Corrosion-resistant nickel-base alloy overlay welding powder

A technology of nickel-based alloy and alloy powder, which is applied in welding medium, welding equipment, metal processing equipment, etc., can solve problems such as poor effect, and achieve the effect of improving service life and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A corrosion-resistant nickel-based alloy surfacing welding powder, by weight %, has the following composition:

[0018] Cr 20 Mo 10 Co 6 Zr 0.5Re 0.5 Mn 1 Si2

[0019] B1.5 Ni balance impurity content 0.05

Embodiment 2

[0021] A corrosion-resistant nickel-based alloy surfacing welding powder, by weight %, has the following composition:

[0022] Cr 24 Mo 12 Co 7 Zr 0.8 Re 0.8 Mn 1.2 Si 2.3

[0023] B 1.8 Ni balance impurity content 0.05

Embodiment 3

[0025] A corrosion-resistant nickel-based alloy surfacing welding powder, by weight %, has the following composition:

[0026] Cr 28 Mo 14 Co 8 Zr 1 Re 1 Mn 1.5 Si 2.5

[0027] B2 Ni balance impurity content 0.05

[0028] In Examples 1, 2 and 3, Ni:Co is 5:1-10:1; Cr:Mo is 2:1; in the process of making alloy powder, Mn, Zr, Re are added one by one according to this order.

[0029] The corrosion-resistant nickel-based alloy surfacing welding powder of the invention is produced by melting in an induction heating furnace and atomizing high-purity nitrogen gas. The powder appearance is silver-gray, the spherical particle powder has good fluidity (14s / 50g), and the bulk density is high (4.6g / cm 3 ), the oxygen content is less than or equal to 500PPM, and the desirable particle size range is 212-20μm.

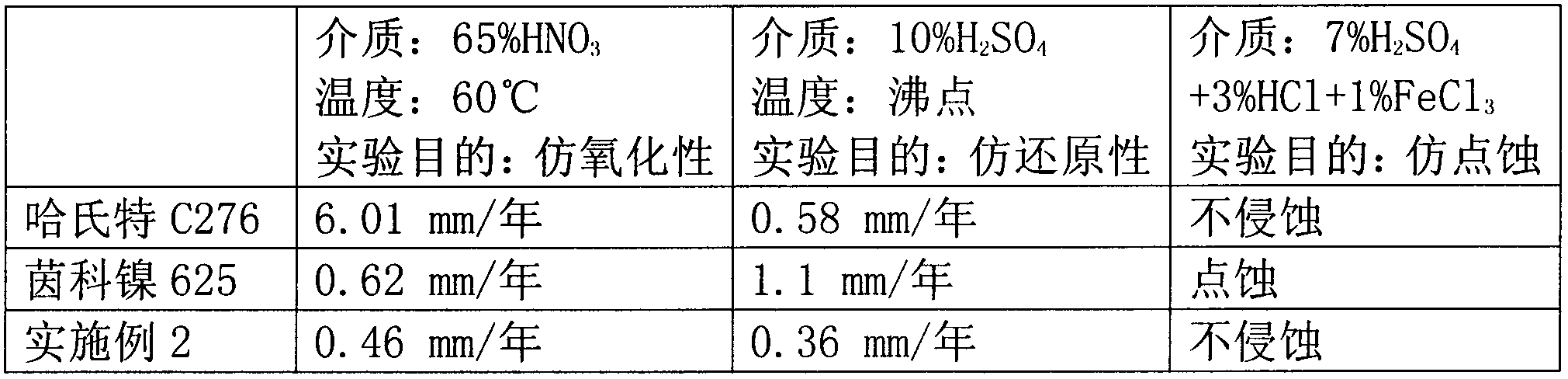

[0030] The embodiment 2 of the corrosion-resistant nickel-based alloy surfacing welding powder of the present invention is compared with Hastelloy C276 and Inconel 625 alloys in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com