SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) combined denitration method and SNCR and SCR combined denitration device for flue gas of coal-fired boiler

A technology for coal-fired boilers and SCR reactors, which is applied in the field of flue gas purification, can solve the problem of inability to measure the reducing dose, and achieve the effects of convenient operation, reduced operating costs, and reduced equipment space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

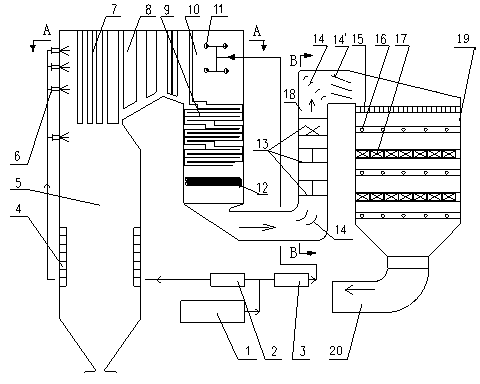

[0027] Combine below figure 1 The device illustrates the implementation method of the combined SNCR and SCR denitrification of the present invention.

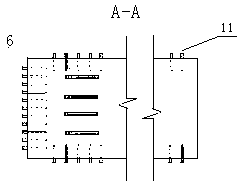

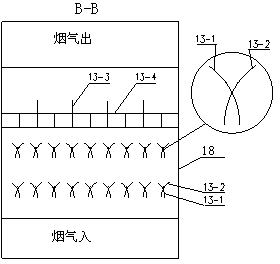

[0028] Such as figure 1 , the boiler 5 is equipped with a burner 4, coal combustion produces flue gas, and the nitrogen oxide (NOx) content in the flue gas is 450mg / Nm 3 , the flue gas goes upward through the refraction angle of the furnace (that is, the right position above the boiler 5) and enters the space area of the superheater 7, where the flue gas temperature is 850-1050 °C, which is the "temperature window" suitable for SNCR. The front and side walls of this temperature window (see figure 2 ) are equipped with a reducing agent spray gun 6, and the material of the spray gun is 316L stainless steel. figure 1 It shows that the reducing agent spray gun 6 is arranged in four layers from bottom to top, and the elevations of each layer located in the boiler are respectively 35.8m, 43.192m, 46.592m, and 49.092m. see fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com