A method and device for lithium isotope separation and enrichment using membrane extraction

A lithium isotope, separation and enrichment technology, applied in the separation of different isotopic elements, separation methods, dispersed particle separation, etc., can solve the problems of high energy consumption and low efficiency of lithium isotope separation, to avoid difficult enrichment, overcome the release The effect of high heat and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

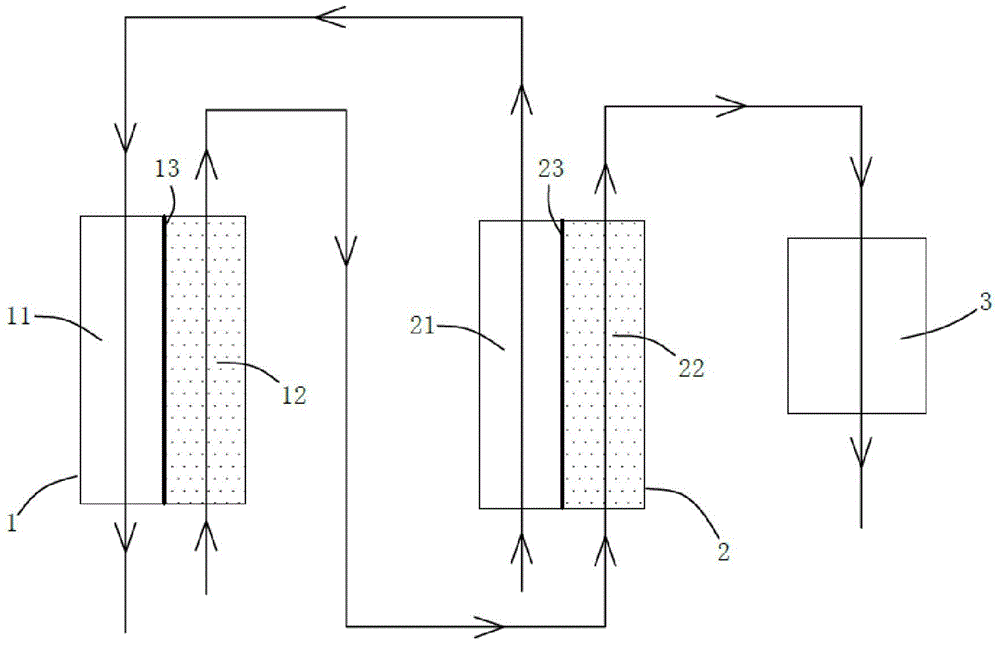

Image

Examples

Embodiment 1

[0034] The polyethylene porous hollow fiber membrane with ion transfer function is prepared into a hollow fiber membrane module. The module parameters are: 12 membrane modules per inch (9 as the membrane extraction stage, 3 as the stripping stage); the module membrane is always effective The area is 9m 2 .

[0035] The extraction agent that has enrichment effect on 7Li is adopted: 1-phenylazo-2-naphthol / methyl trioctyl ammonium chloride, and o-dichlorobenzene is used as the organic solvent; 1-phenylazo in the extraction phase - The concentration of 2-naphthol is 0.4mol / L, and the concentration of methyltrioctylammonium chloride is 0.2mol / L.

[0036] The liquid phase of the material is an aqueous solution of 0.2 mol / L lithium hydroxide and 1 mol / L sodium hydroxide, wherein the lithium element is 7Li and 6Li in natural abundance, which are 0.925 and 0.075, respectively.

[0037] The stripping phase is 1mol / L hydrochloric acid solution.

[0038] The device for membrane extract...

Embodiment 2

[0041] The polytetrafluoroethylene flat membrane with ion transfer function is prepared into a flat membrane module. The module parameters are: 600mm*400mm membrane module number 40 (for the membrane extraction stage), and the total effective area of the module membrane is 10.8m 2 .

[0042] A vibrating sieve tray column with a height of 2000mm and a diameter of 50mm is used as a stripping device.

[0043] The extraction agent that has enrichment effect on 7Li is adopted: 1-phenylazo-2-naphthol / methyl trioctyl ammonium chloride, and o-dichlorobenzene is used as the organic solvent; 1-phenylazo in the extraction phase The concentration of -2-naphthol is 0.4mol / L, and the concentration of methyltrioctylammonium chloride is 0.1mol / L.

[0044] The liquid phase of the material is an aqueous solution of 0.1 mol / L lithium hydroxide and 0.5 mol / L sodium hydroxide, wherein the lithium element is 7Li and 6Li in natural abundance, which are 0.925 and 0.075, respectively.

[0045] The...

Embodiment 3

[0049] The polyethylene vinyl alcohol flat membrane with ion transfer function is prepared into a flat membrane module. The module parameters are: the number of 600mm*400mm membrane modules is 120 (for the membrane extraction stage), and the total effective area of the module membrane is 32m 2 .

[0050] A vibrating sieve tray column with a height of 2000mm and a diameter of 50mm is used as the stripping section.

[0051] The polyethylene vinyl alcohol flat film used in this example is a self-prepared film, and its preparation method is: dissolve 30 grams of ethylene-vinyl alcohol copolymer (in which the ethylene content is 38%) in 70 grams of N,N -In dimethylacetamide, seal and let it stand for 6 hours to defoam, at an ambient temperature of 18.1°C and a humidity of 55%, scrape the obtained homogeneous casting solution on a glass plate with a 200 μm scraper to form a nascent film, and quickly immerse Solidified into a film in a gel bath at 1.5°C, washed with water, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com