Electrical energy copy increment technology

An electric energy, incremental technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problem of no effective power and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

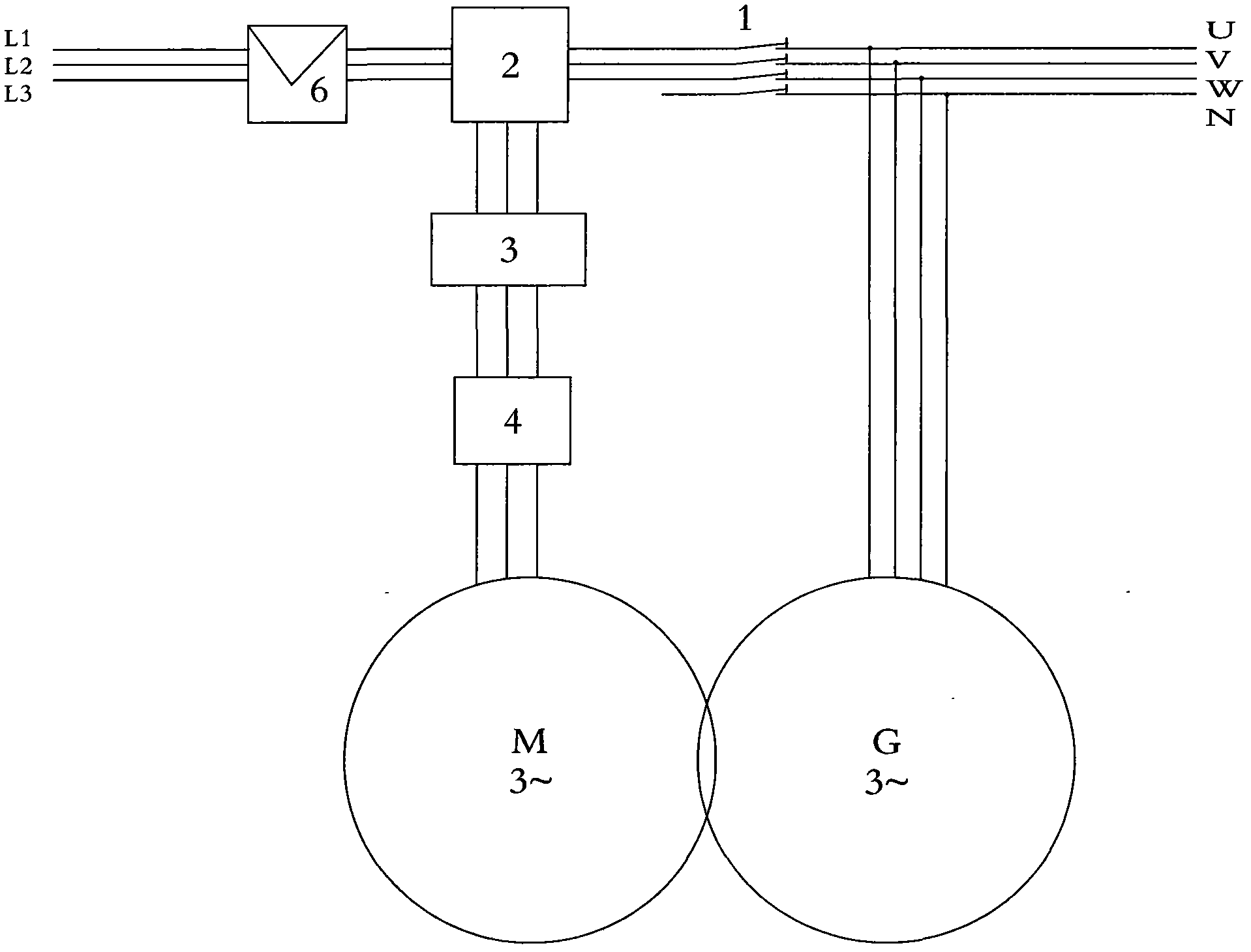

[0016] Example 1: In figure 1Among them, (1) is a normally closed switch. The external starting power is connected to the input terminal of the starter (6), the switch of the starter is turned on, the starting power passes through the starter (6), the normally closed contact of the voltage relay (2), the motor speed control system (3), and the motor protection The system (4), flows to the motor group (M) of the self-rotating unit (MG), starts the unit to run, and the power generated by the generating group (G) passes through the switch (1) to the normally open contact of the voltage relay (2) , when the power supply voltage generated by the generating set (G) rises to the setting value of the voltage relay, the voltage relay will automatically work to close the normally open contact and open the normally closed contact, and the power supply will pass through the voltage relay (2), the motor speed The control system (3), the motor protection system (4) and the motor group (M) ...

example 2

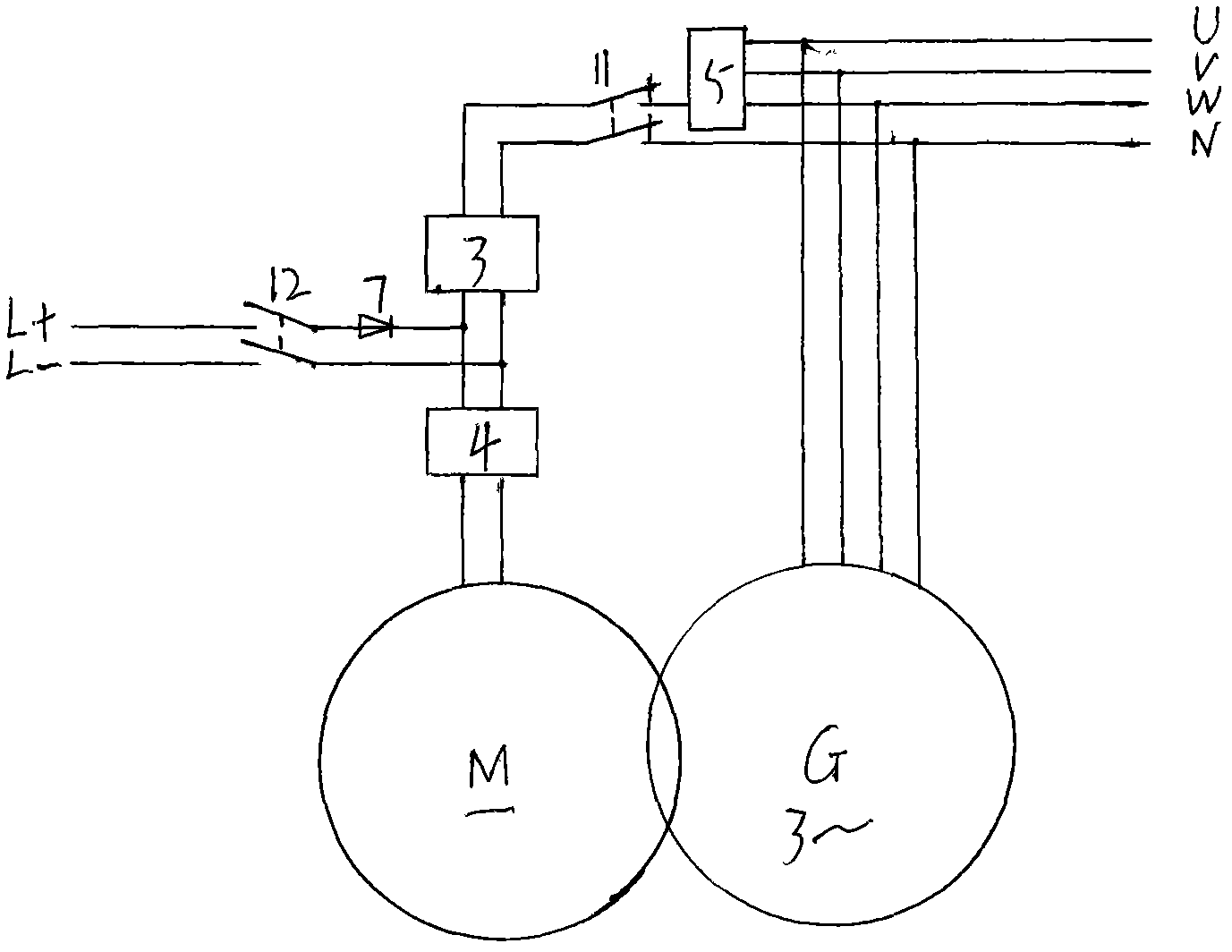

[0017] Example 2: In figure 2 Among them, (11) is a normally closed switch. The external starting power supply is connected to the input end of the switch (12), and the switch (12) is closed. The external starting power supply passes through the switch (12), the diode (7), and the motor protection system (4) to the motor group ( M) Start the unit to run, and the AC power generated by the generating set (G) is rectified into a DC power supply through the bridge rectifier system (5), and then passed through the switch (11), the motor speed control system (3), and the motor protection system (4) To the motor group (M) of the autorotation unit (MG) for self-circulation operation. When the operation of the unit can be self-circulating, the switch (12) is turned off to make the unit do self-circulating. Because the bridge rectifier system (5) has a blocking effect, the external starting power will not flow to the generating set (G) of the self-rotating unit.

example 3

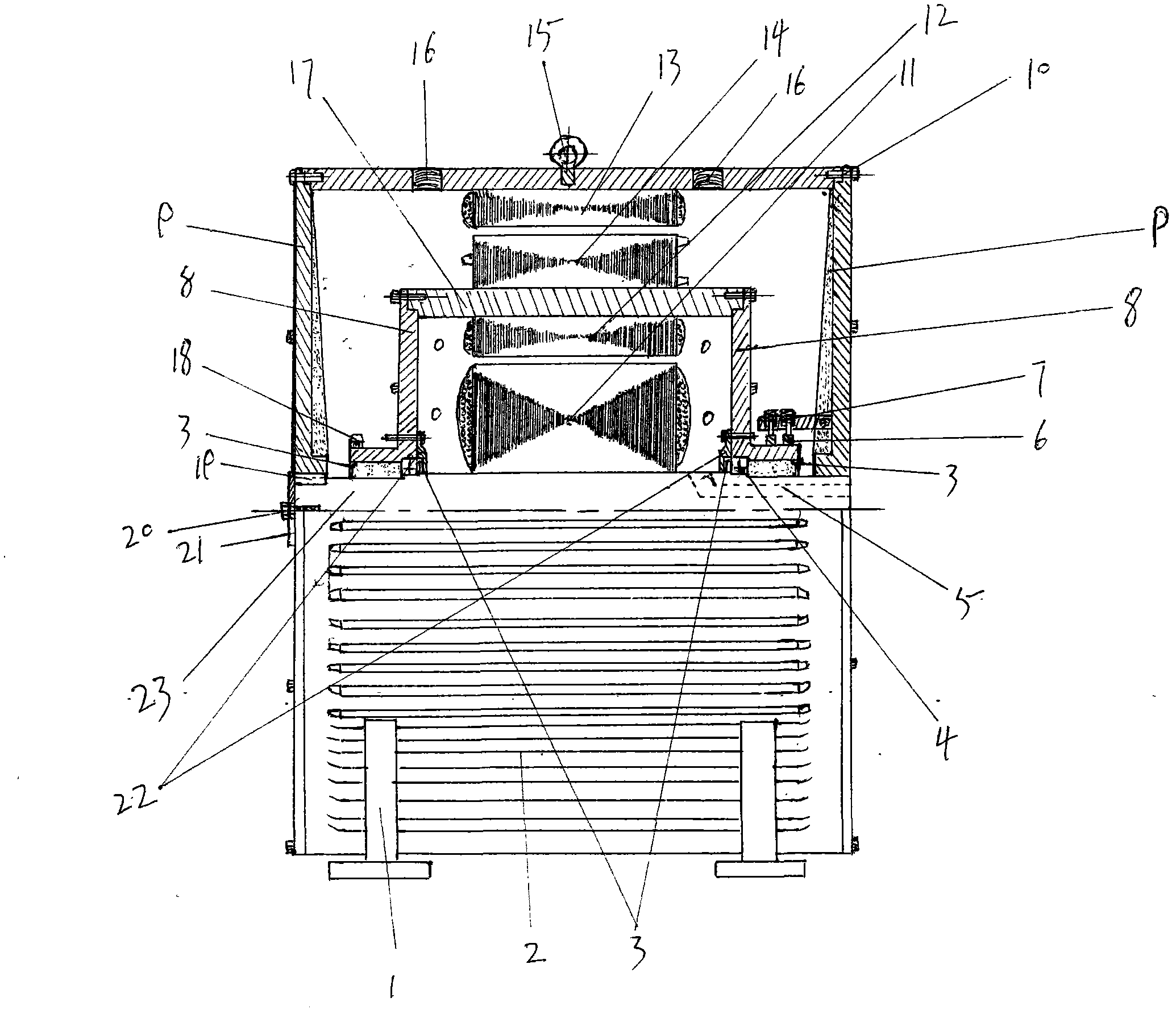

[0018] Example 3: This example is an example of using compressed air to start the operation of the self-rotating unit without starting the power supply. exist image 3 Middle: The air motor is installed on the end cover of the machine base, and the motor is driven by compressed air, so that the telescopic gear of the motor meshes with the ring gear (18) on the support plate of the sleeve swivel, driving the sleeve swivel (17) Rotating around the anti-rotation shaft (23), the rotor group (12) of the generating set on the inner wall of the pipe sleeve rotor (17) and the stator group (11) on the anti-rotation shaft (23) generate electromotive force to generate current, and its power supply current is from A circuit element (eg figure 1 , figure 2 ) to the stator group (13) of the electric group, so that the stator winding (13) of the electric group is energized to generate a magnetic field, and the rotor group (14) of the electric group cuts the magnetic field lines in the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com