High-temperature liquid-phase synthesis method of cadmium telluride powder

A liquid-phase synthesis and cadmium telluride technology, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of inability to realize continuous production, low product purity, long reaction cycle, etc., achieve continuous preparation and short process flow , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

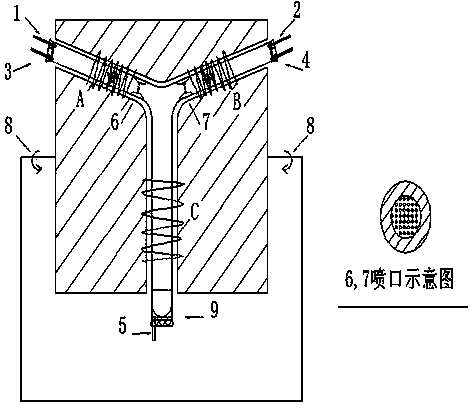

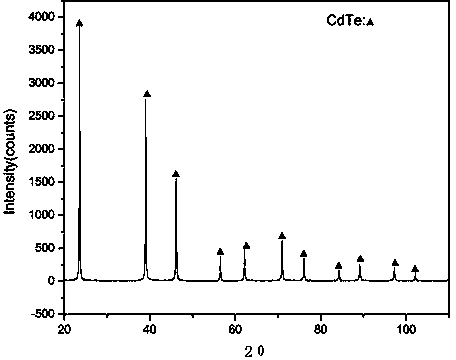

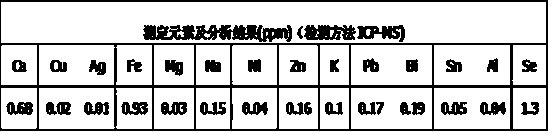

[0017] Put about 1~6mm cadmium block and tellurium block, purity grade 5N, into the A and B ends of the "Y"-shaped tube with a molar ratio of 1:1, the angle between A and B ends is 5°, and the The "Y" shaped quartz tube is placed horizontally into the open and close "Y" shaped furnace with three-stage heating; then the quartz tube is evacuated to 1.0×10 -3 Pa, and heat the A, B, and C sections of the "Y"-shaped quartz tube to 360°C, 480°C and 800°C respectively, and keep warm until the test is completed. After tellurium and cadmium are melted into a liquid, place the three-stage heated open-close furnace vertically through the bracket 8, then close the vacuum valves 1 and 2, open the vent valves 3, 4 and the vent valve 5, and introduce 0.01Mpa Ar gas, so that the tellurium and cadmium liquids are sprayed and atomized from nozzles 5 and 6 respectively. The aperture of the atomized nozzle is 2.0mm. The bottom of the C-end of the Y" shaped quartz tube. After the atomization is ...

Embodiment 2

[0019] Put 3-6mm cadmium block and tellurium block, purity grade 6N, into the A and B ends of the "Y" shaped tube respectively at a molar ratio of 1:1, A, B

[0020] The included angle at both ends is 80°, and the "Y" shaped quartz tube is placed horizontally into the open and close "Y" shaped furnace with three-stage heating; then the quartz tube is evacuated to 1.0×10 -3 Pa, and heat the A, B, and C sections of the "Y"-shaped quartz tube to 370°C, 540°C and 900°C respectively, and keep warm until the test is completed. After tellurium and cadmium are melted into a liquid, place the three-stage heating split furnace vertically through the bracket 8, then close the vacuum valves 1 and 2, open the vent valves 3, 4 and the vent valve 5, and introduce 0.10Mpa Ar gas, so that the tellurium and cadmium liquids are sprayed and atomized from nozzles 5 and 6 respectively. The aperture of the atomized nozzle is 1.0mm. The bottom of the C-end of the Y" shaped quartz tube. After the at...

Embodiment 3

[0024] Put 2~6mm cadmium block and tellurium block, purity grade 7N, into the A and B ends of the "Y"-shaped tube at a molar ratio of 1:1, the angle between A and B ends is 110°, and the " The Y"-shaped quartz tube is placed horizontally into the open-close "Y"-shaped furnace with three-stage heating; then the quartz tube is evacuated to 8.0×10 -4 Pa, and heat the A, B, and C sections of the "Y"-shaped quartz tube to 350°C, 540°C and 600°C respectively, and keep warm until the test is completed. After tellurium and cadmium are melted into a liquid, place the three-stage heating open-close furnace vertically through the bracket 8, then close the vacuum valves 1 and 2, open the vent valves 3, 4 and the vent valve 5, and introduce 0.5Mpa Ar gas, so that the tellurium and cadmium liquids are sprayed and atomized from nozzles 5 and 6 respectively. The aperture of the atomized nozzle is 0.5mm. ”-shaped bottom of the C-terminal of the quartz tube. After the atomization is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com