Food waste separating apparatus

A separation device, catering waste technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as dehydration, reduce concentration polarization, prevent material liquid The effect of increasing the concentration and enhancing the oil-water separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

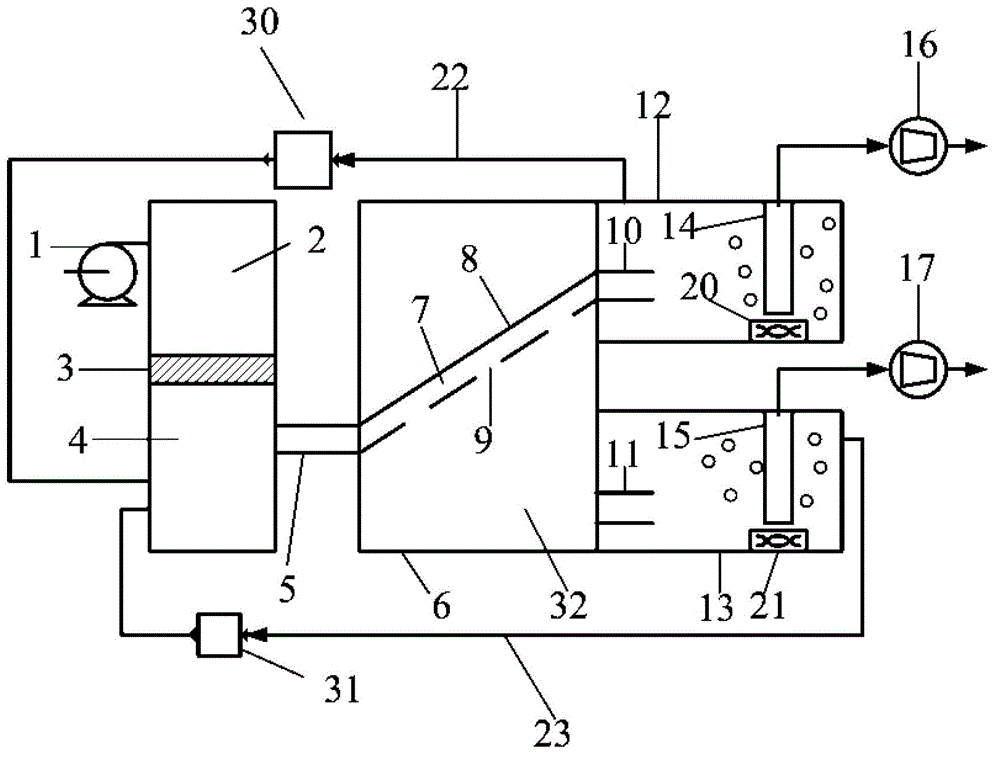

[0028] Such as figure 1 As shown, a kind of catering garbage separation device provided by the present invention comprises: feed pump 1, solid-liquid separation unit 2, oil-water preliminary separation unit 6, waste oil separation unit 12, waste water separation unit 13, is characterized in that: feed The pump 1 is connected to the solid-liquid separation unit 2 . A solid-liquid separation device 3 is included in the solid-liquid separation unit 2, and the permeation side of the solid-liquid separation device 3 is a feed-liquid tank 4, and the feed-liquid tank 4 is connected to the oil-water preliminary separation unit 6 through a feed pipe 5; The unit 6 includes a separator 7, the separator 7 is composed of an upper plate 8 and a lower plate 9, the upper plate 9 has holes, the lower plate 9 is a cavity 32, and the separator outlet 10 is connected to the waste oil separation Unit 12, the cavity outlet 11 is connected to the wastewater separation unit 13; the waste oil separat...

Embodiment 2

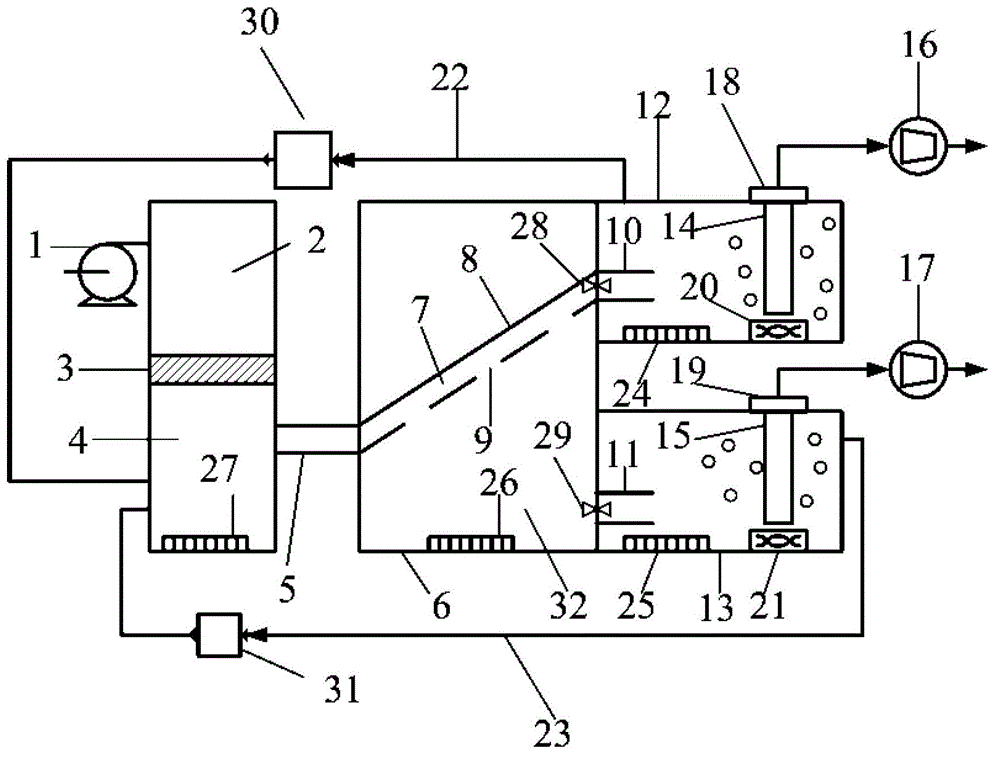

[0034] Such as figure 2 As shown, a kind of catering garbage separation device provided by the present invention comprises: feed pump 1, solid-liquid separation unit 2, oil-water preliminary separation unit 6, waste oil separation unit 12, waste water separation unit 13, is characterized in that: feed The pump 1 is connected to the solid-liquid separation unit 2 . A solid-liquid separation device 3 is included in the solid-liquid separation unit 2, and the permeation side of the solid-liquid separation device 3 is a feed-liquid tank 4, and the feed-liquid tank 4 is connected to the oil-water preliminary separation unit 6 through a feed pipe 5; The unit 6 includes a separator 7, the separator 7 is composed of an upper plate 8 and a lower plate 9, the upper plate 9 has holes, the lower plate 9 is a cavity 32, and the separator outlet 10 is connected to the waste oil separation Unit 12, the cavity outlet 11 is connected to the wastewater separation unit 13; the waste oil separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com