Tobacco flavoring essence temperature sensitive microcapsule, as well as preparation method and application thereof

A technology of flavor and microcapsules for cigarettes, applied in the field of cigarettes, can solve problems such as adverse effects on cigarette quality, uneven diffusion of flavors, etc., and achieve the effects of easy mass production, inhibition of volatilization and loss, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Prepare 1L of 0.5% sodium alginate and polyethylene glycol solution, the molecular weight of polyethylene glycol is 400kDa, the mass ratio of sodium alginate to polyethylene glycol is 1:10, stir and mix evenly and remove air bubbles, set aside. Put 100g of dry microcrystalline cellulose on a fluidized bed granulator, spray 20mL of 50g / L menthol ethanol solution evenly, and then spray the prepared 0.5% sodium alginate and polyethylene glycol evenly under hot air at 40°C 20 mL of the mixed solution was dried to obtain temperature-sensitive menthol essence microcapsules. The menthol content in the obtained microcapsules is 1%, and the film content is 0.1%.

Embodiment 2

[0019] Prepare 1L of 1% sodium alginate and polyethylene glycol solution, the molecular weight of polyethylene glycol is 800kDa, the mass ratio of sodium alginate to polyethylene glycol is 1:1, stir and mix evenly and remove air bubbles, set aside. Put 100g of dry microcrystalline cellulose on a fluidized bed granulator, spray 200mL of 50g / L menthol ethanol solution evenly, and then spray the prepared 1% sodium alginate and polyethylene glycol evenly under hot air at 40°C 100mL of the mixed solution was dried to obtain temperature-sensitive menthol essence microcapsules. The menthol content in the obtained microcapsules is 10%, and the film content is 1%.

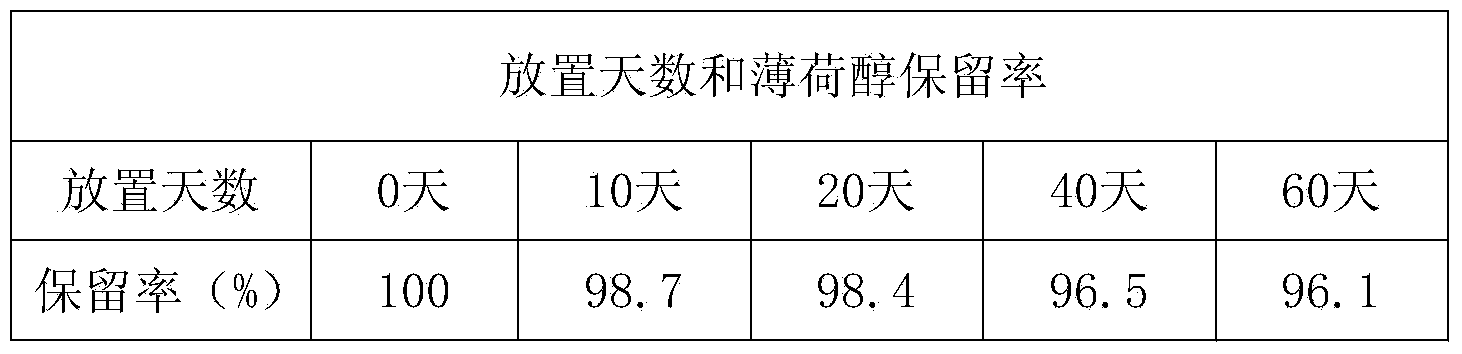

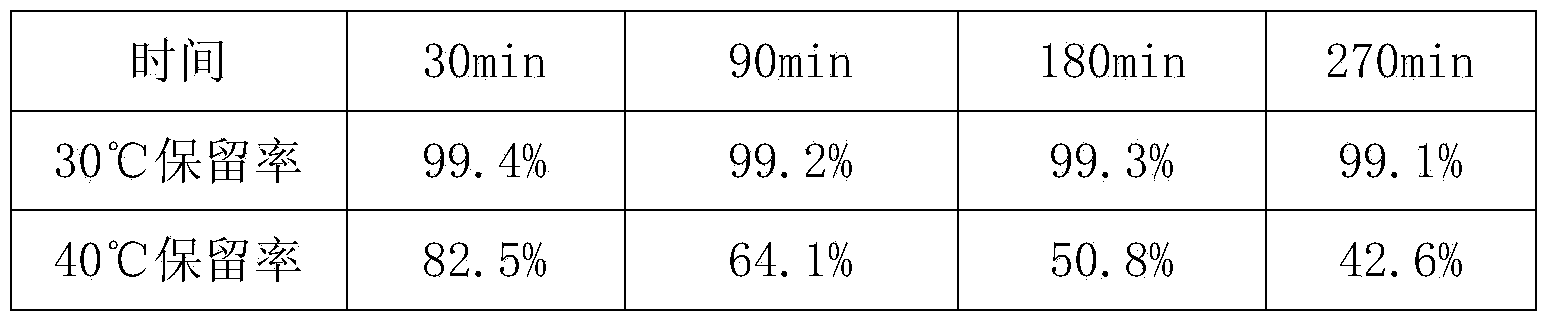

[0020] 20 g of the above-mentioned essence microcapsules were tiled in a glass vessel with a thickness of 2 mm, and their menthol retention rates at different times were measured by gas chromatography at a constant temperature of 30°C. The results are shown in Table 1.

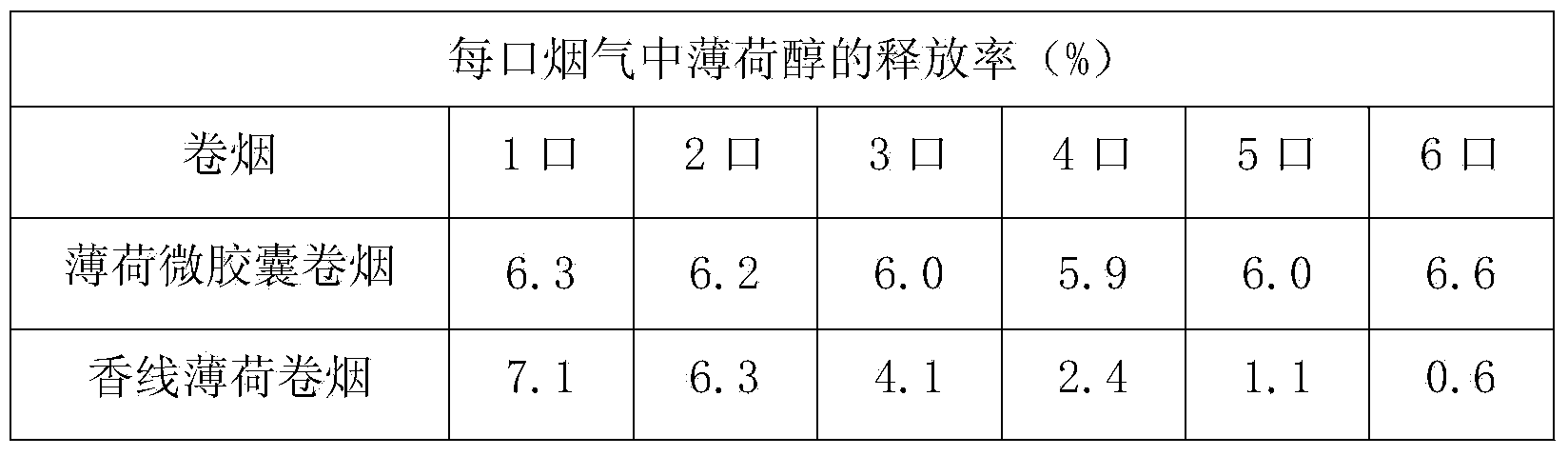

[0021] The ability of table 1 essence microcapsules...

Embodiment 3

[0027] Prepare 1L of 3% sodium alginate and polyethylene glycol solution, the molecular weight of polyethylene glycol is 1000kDa, the mass ratio of sodium alginate to polyethylene glycol is 15:1, stir and mix evenly and remove air bubbles, set aside. Put 100g of dry microcrystalline cellulose on a fluidized bed granulator, spray 300mL of 50g / L menthol ethanol solution evenly, and then spray the prepared 3% sodium alginate and polyethylene glycol evenly under hot air at 40°C 100mL of the mixed solution was dried to obtain temperature-sensitive menthol essence microcapsules. The menthol content in the obtained microcapsules is 15%, and the film content is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com