Rice ball powder and making process thereof

A technology for rice soup and indica rice, which is applied to the field of rice soup powder and its production technology, can solve the problems of uneven taste, poor fineness of rice soup powder, difficult preservation and the like, and achieves hard aging and agglomeration, promotes digestion, and is not easy to discoloration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

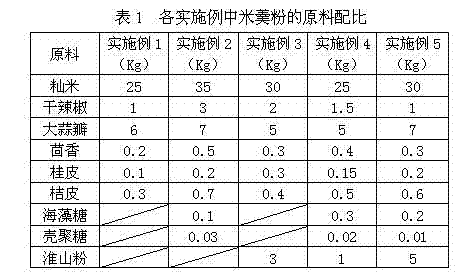

[0034] Weigh indica rice, dried chili, garlic cloves, fennel, cinnamon bark and orange peel according to the proportioning ratio. Indica rice.

[0035] (1) One-time soaking: Soak the indica rice in an aqueous sodium bicarbonate solution with a mass concentration of 0.25% and a temperature of 35°C for 40 minutes, and then drain. The quality of the aqueous sodium bicarbonate solution is 4 times the mass of indica rice.

[0036] (2) Second soaking: Soak the dried indica rice chili, garlic cloves, fennel, cinnamon bark and orange peel in water at 10°C for 1 hour after the first soaking, and then drain.

[0037] (3) Coarse grinding: Grind the indica rice, dried chili, garlic cloves, fennel, cinnamon and orange peel after the second soaking with water to form a coarse slurry. 4.5 times the total mass of hide.

[0038] (4) Fine grinding: Add water to the coarse slurry and then grind it into a fine slurry. The amount of water added is 3 times the mass of the coarse slurry.

[0039]...

Embodiment 2

[0043] Weigh indica rice, dried chili pepper, garlic cloves, fennel, cinnamon bark, orange peel, trehalose and chitosan according to the ratio. :5 mixed indica rice.

[0044] (1) One-time soaking: Soak the indica rice in an aqueous solution of sodium bicarbonate with a mass concentration of 0.3% and a temperature of 30°C for 60 minutes, then drain. The quality of the aqueous sodium bicarbonate solution is three times the mass of indica rice.

[0045] (2) Second soaking: Soak the dried indica rice chili, garlic cloves, fennel, cinnamon bark and orange peel in water at 5°C for 2 hours and drain.

[0046] (3) Coarse grinding: Grind the indica rice, dried chili, garlic cloves, fennel, cinnamon and orange peel after the second soaking with water to form a coarse slurry. 4 times the total mass of the hide.

[0047] (4) Fine grinding: Add water to the coarse slurry and then grind it into a fine slurry. The amount of water added is twice the mass of the coarse slurry.

[0048] (5) ...

Embodiment 3

[0052] Weigh indica rice, dried chili, garlic cloves, fennel, cinnamon bark, orange peel and yam powder according to the proportioning ratio. into a mixed indica rice.

[0053] (1) One-time soaking: Soak the indica rice in an aqueous solution of sodium bicarbonate with a mass concentration of 0.2% and a temperature of 40°C for 30 minutes and then drain. The quality of the aqueous sodium bicarbonate solution is 5 times the mass of indica rice.

[0054] (2) Second soaking: Soak the dried indica rice chili, garlic cloves, fennel, cinnamon bark and orange peel in water at 0°C for 3 hours and then drain.

[0055] (3) Coarse grinding: Grind the indica rice, dried chili, garlic cloves, fennel, cinnamon and orange peel after the second soaking with water to form a coarse slurry. 5 times the total mass of the hide.

[0056] (4) Fine grinding: Add water to the coarse slurry and then grind it into a fine slurry. The amount of water added is 2.5 times the mass of the coarse slurry.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com