Method and device for realizing soybean protein separation by two mediums-mixed leaching

A soybean protein extraction technology, applied in the field of refining and extraction, can solve the problems of increasing investment in fixed assets and energy consumption, failing to meet the requirements of the alcohol extraction process, and reducing the utilization rate of raw materials, so as to benefit physical and mental health, reduce energy consumption, and protect environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

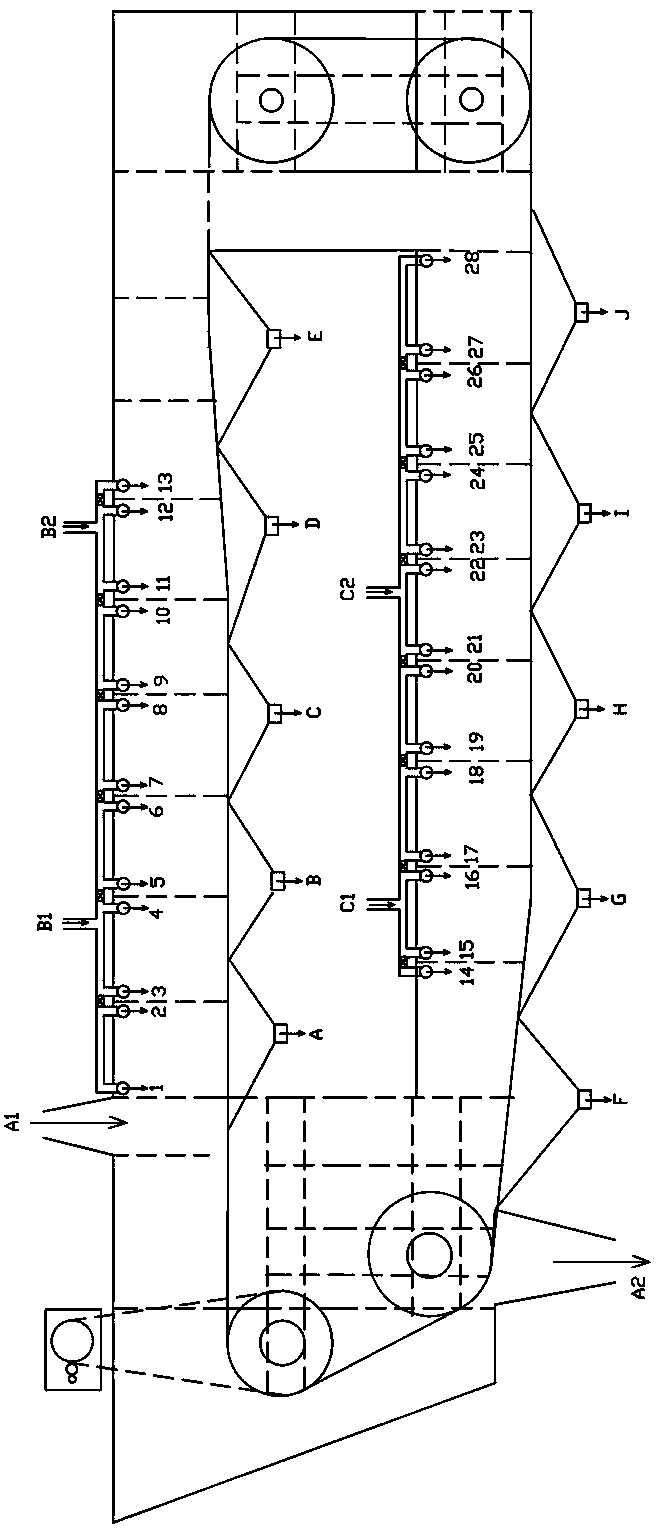

Image

Examples

Embodiment Construction

[0033] The method of the present invention to realize the separation of soybean protein by mixing and leaching two kinds of media is developed according to the principle of solid-liquid extraction. It is based on the property that n-hexane can be miscible with oil, and the protein raw material embryo is processed by using n-hexane solvent. The spraying and soaking of the slices extracts the fat in the protein raw material embryo slices.

[0034] Soluble protein in soybean meal flakes can be dissolved in water, but not in ethanol, and when the concentration of ethanol is greater than 65% volume fraction, the solubility of soluble protein is the lowest. Some odor components and pigments have better solubility. Oligosaccharides, saponins, isoflavones, lipids, polyphenols, acetaldehyde, and acids in low-temperature soybean meal are easily dissolved in ethanol solutions with a volume fraction concentration greater than 65%, and at this time the solubility of soluble proteins is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com