloy thick plate

An aluminum alloy, stress field technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large difference, deviation, uneven plastic deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The thickness of the sample plate is 30mm.

[0072] (1) Determination of heat transfer coefficient for thick plate quenching.

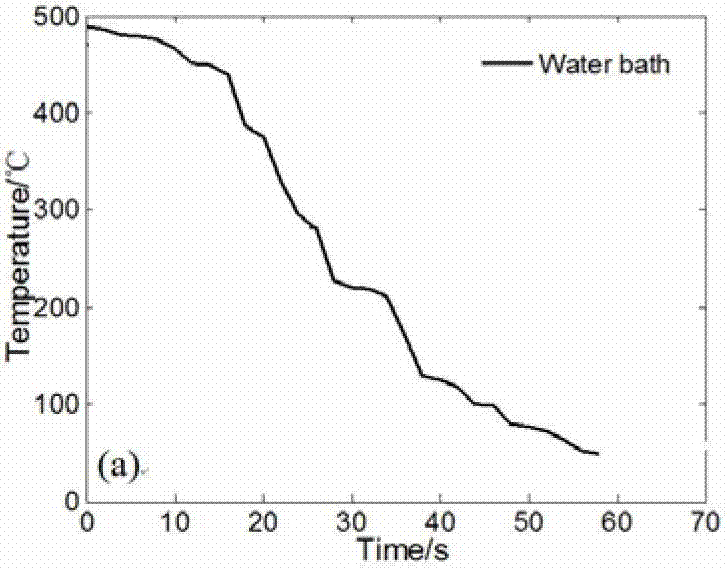

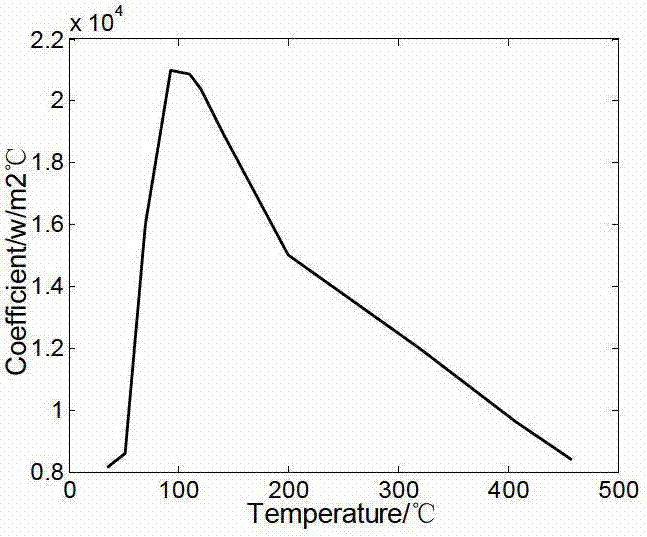

[0073] The quenching and cooling curve of the core of the test thick plate is as follows: figure 1 As shown, the curve is discretized with a time step of Δτ=10s, and the initial temperature of the thick plate is assumed to be consistent inside and outside in each discrete interval, and the preliminary heat transfer coefficient h is analyzed and solved. Since the surface heat transfer coefficient is very large during strong convective heat transfer, the , in order to facilitate data processing, the h calculated in each interval can be calculated first i After rounding, weighted average is carried out, and the data list of each key point is 1. figure 2 is the distribution curve of the surface heat transfer coefficient of the quenched thick plate as a function of temperature.

[0074] Table 1

[0075] temperature (degrees)

480 ...

Embodiment 2

[0115] The thickness of the sample plate is 40mm.

[0116] (1) Determination of heat transfer coefficient for thick plate quenching.

[0117] The test correction method for 40mm thick plate, the same heat treatment conditions, its cooling rate, heat transfer coefficient and 30mm thick plate quenching are very close, as shown in Table 4. The curve is discretized with a time step of Δτ=10s, and the preliminary heat transfer coefficient h is analyzed analytically assuming that the initial temperature of the thick plate is consistent inside and outside in each discrete interval.

[0118] Table 4

[0119] temperature (degrees)

480

460

410

230

130

75

50

h(w / m 2 °C)

0

8000

10000

14000

21000

13000

8000

time (seconds)

0

10

20

30

40

50

60

[0120] According to the quenching and cooling data and heat transfer coefficient of the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com