A kind of extraction method of pineapple pomace polysaccharide

A technology of pineapple peel residue and extraction method, which is applied in the direction of anti-toxic agent and drug combination, can solve the problems of large investment in equipment and high operation requirements, and achieve the effects of less loss of nutrients, high yield of polysaccharides, and strong antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

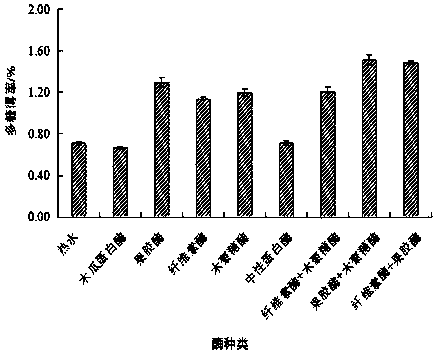

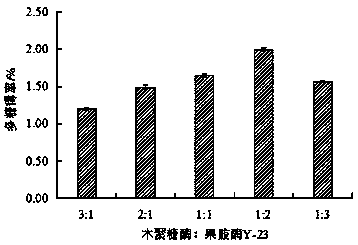

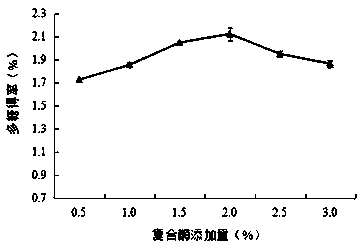

Method used

Image

Examples

Embodiment 1

[0068] Example 1 Take 5g dry powder of pineapple pomace, add 150mL distilled water, 1.5% compound enzyme (xylanase: pectinase Y-23 mass ratio = 1:2), keep the natural pH of the extract (6.0), and spin Carry out the hydrolysis reaction in an evaporator, control the enzymolysis temperature at 50°C, the enzymolysis time for 2 hours, and the rotation speed at 130rpm / min. After the extraction, the enzyme is quenched in a boiling water bath for 10 minutes, centrifuged at 8000rpm for 10 minutes, the supernatant is taken, and the residue is added to 150mL of distilled water. Transfer it to a water bath for leaching at 100°C for 2 hours, centrifuge at 5000 rpm for 10 minutes after the extraction, take the supernatant, and repeat the extraction of the residue once. Concentrate the volume of the extract to 1 / 5 of the original volume by evaporation under reduced pressure, add 4 times the volume of 95% ethanol to the concentrate, let it stand overnight at 4°C, centrifuge at a speed of 5000r...

Embodiment 2

[0069] Example 2 Take 5g of pineapple pomace dry powder, add 150mL of distilled water, 2.0% compound enzyme (xylanase: pectinase Y-23 mass ratio = 1:2), keep the natural pH of the extract (6.0), and spin Carry out the hydrolysis reaction in the evaporator, control the enzymolysis temperature to 50°C, enzymolysis time to 1.5h, and the rotation speed to 130rpm / min. After the extraction is completed, the enzyme is inactivated in a boiling water bath for 10min, centrifuged at 6000rpm for 10min, the supernatant is taken, and the residue is added to 200mL of distilled water. Transfer it to a water bath for leaching at 100°C for 2 hours, centrifuge at 5000 rpm for 10 minutes after the extraction, take the supernatant, and repeat the extraction of the residue once. Concentrate the volume of the extract to 1 / 5 of the original volume by evaporation under reduced pressure, add 4 times the volume of 95% ethanol to the concentrate, let it stand overnight at 4°C, centrifuge at 4500r / min for ...

Embodiment 3

[0075] Embodiment 3 adopts the following steps to realize the present invention:

[0076] (1) Pretreatment: Freeze-dry the screened pineapple pomace, powder it, and pass through a 40-mesh sieve to obtain pineapple pomace dry powder; freeze-drying conditions: temperature -40°C, pressure 6Pa, time 24h;

[0077] (2) Degreasing: Put the dry powder of pineapple skin dregs obtained in step (1) into a container, add petroleum ether with a boiling range specification of 30-60°C to reflux and extract for 3 times, collect the filter residue, and dry it naturally for later use;

[0078] (3) Enzymatic hydrolysis of raw materials: add distilled water to the pineapple pomace powder prepared in step (2) at a ratio of 1:40g / mL to liquid, and at the same time add 2.2% compound enzyme (xylanase: pectinase Y- 23 mass ratio = 1:3), at 53°C, pH 6.0 in a water bath, carry out enzymatic hydrolysis in a rotary evaporator with a rotational speed of 130r / min for 2.1h, after enzymatic hydrolysis, boil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com