Preparation method of visible light full-waveband multilayer antireflection coating

An anti-reflection coating and coating technology, applied in coatings and other directions, can solve the problems of high reflectivity, high transmittance, unsatisfactory light transmittance, and limited use of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

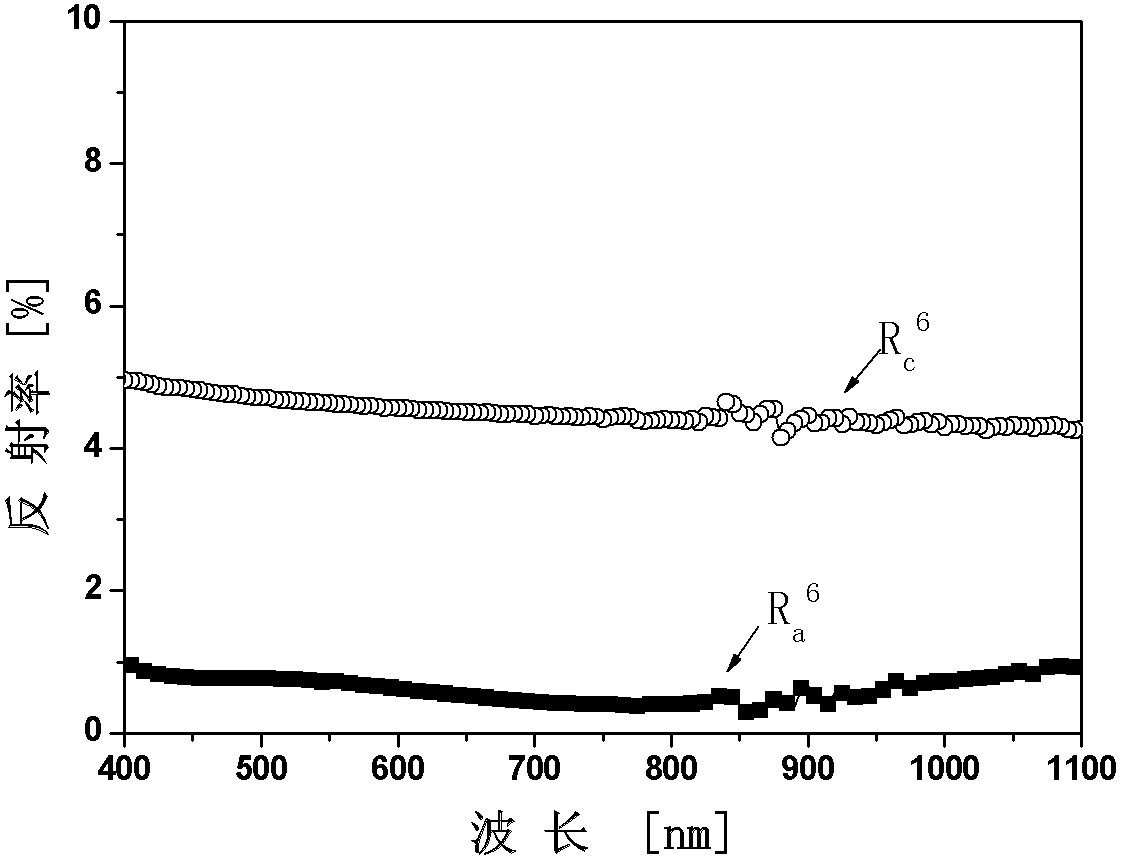

[0048] This embodiment is used to illustrate the preparation method of the multi-layer anti-reflection coating of the present invention and the detection of its adhesion.

[0049] Add 0.1 g of methacryloxysilane-modified silica nanoparticles (13 nm in particle size) to 99.9 g of propylene glycol methyl ether acetate, and stir at 500 rpm to obtain a uniform slurry. Use an ultrasonic cell pulverizer to ultrasonically disperse the above slurry for 1h, and the ultrasonic power is 1200W to obtain the gas phase SiO 2 Nanodispersion.

[0050] Under the condition of a water bath temperature of 50° C., 20.8 g of ethyl orthosilicate was added to 9.2 g of absolute ethanol, and stirred at 500 rpm for 2 h. Add 20ml of ammonia water (1N) and stir for 4h to obtain a uniform and stable sol. After standing for 18h, the sol-gel SiO 2 Nanodispersion.

[0051] Add 0.8 g of photoinitiator Irgacure184 (Ciba) to 20 g of trimethylolpropane triacrylate, stir at 500 rpm to dissolve it completely. ...

Embodiment 2

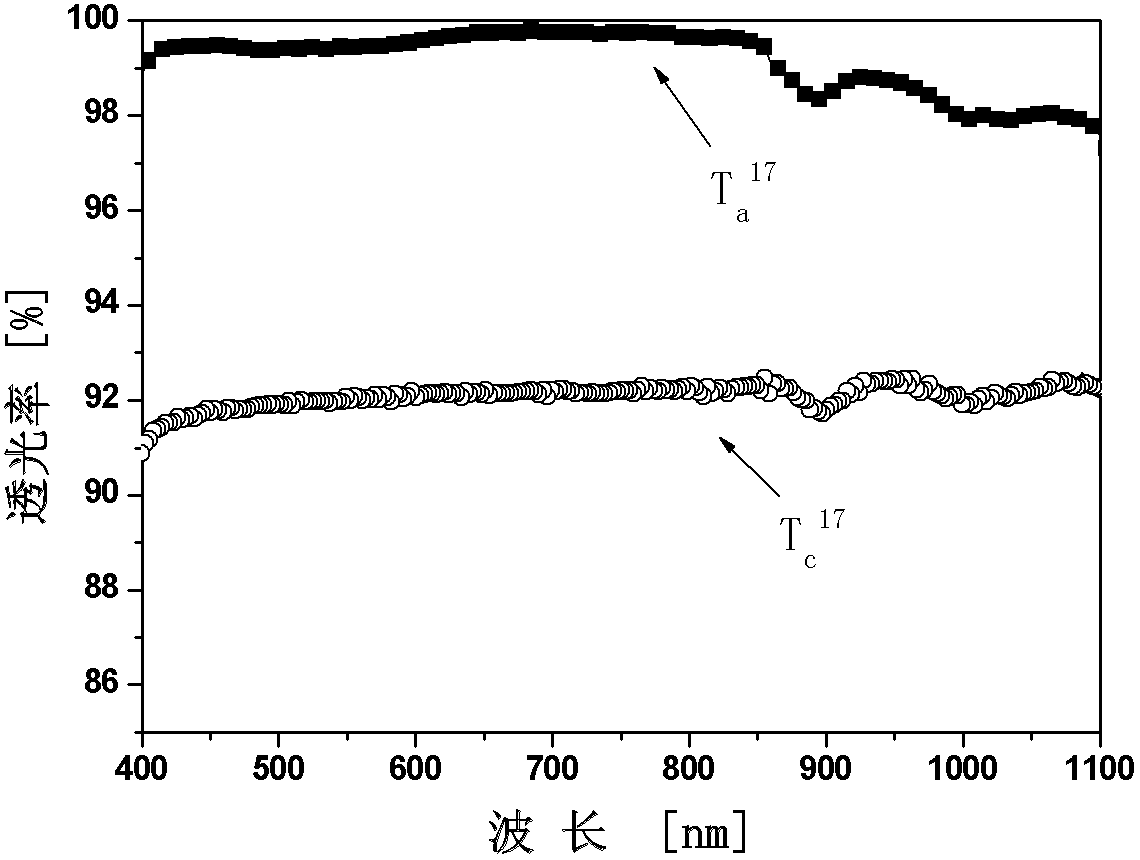

[0055] This example is used to illustrate the preparation method of the multi-layer anti-reflection coating of the present invention.

[0056] Add 0.01 g of trimethylolpropane triacrylate to 99.88 g of absolute ethanol, and stir evenly at 500 rpm. Then add 0.1g unmodified SiO 2 Nanoparticles, stirred at 500 rpm to obtain a homogeneous slurry. Ultrasonic cell pulverizer was used to ultrasonically disperse the above slurry for 1 h, and the ultrasonic power was 1200W. Then, use a planetary ball mill to grind the slurry, the diameter of the grinding ball is 0.5mm, the rotation speed is 500rpm, and the grinding time is 12h to obtain the gas phase SiO 2 Nanodispersion.

[0057] To the above gas phase method SiO 2 Add 0.0004g of photoinitiator Irgacurel84 (Ciba) to the nano-dispersion liquid, and stir it at 500rpm to dissolve it completely.

[0058] Under the condition of a water bath temperature of 50° C., 20.8 g of tetraethyl orthosilicate, 16 g of absolute ethanol and 7 g of ...

Embodiment 3

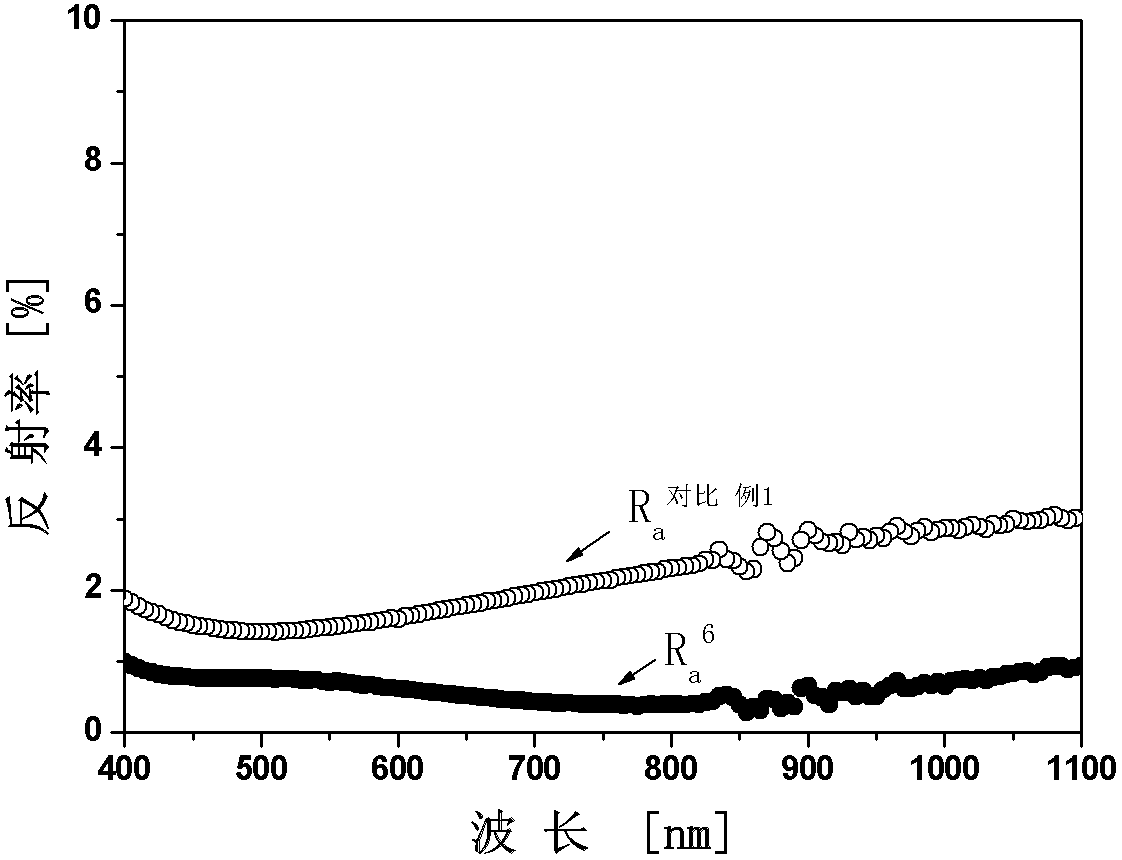

[0061] This example is used to illustrate the preparation method of the multi-layer anti-reflection coating of the present invention.

[0062]72g of absolute ethanol, 24g of propylene glycol methyl ether acetate, 0.2g of acrylate DESMOPHENA450BA (Bayer) and 0.1g of Triton-100 were stirred evenly at 500rpm. Then add 3g of unmodified SiO 2 Nanoparticles, stirred at 500 rpm to obtain a homogeneous slurry. According to the dispersion method identical with embodiment 1, prepare gas phase method SiO 2 Nanodispersion.

[0063] To the above gas phase method SiO 2 Add thermal initiator 0.044g DESMODURN3390BA / SN (Bayer) into the nano-dispersion liquid, stir at 500rpm to make it dissolve completely.

[0064] Under the condition of a water bath temperature of 50° C., 20.8 g of ethyl orthosilicate was added to 15 g of absolute ethanol, and stirred at 500 rpm for 2 h. Add 40ml of ammonia water (1N) and stir for 4h to obtain a uniform and stable sol. After standing for 12h, the sol-gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com