Chemical deplating liquid for nickel-plating layer of copper busbar and application method of chemical deplating liquid

A technology of deplating solution and nickel plating layer, which is applied in the field of rework and deplating formula, which can solve the problems of formula 2, such as high temperature, high production cost, difficult maintenance and control, etc., and achieve the effect of smooth surface, low cost and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific embodiment the present invention is further explained and illustrated

[0041] 1.1 Experimental reagents

[0042] Table 1 Names and grades of experimental reagents

[0043]

[0044] 1.2 Experimental Analysis

[0045] In order to comprehensively consider the influence of various components on the effect of nickel removal, the above-mentioned several components were used to carry out orthogonal optimization experiments, and 4 tests were performed at each level. The orthogonal test design is shown in Table 2.

[0046] Table 2 Orthogonal test factor level table

[0047]

[0048] 1.3 Experimental Discussion

[0049] Table 3 Recipe optimization test orthogonal table L 16 (4 5 )

[0050]

[0051]

[0052] Note: A indicates the corrosion condition, AAAAA is serious, A is slight, descending in order.

[0053] 1.3.1 Analysis of substrate corrosion

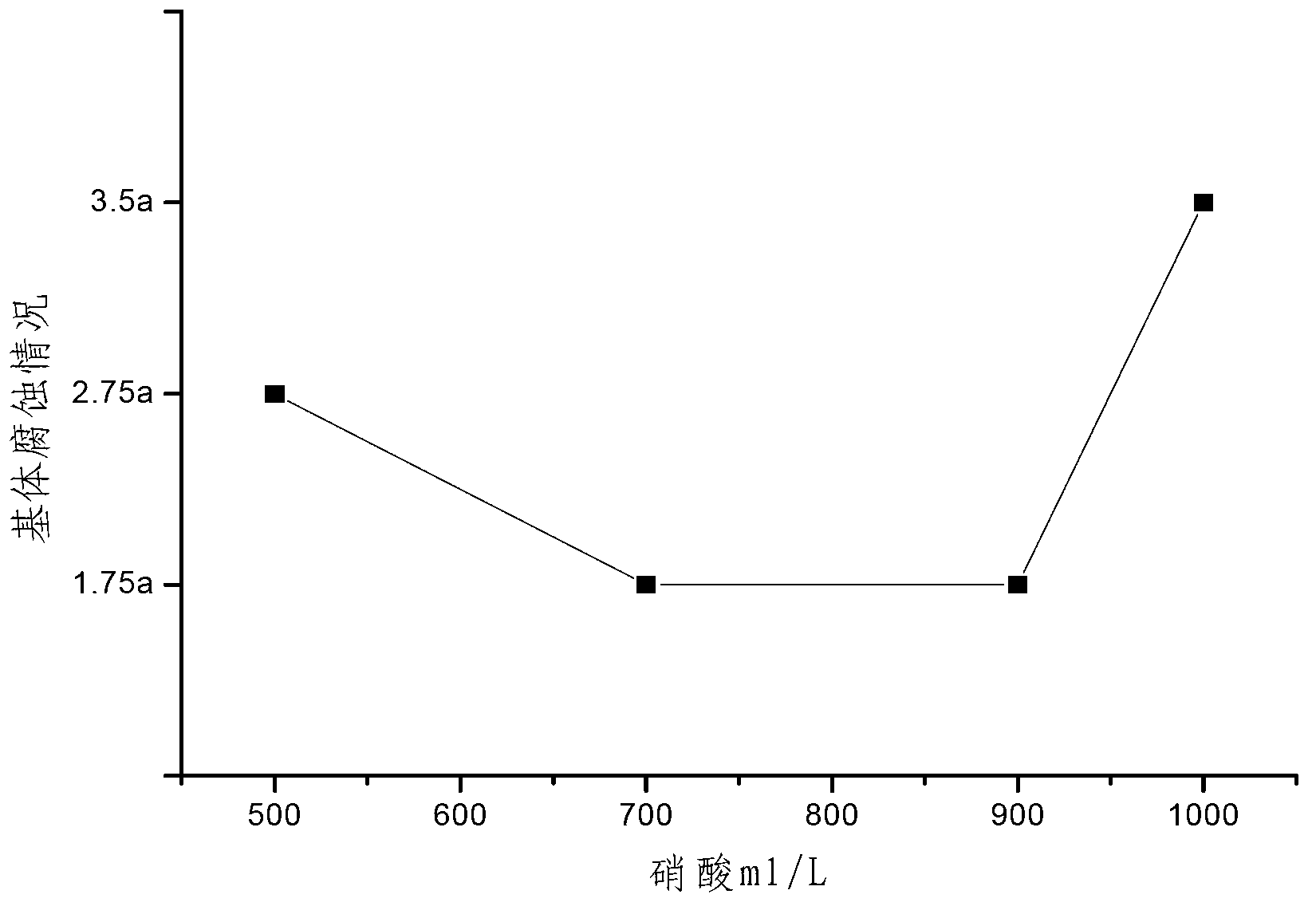

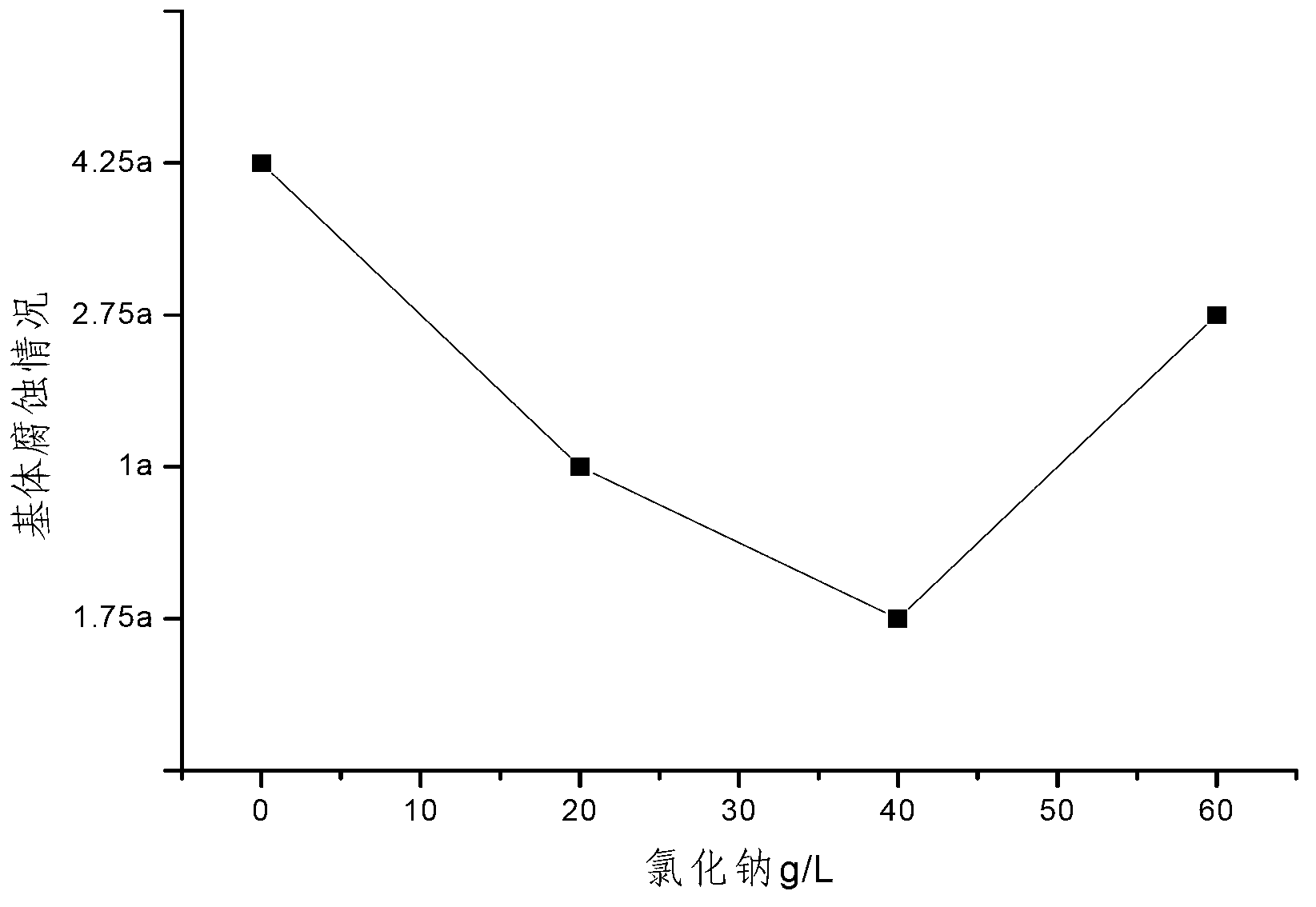

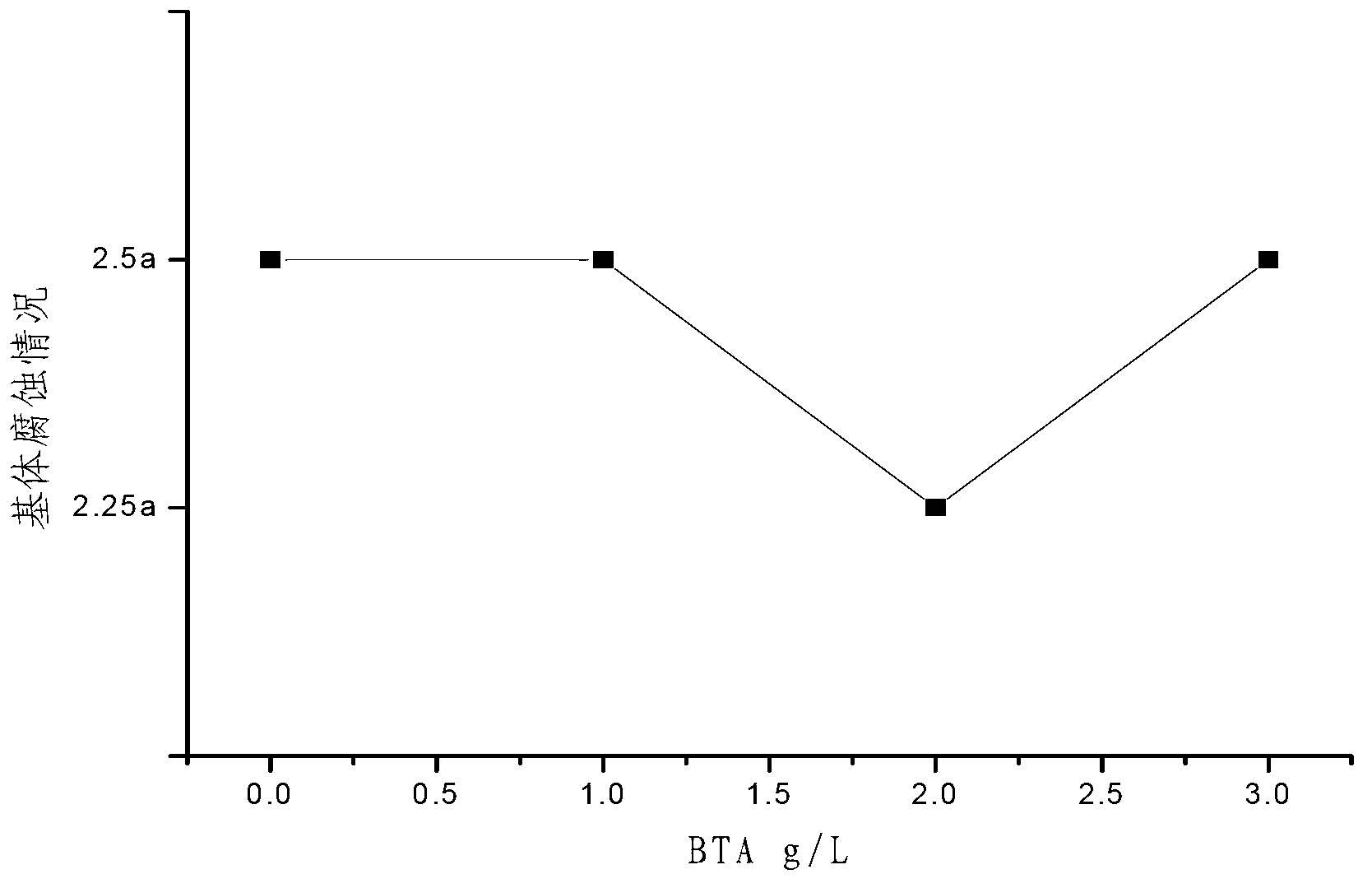

[0054] First, analyze the influence of the nitric acid factor on the corrosio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com