High-power white-light LED fluorescent powder coating method

A phosphor, high-power technology, used in optics, opto-mechanical equipment, instruments, etc., can solve the problems of uneven light field distribution, device failure, difficult to accurately control the thickness and shape of the phosphor layer, and improve light uniformity. , Reduce the effect of spatial light chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

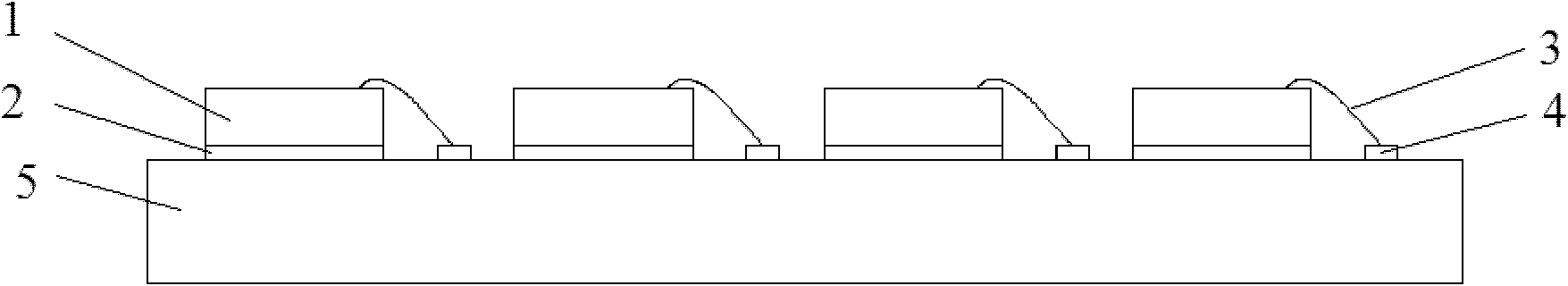

Method used

Image

Examples

Embodiment 1

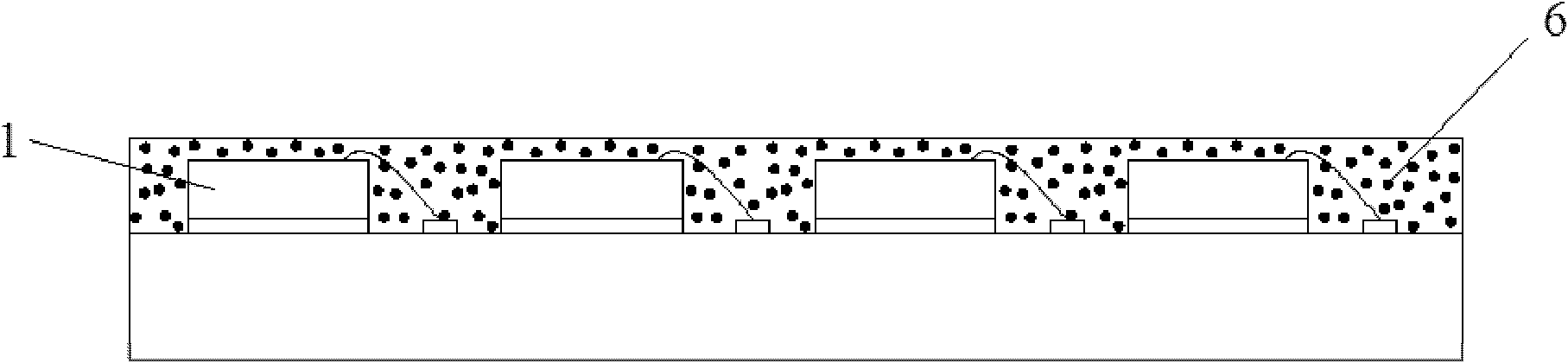

[0038] Mix phenolic resin, azonaphthoquinone and propylene glycol monomethyl ether acetate according to the concentration ratio of 25:10:65, fully dissolve, and filter twice with 0.25 μm polytetrafluoroethylene ultrafiltration membrane to prepare a new type of resistant For high-temperature positive photoresist, store in a refrigerator at 5-20°C and keep it sealed and protected from light.

[0039] Prepare the AB silica gel at a ratio of 1:1, then mix it with an appropriate amount of fluorescent powder, and stir evenly to make fluorescent powder glue.

[0040] Mix and stir the prepared phosphor powder glue and photoresist according to the mass of 75 parts and 25 parts evenly to prepare photoresist containing phosphor powder, and place it still until the bubbles disappear.

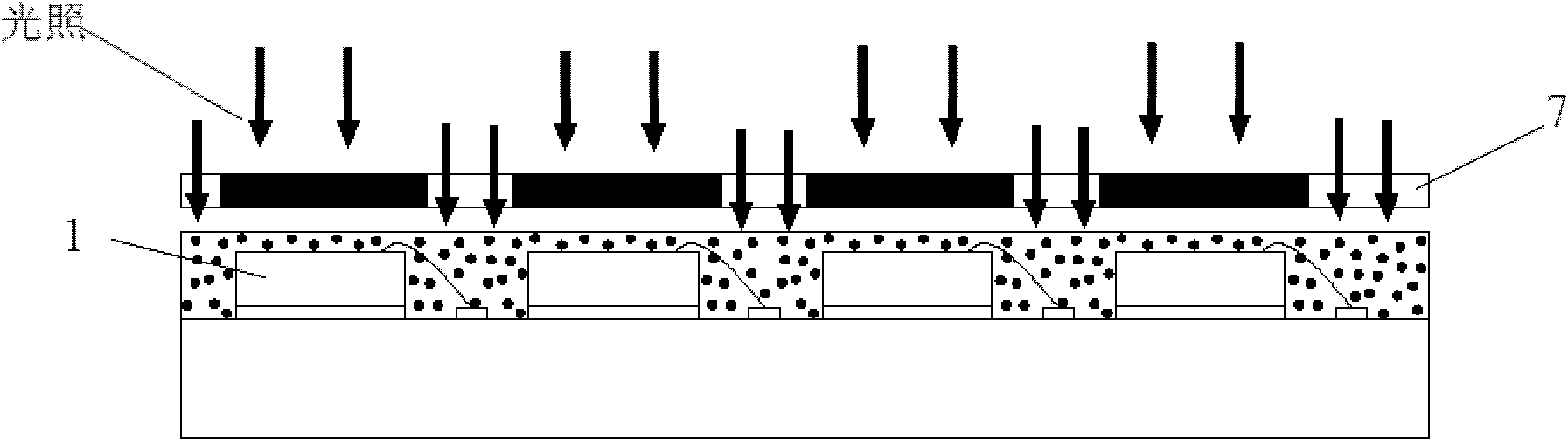

[0041]Coat the photoresist containing the phosphor on the LED chip, and put the photoresist on the homogenizer at a speed of 350rpm for 20s to form a phosphor layer containing the photoresist, and dry it na...

Embodiment 2

[0046] Mix phenolic resin, azonaphthoquinone and propylene glycol monomethyl ether ester according to the concentration ratio of 15:7:78, stir evenly, fully dissolve, and filter twice with 0.25 μm polytetrafluoroethylene ultrafiltration membrane to prepare A new type of high-temperature-resistant positive-type photoresist should be stored in a refrigerator at 5-20°C and sealed away from light.

[0047] Prepare the AB silica gel at a ratio of 1:1, then mix it with an appropriate amount of fluorescent powder, and stir evenly to make fluorescent powder glue.

[0048] Mix and stir the prepared fluorescent powder glue and photoresist according to the mass of 65 parts and 35 parts evenly to make a photoresist containing phosphor powder, and place it still until the bubbles disappear.

[0049] The photoresist containing phosphor is sprayed on the front surface of the LED chip to form a phosphor layer containing photoresist, and air-dried in a dark room.

[0050] The phosphor layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com