Quartz crystal resonator and processing method thereof

A technology of quartz crystal and processing method, which is applied in the direction of electrical components, impedance networks, etc., to achieve the effects of improving parasitic response characteristics, preventing air oxidation, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

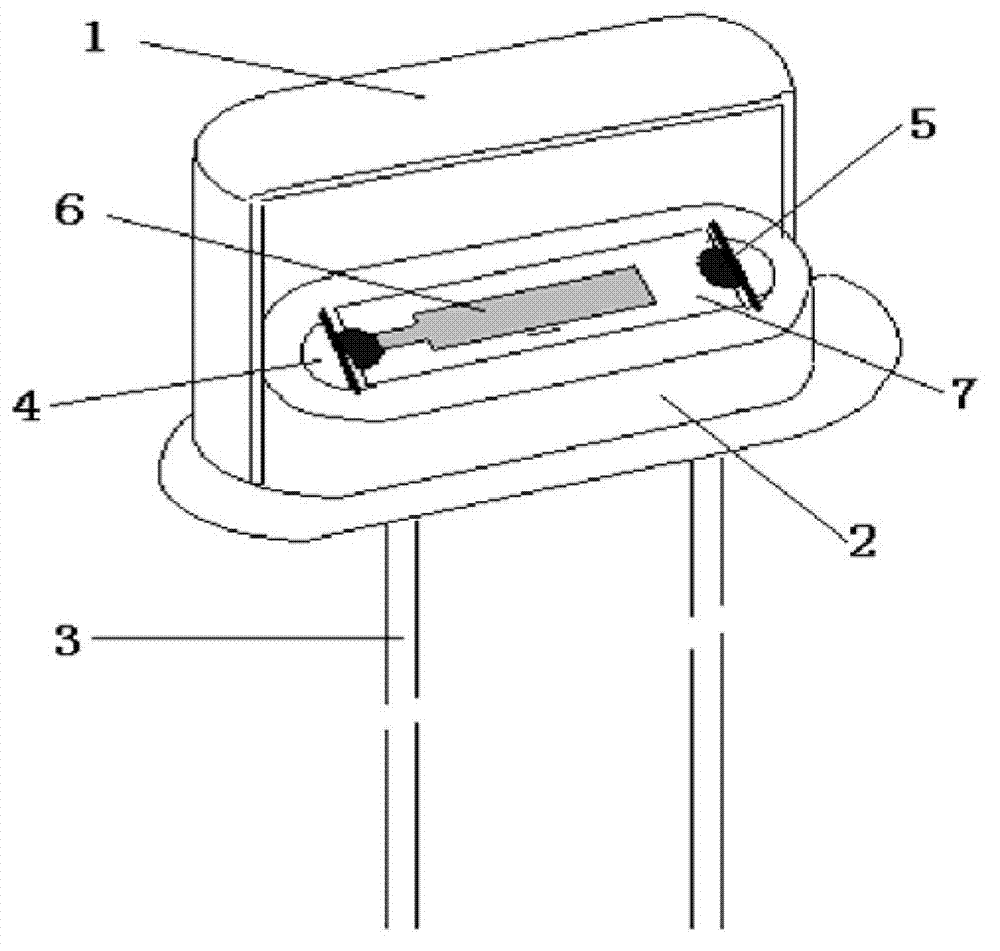

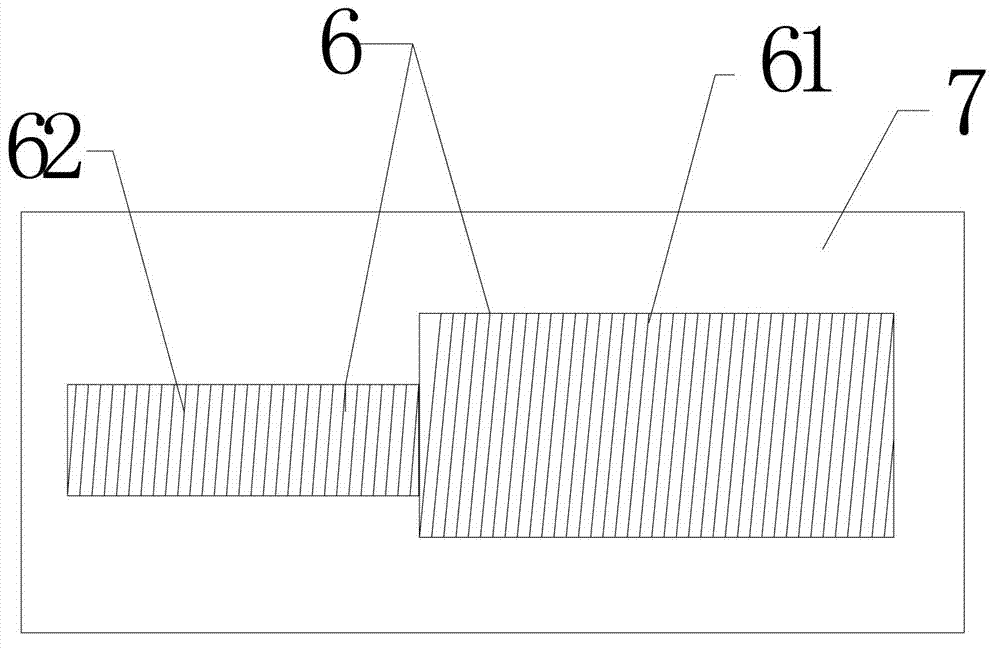

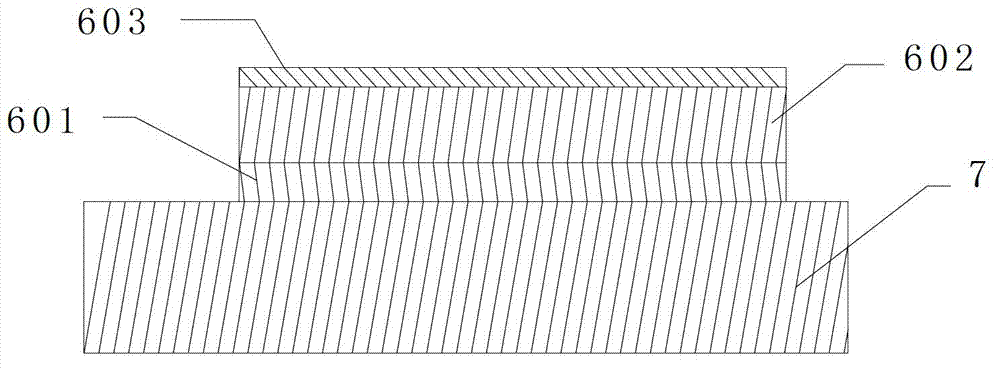

[0031] Such as figure 1 , the quartz crystal resonator disclosed by the present invention includes a housing 1, a base 2, pins 3, a spring sheet 4, conductive glue 5, a coating electrode 6, and a wafer 7; the coating electrode 6 includes a basic electrode 61 and a fine-tuning electrode connected thereto 62 ; the plated electrode 6 is attached to the surface of the wafer 7 , including a lower chrome-plated layer 601 , a silver-plated layer 602 , and an upper chrome-plated layer 603 arranged in sequence from inside to outside.

[0032] Preferably, the basic electrode 61 is a rectangle with a size of 3.0×1.4 mm; the fine-tuning electrode 62 is a rectangle with a size of 2.4×1.0 mm.

[0033] Preferably, the thickness of the lower chromium plating layer 601 is 2 to 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com