Preparation method of water-soluble carbon quantum dots

A carbon quantum dot, water-soluble technology, applied in the field of preparation of water-soluble carbon quantum dots, can solve the problems of high cost, high equipment requirements, inconvenient operation, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

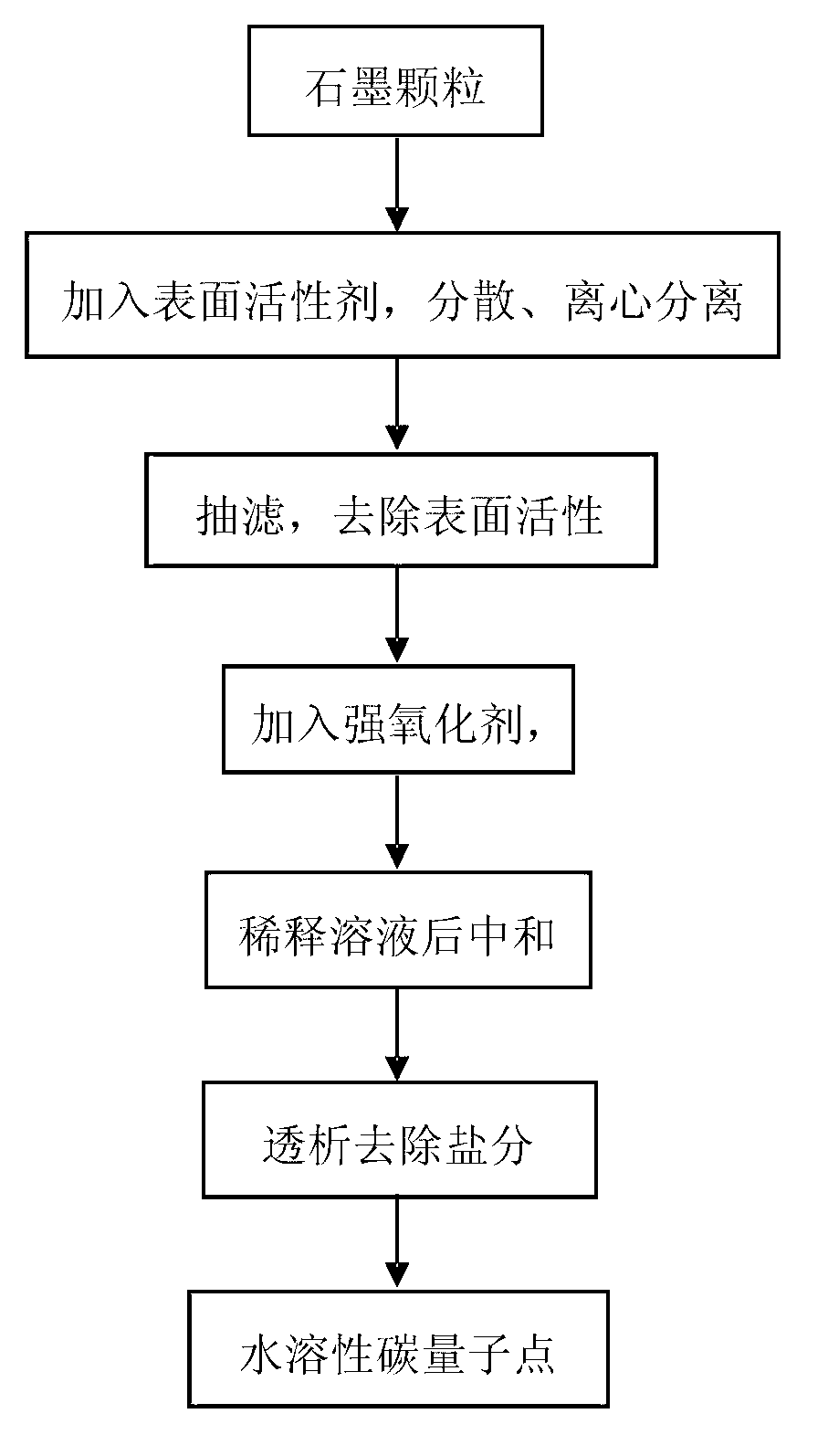

Method used

Image

Examples

Embodiment 1

[0026] The graphite impurity produced by the arc method to prepare single-walled carbon nanotubes is dissolved in an aqueous solution containing 1wt% sodium dodecyl sulfate (the mass ratio of the graphite impurity to the aqueous solution of sodium lauryl sulfate is 0.5: 100), and Ultrasonic dispersion was performed for 1 h, and then centrifuged at 3000 rpm, and the obtained supernatant was centrifuged at 6000 rpm, the precipitate was taken out, and the surfactant was removed by suction filtration. Mix the obtained graphite particles with sulfuric acid / nitric acid (v / v=3:1) at a ratio of 0.5ml / mg (approximately 0.01mmol / mg), and heat it to 150°C in an oil bath to carry out oxidation reflux reaction, and the reaction is carried out for 30 hours , remove the solution and dilute it 10 times with deionized water, then add NaCO 3 Neutralize until the pH value of the solution is 7, and finally dialyze the obtained solution with a dialysis bag with a cut-off of 2000 for 3 days to obta...

Embodiment 2

[0028] The graphite impurity produced when the single-walled carbon nanotube is prepared by the electric arc method is dissolved in an aqueous solution containing 1wt% sodium lauryl sulfate (the mass ratio of the graphite impurity to the aqueous solution of sodium lauryl sulfate is 0.05: 100), Ultrasonic dispersion was carried out for 1 h, and then centrifuged at 17000 rpm, the obtained supernatant was centrifuged at 20000 rpm, and the precipitate was taken out and sodium lauryl sulfate was removed by suction filtration. The obtained graphite particles were mixed with sulfuric acid / nitric acid (v / v=3:1) at a ratio of 0.5ml / mg (approximately 0.01mmol / mg), heated to 200°C in an oil bath for oxidation and reflux reaction, and the reaction was carried out for 40 hours. Take out the solution and dilute it 10 times with deionized water, then add NaOH to neutralize the solution until the pH value is 7, and dialyze the resulting solution with a dialysis bag with a cutoff of 2000 for 3 ...

Embodiment 3

[0030] Dissolve the graphite impurities produced by the arc method in the preparation of single-walled carbon nanotubes in an aqueous solution containing 1wt% sodium dodecyl sulfate, ultrasonically disperse for 1 hour, and then centrifuge at a speed of 12000rpm, and then centrifuge the obtained supernatant at a speed of 15000rpm , the precipitate was taken out and the sodium lauryl sulfate was removed by suction filtration. Mix the obtained graphite particles with concentrated nitric acid at a ratio of 0.5ml / mg (approximately 0.01mmol / mg), heat it to 150°C in an oil bath to carry out oxidation reflux reaction, and carry out the reaction for 5 hours, take out the solution and dilute it 10 times with deionized water , and then add NaOH to neutralize the solution until the pH value is 7, and use a dialysis bag with a cutoff of 3000 to obtain the water-soluble carbon quantum dots, and the particle size range is 10-15nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com