Ultrathin halogen-free flame retardant polycarbonate film and preparation method thereof

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the field of polycarbonate film and its preparation, can solve the problems of polycarbonate film that cannot reach the flame-retardant level, reduce flame retardancy, and poor support, and achieve excellent appearance, High flame retardant efficiency and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

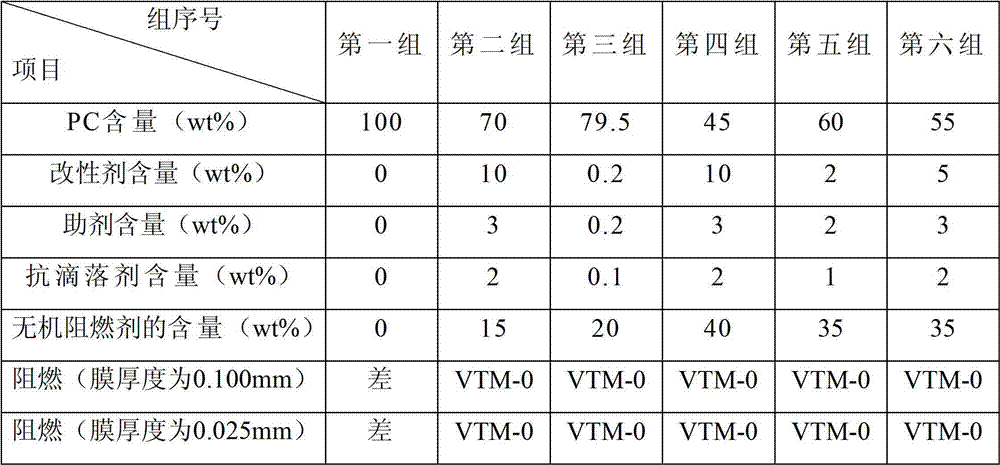

Embodiment 1

[0027] The mass percentage of polycarbonate resin is 45% to 99%.

[0028] The flame retardant used in the halogen-free flame retardant system is an inorganic flame retardant, and its mass percentage is 0.5% to 40%, and the preferred range is 15% to 40%.

[0029] The mass percentage of the anti-dripping agent is 0.1% to 2%.

[0030] The modifier is one or more of the toughening agent, flame retardant synergist, flame retardant and smoke suppressor, ultraviolet absorber, impact modifier and antistatic agent, and the mass percentage is 0.2% to 10% %.

[0031] The auxiliary agent is one or more of thermo-oxygen stabilizer, light stabilizer, dispersant, compatibilizer and colorant, accounting for 0.2% to 3% by mass.

[0032] The preparation method step of ultra-thin halogen-free polycarbonate film in the present embodiment is as follows:

[0033] a) Preparation of flame retardant polycarbonate masterbatch

[0034] Pre-dry polycarbonate, halogen-free flame retardant, anti-drippi...

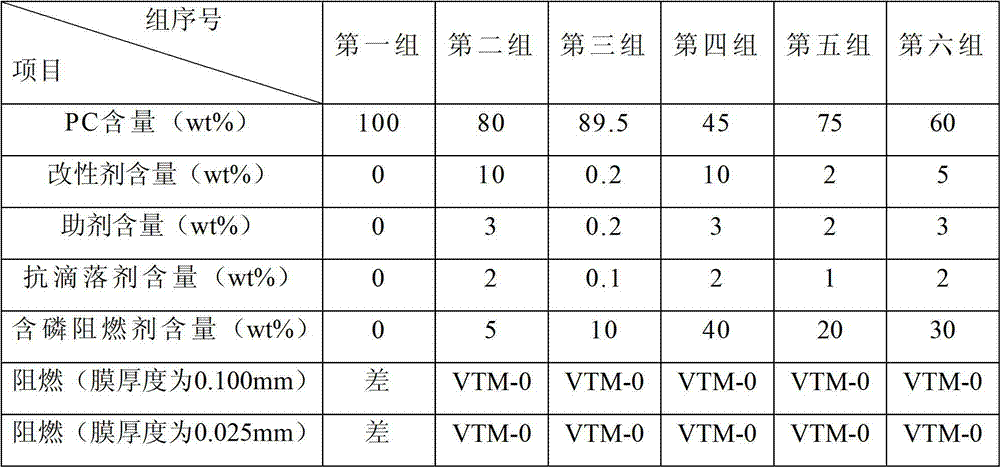

Embodiment 2

[0041] The mass percentage of polycarbonate resin is 45% to 99%.

[0042] The flame retardant used in the halogen-free flame retardant system is a phosphorus-containing flame retardant, and its mass percentage is 0.5% to 40%, and the preferred range is 5% to 40%.

[0043] The mass percentage of the anti-dripping agent is 0.1% to 2%.

[0044] The modifier is one or more of the toughening agent, flame retardant synergist, flame retardant and smoke suppressor, ultraviolet absorber, impact modifier and antistatic agent, and the mass percentage is 0.2% to 10% %.

[0045] The auxiliary agent is one or more of thermo-oxygen stabilizer, light stabilizer, dispersant, compatibilizer and colorant, accounting for 0.2% to 3% by mass.

[0046] The preparation method of the ultra-thin halogen-free polycarbonate film in this example is the same as that in Example 1.

[0047] The flame retardant is a phosphorus-containing flame retardant, and the ultra-thin halogen-free polycarbonate film i...

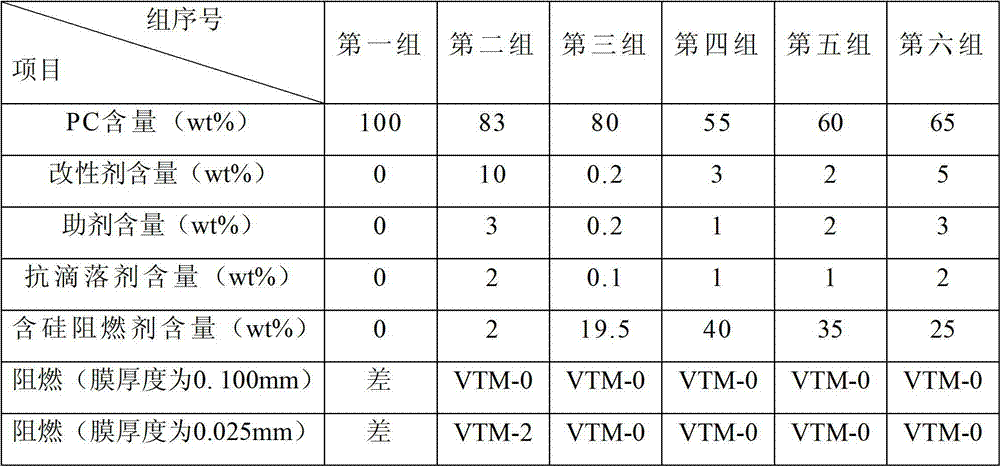

Embodiment 3

[0051] The mass percentage of polycarbonate resin is 45% to 99%.

[0052] The flame retardant used in the halogen-free flame retardant system is a silicon-containing flame retardant, and its mass percentage is 0.5% to 40%, and the preferred range is 2% to 40%.

[0053] The mass percentage of the anti-dripping agent is 0.1% to 2%.

[0054]The modifier is one or more of the toughening agent, flame retardant synergist, flame retardant and smoke suppressor, ultraviolet absorber, impact modifier and antistatic agent, and the mass percentage is 0.2% to 10% %.

[0055] The auxiliary agent is one or more of thermo-oxygen stabilizer, light stabilizer, dispersant, compatibilizer and colorant, accounting for 0.2% to 3% by mass.

[0056] The preparation method of the ultra-thin halogen-free polycarbonate film in this example is the same as that in Example 1.

[0057] The flame retardant is a silicon-containing flame retardant, and the ultra-thin halogen-free polycarbonate film is prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com