Method for manufacturing N electrode of GaN-based light-emitting diode (LED)

A manufacturing method and electrode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of serious absorption of metal electrodes, large refractive index difference, low light extraction efficiency, etc., to improve light extraction efficiency, facilitate wire bonding, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

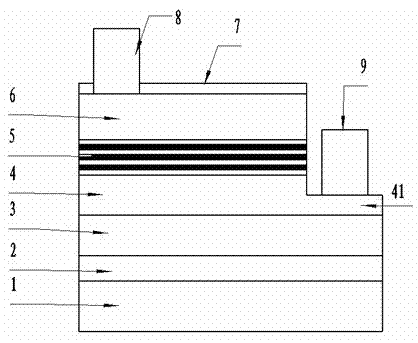

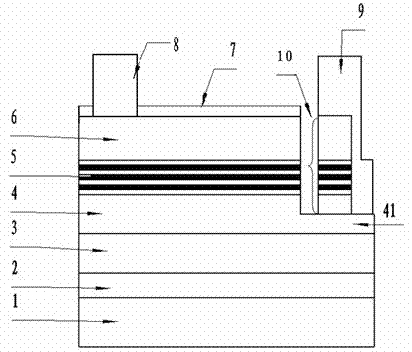

[0009] A method for making the N electrode in a GaN-based LED of the present invention, such as figure 2 shown, including the following steps:

[0010] Step 1: Fabricate GaN epitaxial wafers: use metal organic chemical vapor deposition (MOCVD) to sequentially grow a low-temperature GaN buffer layer 2 with a thickness of 1 μm, an undoped GaN layer 3 with a thickness of 2 μm, and a thickness of An N-GaN layer 4 of 3 μm, a multi-quantum well light-emitting layer 5 with a thickness of 200 nm and a P-GaN layer 6 with a thickness of 700 nm form a GaN epitaxial wafer. Wherein, the semiconductor substrate 1 may be any one of sapphire, silicon, silicon carbide or metal.

[0011] Step 2: ICP (Inductively Coupled Plasma) Mesa Etching of GaN:

[0012] For conventional LEDs, one side of the GaN epitaxial wafer is etched by ICP to remove all the P-GaN layer 6, the multi-quantum well light-emitting layer 5 and the vertical part of the N-GaN layer 4 on one side to form N-GaN 41, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com